Q: I’m building a new layout using Kato HO scale Unitrack. I have read many different opinions on whether to solder all track joints. What’s the best practice? Some say that using terminal joiners on Kato Unitrack for connection to the DCC bus is OK, while others say they’re unreliable. I use terminal joiners every 3 feet and wonder if I should at least solder those to the rails.

I haven’t seen much about planning for track expansion and contraction. Since Unitrack sections snap together, allowing no gap between rails, I wonder if it would be wise to cut 1/16” gaps in the rails every so often, using my rotary motor tool with a thin circular blade. How often should these gaps be cut? And how do turnouts come into play? – Tom Helm

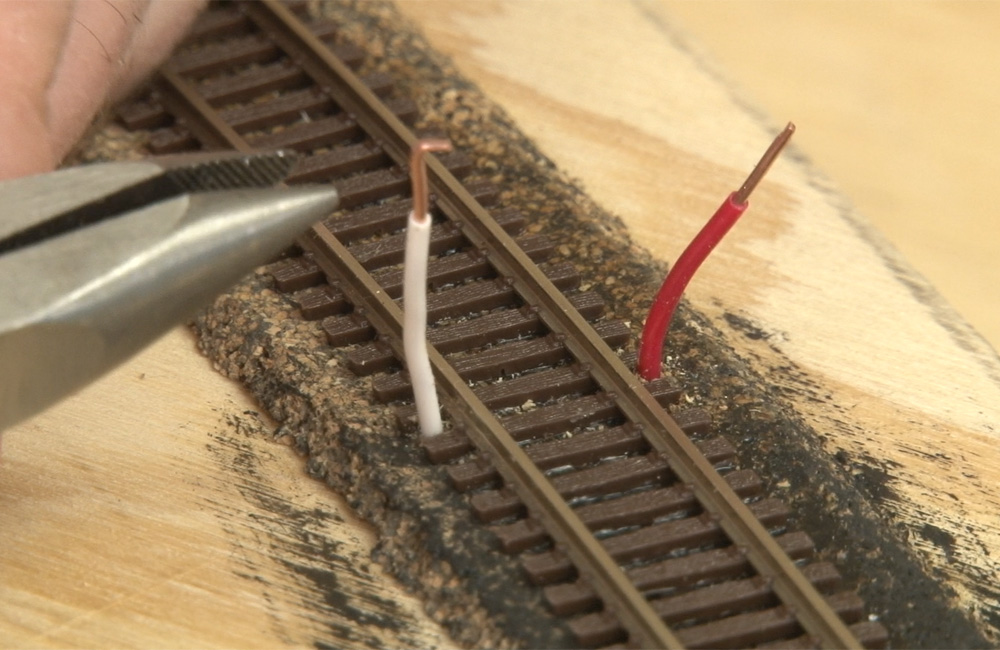

A: It’s quick and convenient to use terminal joiners on Kato Unitrack, especially for temporary layouts that are set up on a tabletop and cleared away later. But if your track is permanently attached to a layout, there’s no reason not to solder feeders directly to the rails. Rail joiners are made of nickel silver, which is not as good of a conductor as copper wire. They can also become loose over time, leading to electrically dead track sections. A better practice is to solder your rail joints (except for insulated joints between wiring districts, of course), and solder track feeders from your bus to the rail every 3-6 feet.

It is generally considered a good idea to cut occasional gaps in your rails to allow for benchwork contraction (which many modelers wrongly attribute to thermal rail expansion). However, sectional track with attached plastic roadbed like Kato Unitrack is less susceptible to this than track that’s attached directly to the roadbed or subroadbed. Plastic roadbed doesn’t shrink over time and insulates the track from the shifting of wooden benchwork. So gapping the track is not as important for you. Again, the exception is for separating wiring districts. Turnouts must be fed power from their point ends, or else short circuits can be created, so rail gaps and/or insulating rail joiners are needed at the frog end.

Another concern is that a rotary motor tool with a cutting disk tends to cut gaps that are wider than desirable. If you must cut rail gaps in sectional track, use a razor saw and be careful to keep the blade steady so the gap is no wider than it needs to be. For more on rail gaps, check out my “Ask MR” answer from July 7, 2022 on Trains.com.

Send us your questions

Have a question about modeling, operation, or prototype railroads? Send it to us at AskTrains@Trains.com. Be sure to put “Ask MR” in the subject.