WINNIPEG, Manitoba — A track-repair error led to a rail-joint failure, causing a 2019 derailment of a Canadian National oil train, the Transportation Safety Board of Canada said in its summary of a report released Friday.

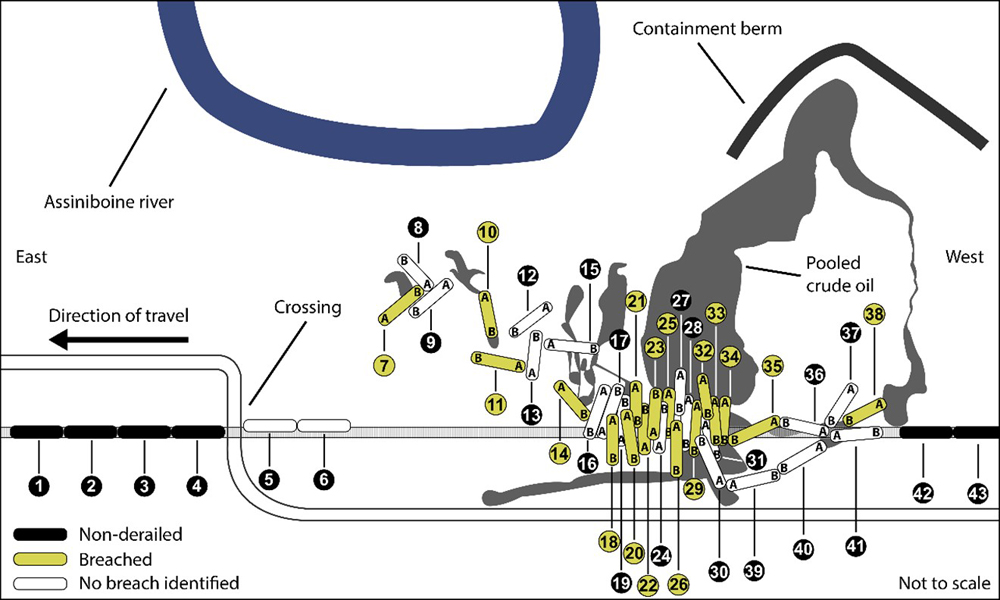

The Feb. 16, 2019, accident near St-Lazare, Man., led to the derailment of 37 cars of a 110-car crude oil train, with 815,000 liters (215,300 gallons) of oil spilling from 17 of the damaged cars. About 1,000 feet of track was damaged or destroyed. There were no injuries and no fire occurred.

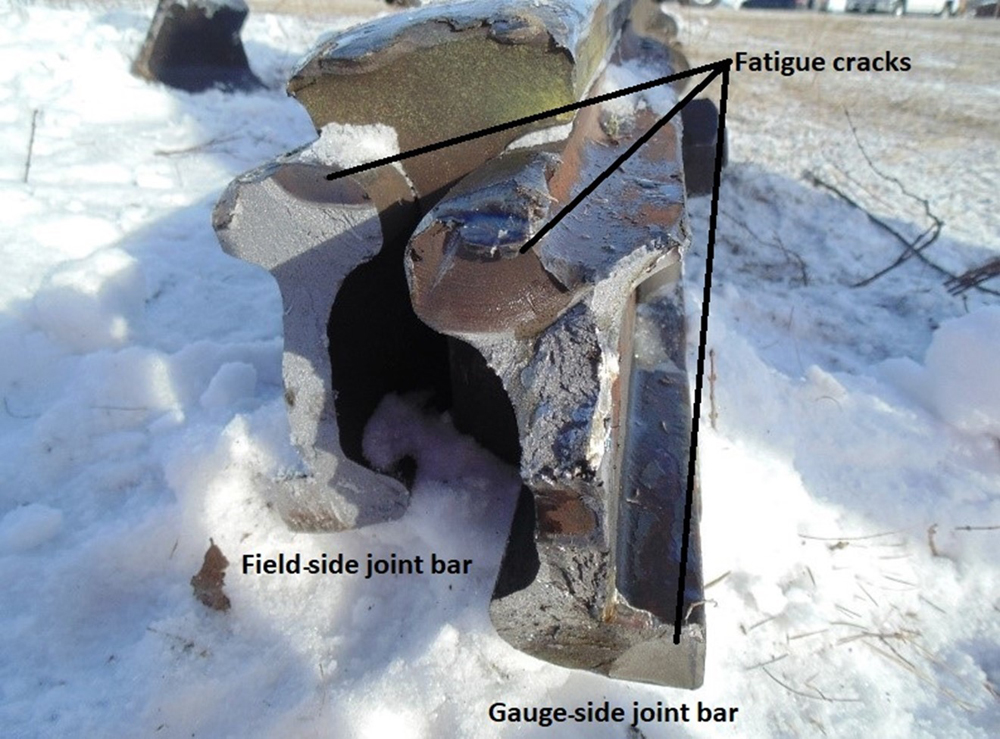

Investigation found that during a repair about six weeks prior to the derailment, a compromise joint bar, used to join rails of two different sizes, was installed along with a standard joint bar. This led to an unstable joint which gradually loosened and eventually failed.

The report notes that the failed joint was one of five in just 49 feet on the track’s south, which affected the stiffness of the track and led the joint to fail more rapidly. The investigation also found a large number of joints and plug rails in the CN Rivers Subdivision, where the accident occurred, indicate deteriorating track structure.

Canadian National subsequently installed 192,867 feet of welded rail on the subdivision, eliminating more than 2,000 joints for temporary plug rails, and now requires compromise joint bars to be painted blue by the supplier to more easily differentiate them from standard joint bars.

Findings address tank-car design, key train rules

The full TSB report also details Transport Canada ‘s assessment of the performance in derailments of the Class 117 tank cars, the newer generation of rolling stock replacing the Class 111 cars which have been prohibited for oil-train use since 2018. The study shows that the Class 117 design “significantly reduces” the potential for release of hazardous materials from the cars’ top fittings and bottom outlets, and that the cars better withstand fires. However, a National Research Council study shows the risk of a car being breached and releasing its contents remains if the train speed is sufficiently high, and the newer design does not reduce the likelihood of a derailment or change the number of cars that derail.

As a result of findings from this derailment and two others involving oil trains, Transport Canada took several actions to revise its rules regarding key trains — those with hazardous materials — and routes for such trains. These included rules announced in April 2020 [see “Canada issues new rules on hazardous material trains …,” Trains News Wire, April 5, 2020]; a November 2020 order restricting speeds in cold weather [see “Digest: Canada revises cold-weather rules …,” Trains News Wire, Nov. 9, 2020]; and additional rule revisions released in February 2021 [see “Digest: Transport Canada issues updated rules …,” News Wire, Feb. 23, 2021].

5 joints in 49 feet. Very bad IMO. Narrow gauge operation not 40 MPH 200k+ # operation. So CN covered its behind by replacing whole sub with welded rail.

Seems like derailments are not incentive enough to drive cash expenditure in infrastructure investment. This “track repair error”, is it an isolated failure to be blamed on one or a few people locally or is it due to decisions made at the top? If CN, the railroad itself, is to blame, perhaps a remedy would be to just take the derailment cost out of the paychecks of the executives? Or, raise the fines to 500 million dollars. Then all of a sudden the cost benefits analysis would dictate we fix our track properly.

An engineer screws up in train handling resulting in a derailment, he’s fired. How is one so simple and the other not?

The type of maintenance defects that were found in this investigation reveal a severe lack of investment in track safety. Plug rails and multiple repair joints are bad news.

I am glad this was resolved. At the time there were a great many protests by First Nations in and around various railroad properties. After CP had a derail of oil nearby a week or two later, a large amount of suspicion was at hand on outside interference. Hopefully the CP investigation will find something similar in their event.