Phoenix Sound Systems, Inc.

3514 West Liberty Rd.

Ann Arbor MI 48103

Price: $75

Website: www.phoenixsound.com

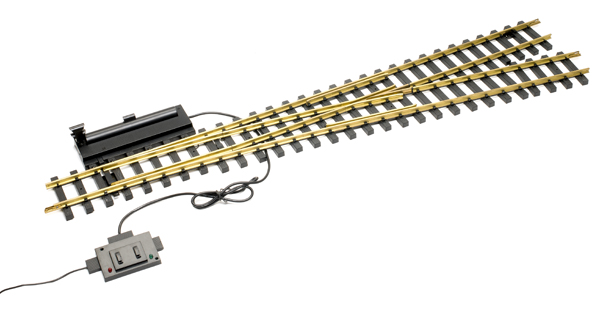

DCC and R/C-compatible control for remote-controlled couplers

Pros: Able to control two couplers independently; controls both servo- and solenoid-based uncouplers

Cons: Programming (fine-tuning) controls via DCC interface only

The board is ideally suited to work with DCC-controlled installations, either “traditional” track-powered DCC or via the DCC output of an Airwire throttle. The board is not exclusively DCC, though. It also has two “trigger” inputs to the board that allow it to be controlled by other R/C systems that have auxiliary-function outputs for triggering sounds or lights, such as the Crest Revolution, RCS, or Railboss systems.

Programming of the board is done via a DCC control system. While that sounds like it might limit the board’s operation for those not running DCC control systems, there’s not a big need for programming if you’re using this in a non-DCC environment. The board’s job is to energize a solenoid on command; you hit the trigger, it energizes the solenoid, and the coupler opens. That changes a little if you are controlling a servo and need to adjust the start and stop positions but the default movement was sufficient to move the servo about 90°. There are plans down the road to allow the user to use Phoenix’s computer interface to be able to program the board, but that aspect is still in development. However, the default settings on the board will likely be fine for most non-DCC applications.

In terms of the parameters you can program into the board via a DCC controller, you can map each of the two independent coupler functions to any of the available DCC functions (1-28). You can also adjust the start and end positions of the servo travel, the speed at which it travels, and the length of time the servo stays open, from 0 to 30 seconds. You can also cause the servo to open, then close automatically—what the instructions call “on-off keying,” where you can use the servo output as an on/off toggle. You can also program the address of the decoder to match that of the locomotive in which it’s installed. Programming is most effective in “service mode.”

Operationally, the board works well. I hooked it up to my DCC command station, set the address to the default “3,” and, with the push of a button, was able to open the coupler. The board has four outputs, tied together in pairs (they call it “A” and “B”).

I found I could connect a servo coupler and solenoid coupler to either the “A” or “B” output, and it would control both of them at the same time. It’s not an “either/or” kind of thing. The outputs are limited to 100mA, though, so if you were to install it so that both outputs were being used, you should be careful not to overload the board. I hooked the servo coupler up to “A” and the solenoid coupler up to “B,” and could control both independently via two different function buttons.

With regard to controlling a servo, I found different servos behaved differently when connected to the board. All of them worked okay but one would stutter a bit when moving while another moved smoothly. I don’t know what the difference might be. Also, sometimes the servo would “chatter” at the end of the throw. Phoenix tells me they’re working to revise the software to allow power to the servo to be cut off at the end of the throw, thus saving power and stopping the chattering, but that’s not yet available.

Hooking the control board up to non-DCC control systems is simple as well. A sample wiring diagram is included in the instruction manual. I hooked my board up to a Crest Revolution receiver per those instructions and had no trouble triggering the couplers.

I am becoming more of a fan of electronics that allow me to do cool stuff, like remote uncoupling. I can easily see where animating your locomotive could become addictive in its own right. The more products that become available to facilitate that, the better, as far as I’m concerned. I think this board will make a welcome addition to that arsenal.