R&G Railroad Company

PO Box 8349

Moreno Valley CA 92552

Prices: See website

Website: www.randgrailroad.com

Wall-mount railroad system; solid oak and oak-plywood conctruction; modular roadbed sections (curves and straights); roadbed sections can be supported by brackes or suspended from brackets or the ceiling; single- and double-track systems available; designed for #1500 curved track (with #1100 on double-track sections); mounting instructions and tool list supplied

Pros: Heavy, solid system; well designed and thought out; can be wall mounted or suspended from ceiling or brackets; well finished, good-looking system

Cons: A fair number of tools and the knowledge and experience to use them are required; website incomplete and not well organized; individual pieces not shown on website

Sent for review were two 48″ straight sections (#OK-ST48, $51.95) and one #1500 90° curved section (#OK-1500, $119.95), as well as a variety of brackets. The system arrived well packaged, with each piece wrapped in plastic and bubble wrap, and the box filled with plastc peanuts. I must note that, due to space and time constraints, I did not actually mount this system on a wall. However, in carefully reading the enclosed instructions, I did not see anything that I felt would be very difficult or out of the ordinary.

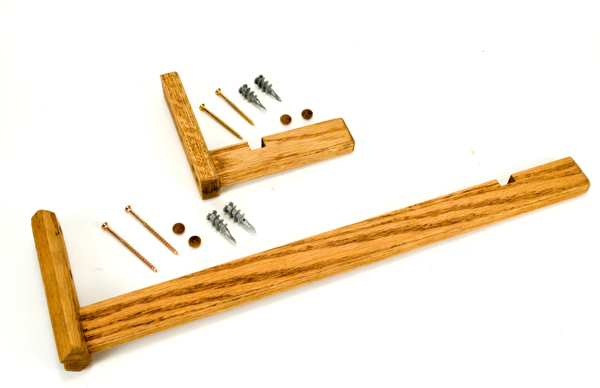

Each roadbed section is made up of three parts. The roadbed itself is made of 1/2″-thick oak plywood. On either side is a 11/8″ x 1/2″ solid-oak trim piece, notched in the middle to accept the plywood section. All wood is finished in hand-rubbed walnut oil. Brackets are in an “L” configuration, each made of two pieces of solid oak, screwed together. The horizontal member of each bracket is notched to accept a trim piece on the roadbed sections.

Special brackets are available for ceiling-mounting the system. We were supplied with #OK/ST-CM/TB ($43.90), for single-track systems. (Double-track brackets are also available.) This consists of two parallel, horizontal oak pieces, separated and held together by 18″ long, threaded brass rods. On the top (ceiling) end, the nuts on the ends of the rods are recessed into the wooden piece. On the bottom (visible) end are brass acorn nuts, a nice touch. The fact that the rods are threaded throughout their length suggests that they could be used for leveling the system. I’m not sure how this would be accomplished, though, as the top nuts would not be accessible once the bracket was in place and the acorn nut at the bottom would limit the amount of thread that could be easily used.

Included with the system was a paper template showing all available modular pieces, drawn at 1″ = 1′ scale. These could be reproduced on a copier and used to design your system over a 1″-scale drawing of the space in which it is intended to go. It would be nice if these templates were available on the company’s website as downloadable PDFs but, if they are, I couldn’t find them. That way, you could design your system and know what parts you’d need to order.

The supplied instructions for mounting the system on the wall were well written and straightforward. However, this is not a snap-togther system. You’ll need a fair number of tools (including a recommended dozen 3″ C-clamps) as well as the knowledge and experience to use them properly. All hardware necessary for installation is provided with each bracket. This includes 21/2″-long wood screws, E-Z Anchors for mounting in drywall with no stud backup, and decorative wooden buttons with which to cover the screw holes in the brackets. The vertical arm of the bracket is intended to point upward from the horizontal arm, so the brackets will not take up wall space below the roadbed.

The instructions tell you how to determine the height of your track and how to establish a level baseline. Special brackets are made for corner installation, which is where you start. As you go along, you install both the brackets and the roadbed pieces, holding everything together with C-clamps and shim pieces. The roadbed sections are not held together mechanically. Brackets must be carefully placed so they will support the ends of both intersecting roadbed pieces.

In the probable event that the system will not fit neatly into your given space, it may be necesssary to trim the last straight pieces to fit. Alternatively, if you want even bracket spacing all along the wall, you may have to trim every piece to achieve equal lengths. This is where pre-planning with the templates comes in handy. Once everything is in place to your satisfaction, the roadbed pieces are to be hot-glued to the brackets.

Once the entire system is up on the wall (or hung from the ceiling, or both), the track can be installed. The instructions suggest screwing the track to the roadbed sections every 18″, as well as on either side of the roadbed joints.

This is a well-thought-out and well-made system. It is nicely finished and should fit in with most decors. While installation will take some work, it should not be difficult to achieve a level and attractive layout. I did find the company’s website to be somewhat disjointed and not that easy to navigate. I think more information, both visual and written, about the products would be a distinct asset, as this is a good product and one that I would recommend to those desiring this type of system.

I would strongly recommend some mechanical fastening of the roadbed sections to each other. This would permit more flexible installation of the wall supports into the wall studs and eliminate the possibility of separations due to humidity changes or flexing as the train moves on the track.