Accucraft

33268 Central Ave.

Union City CA 94587

Price: $1,425

Website: www.accucraft.com

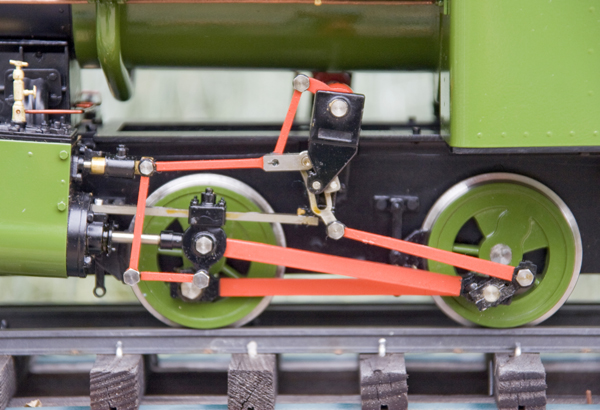

1:13.7 scale, gauge-1 model of a 2′-gauge Bagnall 0-4-0 saddle-tank locomotive; all metal construction; single flue, gas-fired boiler; imitation Walschaerts valve gear; D-valve cylinders; safety valve; pressure gauge; water glass with blowdown; throttle; reversing from the cab; displacement lubricator; link-and-pin couplers; available in black, blue, green, or red. Dimensions: Length over end beams, 111/2″; width, 5″; height, 73/4″. In 7⁄8″ scale, this works out to 13’11/2″ x 5’81/2″ x 8’10”, respectively

Pros: Attractive, well-built locomotive; fully fitted backhead; excellent paint job; excellent running characteristics; captures well the essence of the prototype

Cons: No easy access to the safety valve; non-functional saddle tank; sparse rivet detail; loose smokebox-door latch

Accucraft’s model represents one of the company’s mid-size narrow-gauge 0-4-0 locomotives. The model has a non-functional saddle tank. A filler plug atop the boiler, ahead of the steam dome, allows easy access for filling. Boiler fittings include a 1/2″-diameter pressure gauge, a water glass with a blowdown valve, a throttle, and a safety valve set to 60 psi under a prototypical cover. This cover prevents easy access to the safety valve but it can be removed with a tiny Allen wrench (supplied). There’s a displacement lubricator with a drain on the footplate.

The model’s boiler is the usual single flue, gas-fired job. However, the diameter of the actual boiler is significantly larger than the prototype’s, giving the engine much longer duration. This increase in diameter is somewhat concealed by the saddle tank. A large gas tank resides between the frames; the footplate separates it from the boiler, which should help to keep it cooler. The filler valve is on the floor of the cab, angled about 45° toward the rear. It is accessed through the dummy sliding doors on the back sheet. You’ll need a long stem on your gas filler. The gas valve, disguised as the brake stand on the footplate, is within easy reach and is quite controllable.

The engine has two double acting, D-valve cylinders. These are controlled by dummy Walschaerts valve gear, reversible from a lever on the right side of the cab. Because the cab is so open, everything is easily to hand. The throttle lever is fairly short, being less than 1″ long, and is a little inconvenient. If I were to keep this engine, I would fit a longer one that was more accessible from the side. The tiny 1/2″-diameter pressure gauge faces out to one side. This is an easy fix if you prefer your gauges to face back into the cab.

I have a couple of niggles concerning this engine. While the paint finish is up to Accucraft’s usual high standards, the rivet detail is not. It’s barely discernible on the cab sides, is too small on the smokebox, and is entirely absent from the saddle tank and the roof,. This gives the engine a plain appearance that could easily have been improved with better rivet detail.

I’ve never been a fan of Accucraft’s standard smokebox latch. This is just a small strip of spring stainless steel that allows the smokebox door to snap closed. On our review sample, there’s some slop in the latch, so the smokebox door doesn’t close firmly—it rattles. I tried bending the latch a little, one way and another, but to no avail—it still rattles. I think a better latch could be devised.

Steam-test day was warm and breezy. I filled the boiler via the filler plug behind the dummy saddle tank, about three-quarters full according to the water glass. I was a little skeptical about the angled gas filler, but that proved to be no problem. The fuel tank is large, so took a lot of butane to fill it. I oiled the engine all around with a lightweight machine oil and filled the displacement lubricator on the right side of the cab with steam oil. Lighting up through the smokebox door is straightforward and the fire caught immediately, flashing back into the single flue. Because of the enormous boiler, it took a long time for steam to be raised to 50 psi—more than 15 minutes. When the pressure was up, I turned off the fire and refilled the fuel tank with butane. I then relit the fire and opened the throttle. The engine moved off immediately, with no sputtering, spitting, or hesitation. From that point on it ran beautifully for 45 minutes, at which time it ran out of fuel.

Pressure remained constant at about 50 psi throughout the run, once I had adjusted the fire satisfactorily. The safety valve (set at 60 psi) never lifted. I would like to have seen a larger-diameter water glass, as the one supplied tended to get bubbles and become unreliable. However, briefly opening the blowdown cleared the glass. The reversing lever is on the right side of the cab, next to the boiler. Thanks to the openness of the cab, it is easily accessible. The engine ran as smoothly in reverse as it did forward. The cab is pretty roomy, so fitting radio control would probably present little trouble. At the end of the run I opened the blowdown to relieve the excess pressure, of which there was quite a bit, even though the gauge registered “0.” As an aside, the blowdown could be adapted as a vacuum tap to automatically refill the boiler as it cooled after a run.

This is a lovely engine, both in appearance and performance. It’s nice to have another reliable engine in the 7/8″-scale lineup.