Good news! If your lifeless locomotive has ever run under Digital Command Control (DCC), chances are good that you can get it running again without having to send it off for repair. The solution is easy, too!

More good news! If you have a new steam locomotive that doesn’t run or only partially works, maybe all that’s wrong is that the connector between the engine and tender isn’t seated correctly. Make sure the connector is oriented correctly and pushed all the way in. Just be careful not to damage the wires when doing this.

Let me be specific about which locomotives can easily be brought back to life. A locomotive that ran on address 3 out of the box has hope. A locomotive that you or someone else put a decoder in and ran on address 3 also has hope. Locomotives that ran before a decoder was put into them, but not after, may need more help than I can cover in this column.

Before you get started, make sure you have track power. Check your track status light, try another locomotive, or short the track and see if your booster (or electronic circuit breaker, if you are using one) trips.

If the locomotive has run before, maybe it’s not on the address you think it is. Or the locomotive might have been part of a consist. Sometimes there can be a mix-up with short versus long addressing. The locomotive may have been inadvertently shut down. Finally, one or more CVs (Configuration Variables) may have accidentally been set to something that renders the locomotive inoperable. Less common is that your speed steps may have changed for your throttle. I’ll address each of these.

Usually, when someone gives me a DCC locomotive that doesn’t run, all they can tell me is that it doesn’t run any more. They usually also can’t tell me what manufacturer’s decoder is in it. I will try to determine if it has been reset and check to see if it responds to the default address of 3. If I can’t do that, then I do a factory reset. Here’s how to do these things.

First, there are a couple of things you need to know. There are generally two ways to program a locomotive. Programming on the main only works if you know the address of the locomotive. If you knew this, you probably wouldn’t have a problem with your locomotive. Programming on a programming track doesn’t require you to know the address. The reason programming on the main requires you to use the address is so you don’t reprogram your entire layout.

First try the locomotive to see if it was inadvertently reset and will respond to address 3. If that doesn’t work, are you entering a leading 0 – that is, 03 instead of just 3? For example, NCE allows you to do either, but when you do, it treats them differently. So if you entered 03, try just 3.

If address 3 works, you’re probably relieved that you won’t have to send back your locomotive for servicing. If it doesn’t work, there are other things that might be at issue. You can address these other issues, but if the locomotive is new and you haven’t configured it or set up speed tables, it’s easy to do a factory reset.

If a dead locomotive doesn’t respond to the cab number or address 3, I do a factory reset. Often, in less than 5 minutes, it’s running again. Then I set the address to its cab number.

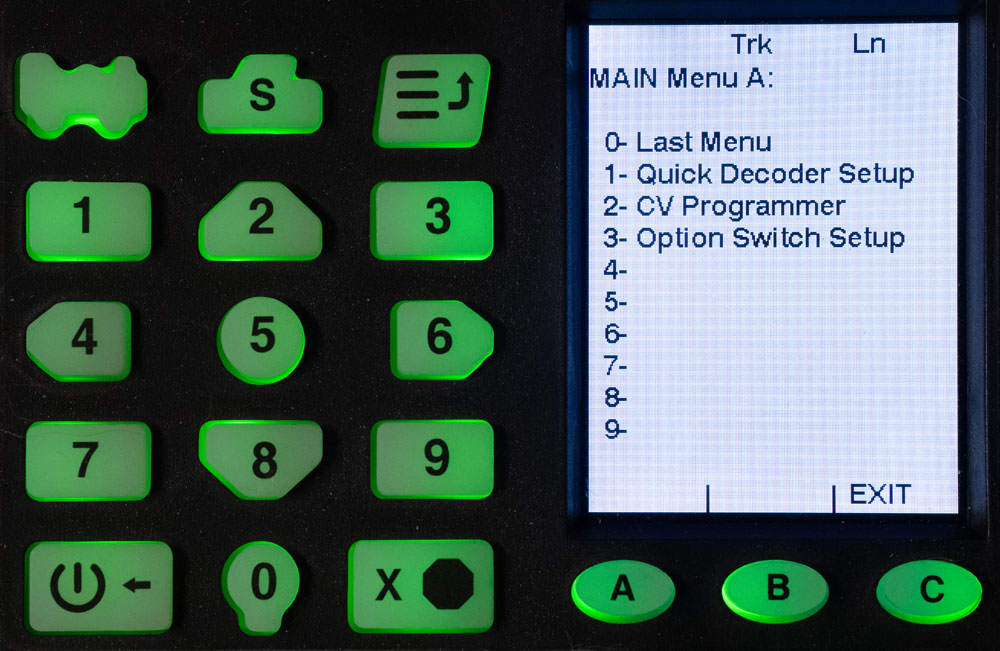

Before you do a factory reset, you need a programming track. Except for the very basic starter systems, most systems provide for a programming track. The NCE PowerCab, when not used with its AutoSwitch, combines programming and mainline on the same output. If you don’t have an AutoSwitch, make sure no other engines are on the track when you go to program mode.

When you do a factory reset, the decoder will be reset to the way it was when you took it out of the box. You will lose your speed table settings, any configuring of sound settings like the bell or whistle, and any address you set it to. If it was part of a consist, you’ll lose that, too. More on consists in a bit.

I’ve seen at least one decoder that allows you to do a factory reset while keeping your speed table. If you have a speed table set up, you might want to check your decoder’s manual or the manufacturer’s website and see if a factory reset can be done without losing your speed table. Though a screwed-up speed table is one reason a locomotive might not run.

Another way to trim the speed of a locomotive is adjusting CVs 5 and 6. These are “Voltage high” and “Voltage mid,” respectively. If you changed the values in these CVs, this is where you may have gone wrong. To fix this, set CV 5 = 255 and CV 6 = 128.

Almost all decoders can be factory reset by setting CV 8 to a value of 8. Easy enough to remember. I can only recall one decoder that was reset differently. Check the decoder manual or manufacturer’s website. But if you want to do a factory reset, there’s no harm in trying CV 8 = 8. I also recall seeing a decoder that if you set CV 8 = 9, it would retain your speed table. So if you have set a speed table, you can try that.

Programming on the main, also known as ops or operations mode programming, requires you to know the locomotive’s address, but all other programming modes do not. All systems that offer programming capability give you at least two choices. Other than ops mode, you will often have the choice of direct mode or page mode. Some decoders are picky, but try direct mode first; that is the most prevalent mode now.

Here is how you do a factory reset. Just enter programming, select direct or page if given a choice, and select programming a CV. Select CV 8 and then enter 8 for the data for that CV. The locomotive may move slightly or make a sound acknowledging the command. Now try selecting address 3, and your locomotive should run again.

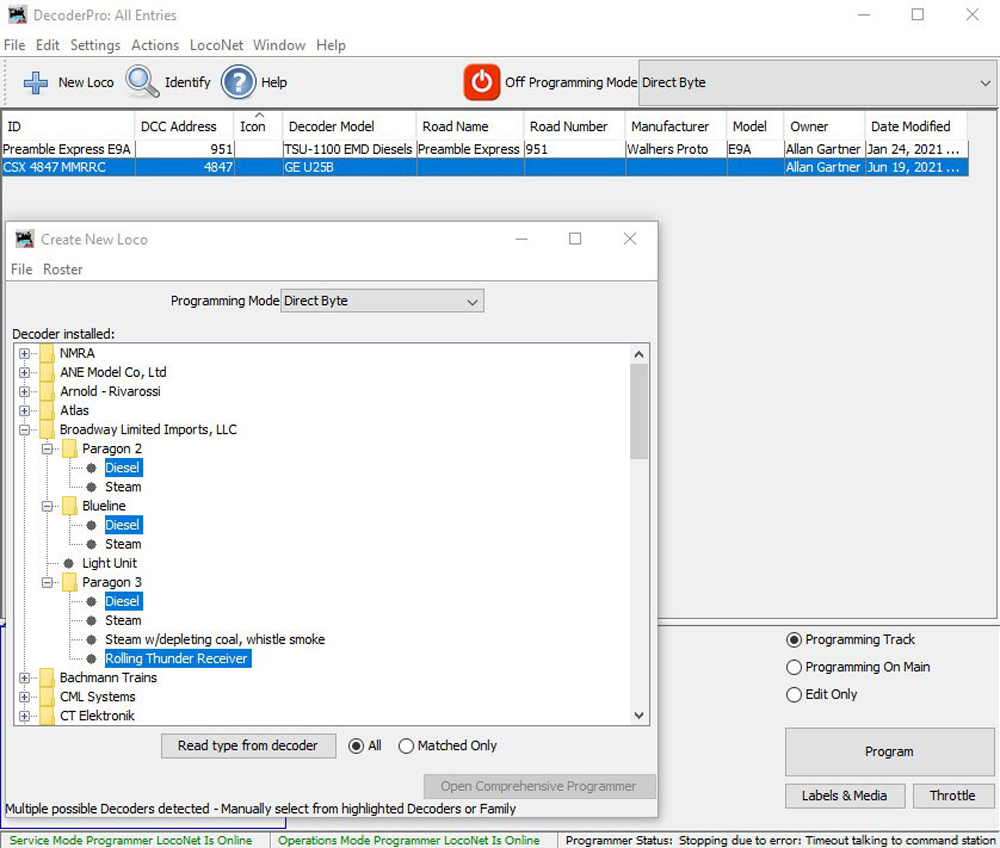

Now breathe a sigh of relief and set your locomotive to the address of your choice. Don’t enter a leading zero. Most systems provide an easy way to set your locomotive’s address. Especially when setting a long address (128 or higher), multiple CVs are involved. So follow your DCC equipment manufacturer’s procedure that sets the various CVs for you correctly and easily. You can also use DecoderPro if you have a computer connected to your DCC system. DecoderPro is part of the free Java Model Railroad Interface suite of software. You can download it at jmri.org.

There are a few other possibilities that may make your locomotive unresponsive that you can try before doing a factory reset. If your locomotive doesn’t run, but did and was part of a consist, it may think it’s still part of the consist. Call up that consist on your system and then break up the consist. The address you normally use for that locomotive should work again without doing a factory reset.

Another reason for a now seemingly dead locomotive may be that you shut it down. This feature is built into many sound decoders so you don’t have to listen to a lot of locomotives all making sound at once. It also allows you to start it up with a sound sequence. When shut down, besides not making sounds, the locomotive will also not run. It depends on the manufacturer, but sometimes pressing F6, F8, or F9 will shut down the locomotive. Pressing the correct function key again will start it up.

Now that you have resurrected your locomotive from the dead, save that box and bubble wrap for something else you might need to ship!