Do you need some industries for small spaces on your model railroad? If you ask modeler railroaders something they’d like to have more of, space will be a common answer. Everything in our hobby takes up space – benchwork, track, structures, and scenery, among other items. When I kick around layout plans for my basement, I often wish for a few more inches here and a few more feet there. But space doesn’t have to be an impediment to modeling. Here are some clever solutions contributors to Model Railroader have come up with for modeling industries when space is at a premium.

For more industries for small spaces and other space-saving ideas, check out our special issue How To Build More Layout in Less Space. You can order the magazine on the Kalmbach Hobby Store website.

Scrapyard

Scrapyards are great industries for small spaces. In many ways they’re a two-for-one project. You gain a rail-served industry, and you add visual interest to your layout with scrap piles. Bruce Petty took the scrapyard on his HO scale Los Angeles & San Fernando Valley to the next level by using a homemade magnetic loader to fill his gondolas with real pieces of scrap metal.

Among the items Bruce used for scrap metal were rusty tin cans with lithography, ½” steel banding cut into scale 2 x 4-foot sheets, and soft iron wire rolled into coils. He fashioned the loader out of a pocket magnetic pickup tool.

You can read more about Bruce’s compact industry in “Building an operating scrapyard” in the October 2006 issue of Model Railroader.

Modern lumberyard

When you think of a contemporary, rail-served lumberyard, images of multiple buildings spread over a large area probably come to mind. However, Thomas Klimoski effectively modeled a modern lumberyard in a small footprint on his HO scale Georgia Northeastern layout. How did he make it work?

First, he used a low-relief building for the office and indoor storage. Low-relief buildings aren’t a new concept. However, the bump-out with the office that Thomas added to his building breaks up the usual kit-against-the-backdrop look.

What really makes the industry stand out is the effective use of details. Though there are only two car spots, the way Thomas spread details through the scene make the compact lumberyard feel much larger. The details effectively move your eyes through the scene. At first glance you notice the storage racks with wrapped and unwrapped lumber bundles (also notice how not every one is completely filled). Drill in a bit deeper and you see the lumber truck being loaded. Then you spot the two forklifts working the yard, an employee dragging a pallet into the building, and much more.

Thomas’ article “How to model a modern lumberyard” was published in the March 2018 MR.

Oil-recycling plant

During one of contributing editor Pelle Søeborg’s trips to the United States, he was on the lookout for compact, contemporary, rail-served industries. The Safety-Kleen oil-recycling plant in Grand Island, Neb., fit the bill nicely. Even though the prototype is compact, selective compression was still necessary.

The oil-recycling plant consists of three parts: the office/warehouse, storage tanks, and loading platforms. Pelle used a mix of scratchbuilt, kitbashed, and kit-built structures and details to model the compact facility. The prototype receives one or two tank cars at a time, making it ideal for small spaces.

To learn more about Pelle’s project, check out the January 2018 issue of MR.

Corn syrup terminal

This HO scale corn syrup terminal is a backdrop-hugging industry on our Milwaukee, Racine & Troy staff layout. Former executive editor Andy Sperandeo built the terminal using stock and modified commercial kits.

What adds to the play value of this industry is how the tank cars need to be spotted to prevent cross-contamination of the various grades of corn syrup. “Cars will be waybilled not just to the terminal but to a particular spot, and the outwardly identical tankers will have to be switched into spot order before being shoved into the track,” Andy wrote. “Also, as Jim [Lincoln, author of the MRP 2010 article] explained, if any cars already at the terminal aren’t completely empty but have to be moved to spot others, the partially unloaded cars have to be put back exactly where they were. Even though we had room for only a single spur, it’ll give the crew of the Williams Bay Switcher quite a bit to do.”

Open industries

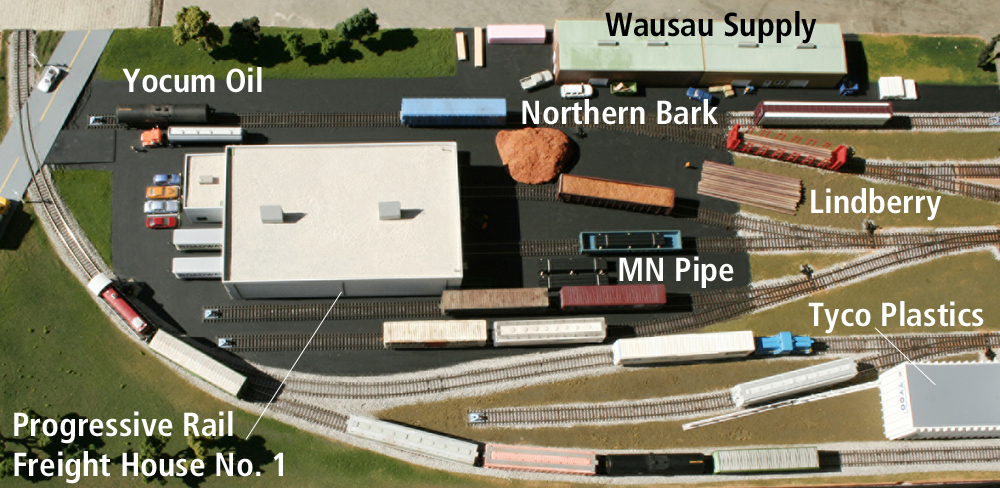

Alan Saatkamp’s 3 x 13-foot HO scale Progressive Rail Airlake Industrial Park layout, featured in the June 2010 MR, included more than a half-dozen rail-served customers with buildings. However, as he explained in the article, a building isn’t a requirement for adding rail-served customers.

Alan added four open industries using existing sidings at the west end of the industrial park. What exactly is an open industry? “My industrial park’s west end features numerous car spots that don’t require their own spur or building,” Alan explained. “The [businesses] have offices nearby but deal in products that are unaffected by the weather.” The four customers that transload from railcars to trucks are Yocum Oil (bulk petroleum products), Minnesota Pipe, Northern Bark, and Lindberry Wood Products (utility poles).