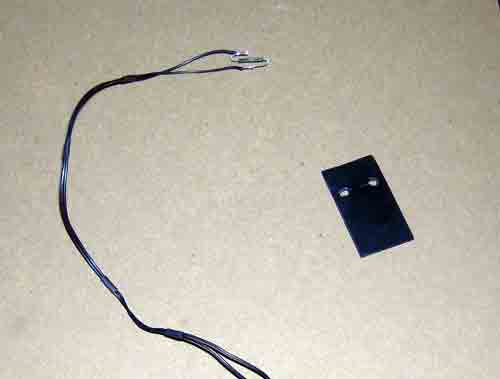

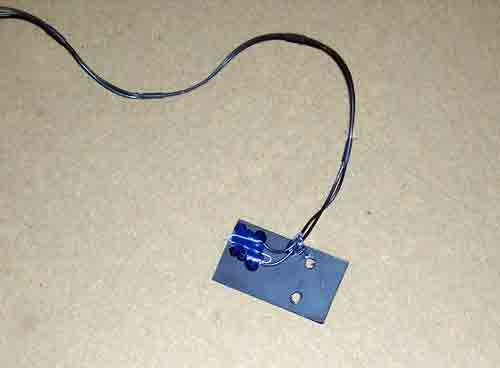

Photo 1 shows the magnets in place (set them where you want them), and the screws pre-threaded into the lower firebox holes provided.

The holes are about .565″ apart, and about 1-1/4″ from the end, and a Number 30 bit.

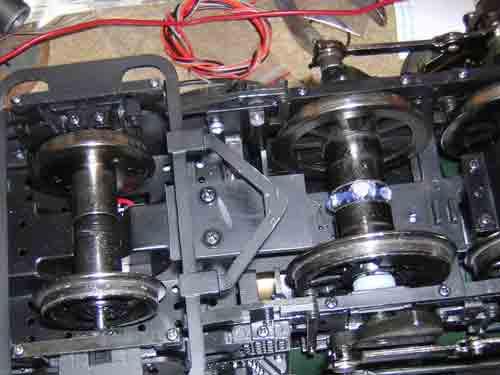

When I saw this unit three weeks ago, I saw the excessive rotational play in the counterweights, plus the wobble.

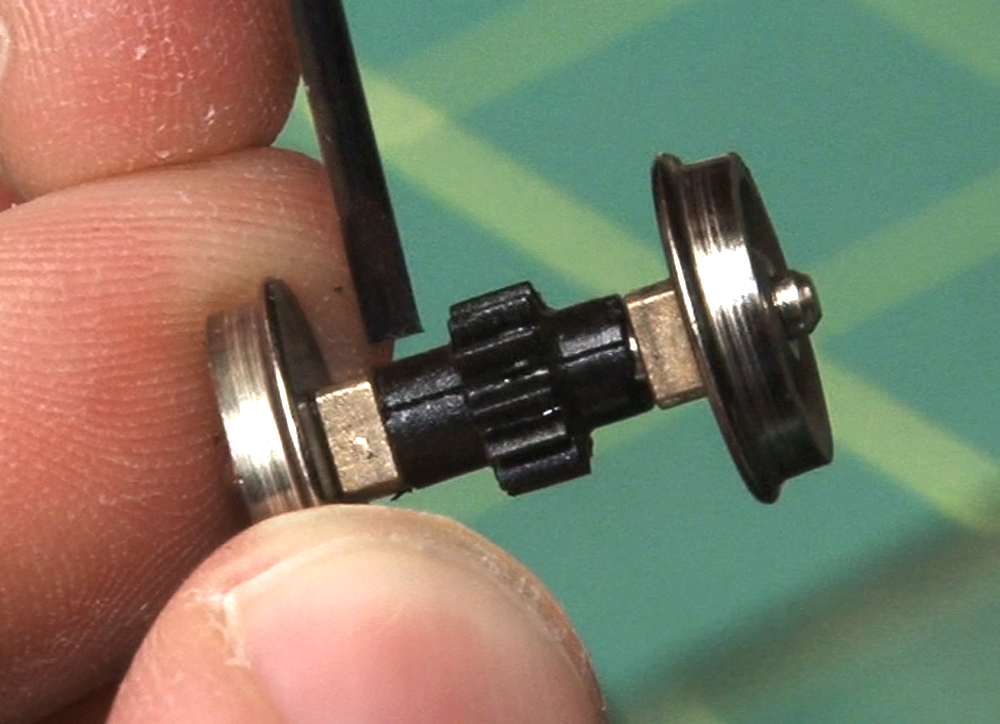

I did some testing of various things to make sure, and the fix was about a .008″ brass shim, .125″ wide, and about .155″ tall, inserted into the space between the axle flat and the counterweight flat.

Prior to doing this, you must remove the counterweight, push the retainer and screw/washers out the front, and test-fit the counterweight to the axle, checking that the axle is BELOW the washer flat inside the counterweight.

You WILL need to file the axle end until it is below this line.

We have now checked numerous units, and have found there is some variation to the thickness required, something we noted to Bachmann on 03JAN08 as a possibility.

Most of the main drive axles, #3, take about a ..006″ shim, and most of those require no filing of the axle end.

A smoothing swipe with a file on the axle flat will allow a .008″ shim insertion.

The tighter the fit, the better!

There was a distinct improvement in operational smoothness once the shims were installed on our unit.

Please do NOT place any load on your locomotive until you have ascertained this problem does not exist on your locomotive.

A posting from the Bach-man on Bachmann’s forum. Please contact Bachmann directly if you are in need of replacement counterweights:

As you know, we have been pursuing the issue of loose counterweights on our new K-27 model. We have ordered new counterweights for all models imported so far, and will suspend shipping of those still in stock untilthe new counterweights arrive. For those of you who already have a K-27, we will advise you through the board when the counterweights arrive, and give you the option of installing them yourself or returning the locomotive to the service department for installation. We will pay the shipping both ways. I received a sample set and was easily able to make the switch in about ten minutes per side. I have posted pictures of the procedure in the gallery. Thanks to all for your patience and understanding, and to the many Large Scalers who helped resolve the issue!

the Bach-man

How do I change my K27 from track power to battery with radio control