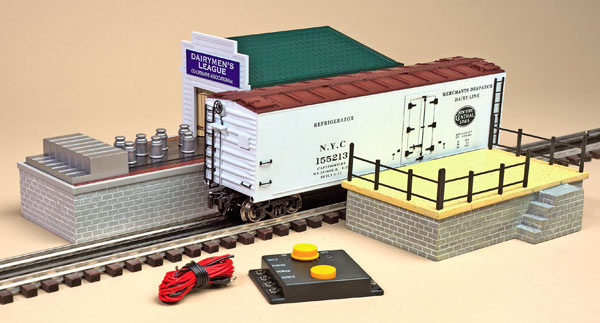

We first tested the no. K-703-1751 operating milk car with unloading platform. Shortly after, the K-42407 operating milk loading depot arrived in the mail. Putting the two together in a review is a natural fit.

First, the unloader. K-Line’s re-working of the venerable Lionel operating milk car is an easy way to incorporate an action-generating freight car on a layout without necessarily installing a special section of track.

The unloader outfit includes the car, milk containers, and a K-41817 unloading platform, which serves as a nice loading dock for a train or truck.

Activation can be accomplished conventionally (by installing a Lionel-style “UCS” remote-control track section, which must be purchased separately) or, better still, by wireless remote using a K-Line K-712RC remote controller (which also is purchased separately).

The milk reefer car has an internal conveyor that moves milk cans into position and ejects them on command. To operate the car with K-Line’s remote controller (instead of a special section of track), you will need to set a unique address for the reefer. This is done through setting positions on two rows of switches beneath the car. One row has the letters A, B, C and the other row has the numbers 1-8. You can set your car identity, for example, as “A 6.”

Once the car is on a “live” track, powered by 8-20 volts, it responds to the commands sent from the remote. For example, by punching “A” and “6” the car will go through one complete unloading cycle. Subsequent commands will unload one additional can.

For use with a special track section, place the center of the car over the uncoupler activator and hit the button.

Second is the K-Line milk car loader. This is one of those rare opportunities for a railroader to place the loader at one spot on his line and the unloader on another, and actually move cargo from point “A” to point “B.”

The loader requires a straight section of track with roughly 12 by 4 inches of free space for the building. The instructions for hooking up power and controls are clear and straightforward.

The structure comes with plate shims for O or O-27 track as well as a two-button switch to activate a belt and eject cans. If you’re using O gauge track, the building will need to be higher, so install the O gauge shim beneath its foundation. Why worry about the height of the building? In order to work right, the loading mechanism must be able to extend into the refrigerator car door. If it is too far from the car, it won’t work, and if it is too high or too low, it may knock the car off the rails. So experiment with the position of the building in relation to the track and freight car before securing it to the benchwork.

To operate the loader, place milk cans on the conveyor belt by the entrance. Turn the controller to “on.” Then press and release the momentary contact switch to cycle the loading mechanism. The car will be loaded one can at a time.

Unlike the milk-car unloader, there is no wireless remote operation of the loader. Also, old magnetic milk cans won’t work with this rig.

The unloader-loader combination was fun to operate, and it jammed or balked no more than a postwar Lionel model does.

Do you want to spruce up your layout operations, and at the same time answer the question “Got milk?” Then check out the operating milk car.