WASHINGTON — The 164th car of a Norfolk Southern train triggered a critical hot box detector alert before a May wreck in Pennsylvania, but the train continued on its journey for 15.34 miles before derailing because neither the crew nor the railroad’s network operations center received the warning that would have required the train to stop immediately, the National Transportation Safety Board said in a preliminary report released today.

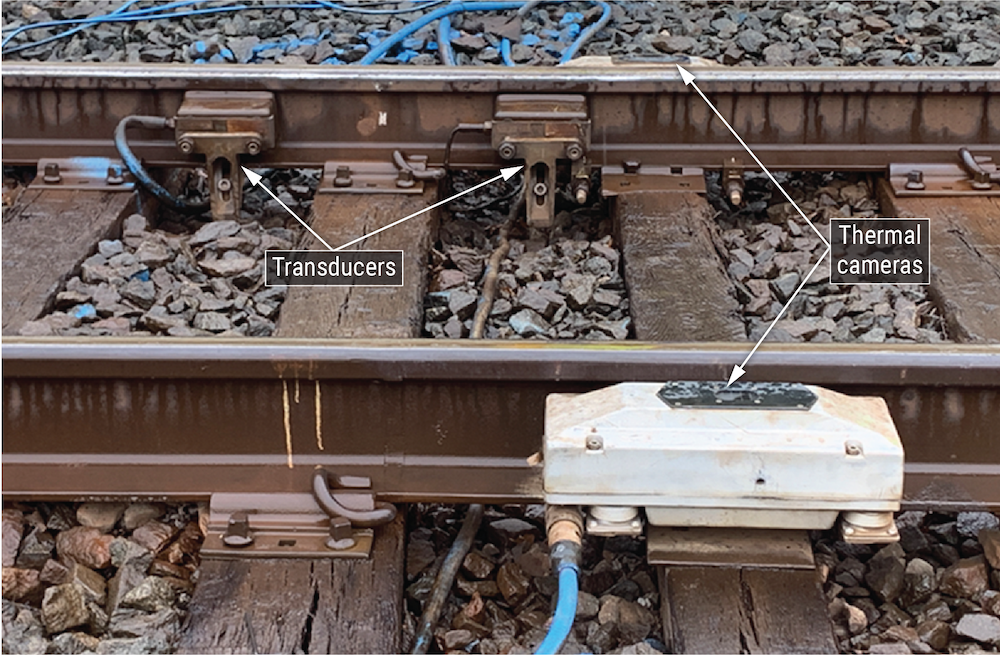

Signal maintainers working in the area two days before the derailment detached and reattached track-mounted hot box detector components, the NTSB said, but the transducers were attached incorrectly and prompted the detector to report reversed train travel directions.

Data logs don’t show that Norfolk Southern’s advanced train control desk in Atlanta received an alert from the detector, the NTSB said. The advanced train control desk requires an accurate report of train travel direction to interpret hot box detector data. “Under NTSB investigators’ direction, signal maintainers corrected the transducers’ positions. In subsequent tests, NS technicians at the ATC desk in Atlanta confirmed that they had received usable HBD data,” the preliminary report said.

“Post-accident examinations did not identify conditions that would have prevented the HBD from transmitting an alarm message,” the NTSB added. “However, NTSB investigators reviewed the inward-facing image recorder and audio data from the head-end locomotive of train 14M and did not find evidence of an audible alarm being broadcast over the locomotive radio.”

Preliminary results of an examination of the locomotive’s radio showed that it was working, but investigators found a loose coaxial connection between the antenna and radio. NS has sent the radio to its shop in Roanoke, Va., for further analysis.

Merchandise train 14M derailed nine cars in New Castle, Pa., at 10:57 p.m. on May 10, some 38 minutes after it passed the wayside detector at milepost 91.9 on the Youngstown Line, the NTSB said. As part of its investigation, the NTSB recovered burned-off bearing components from the 164th car, which derailed along with cars 165 through 172.

The 671st axle on the train was 253 degrees above the ambient temperature, or 53 degrees above the critical alert threshold that requires the crew to stop and inspect the train, the preliminary report said.

The NTSB said its ongoing investigation will focus on the 164th car’s wheelset and bearing, NS’s use of hot box detectors, and NS railcar inspection practices.

The Conway, Pa., to Buffalo, N.Y., train had one head-end locomotive, 144 loaded cars, 69 empties, and two distributed power units positioned midtrain. The 12,724-foot train weighed 19,993 tons.

The train was traveling at 28 mph at the time of the derailment, or 12 mph below the maximum authorized speed of 40 mph. The derailment included one hazardous material tank car that was carrying paraffin, the NTSB said.

No one was injured in the wreck, which came just over three months after the disastrous Feb. 3 derailment of a Norfolk Southern train in East Palestine, Ohio, after the catastrophic failure of a wheel bearing. A hot box detector sounded an alarm moments before the East Palestine derailment, which released hazardous chemicals and prompted an evacuation.

The East Palestine derailment, along with subsequent wrecks, have put the railroad industry under intense scrutiny from lawmakers, regulators, and media. Federal regulation of wayside detectors is among the regulatory changes being considered in Congress.

“Norfolk Southern continues to cooperate with the NTSB’s investigation and our aim is to learn from what occurred and immediately address any issues that are uncovered,” spokesman Tom Crosson says. “We are always striving to be a better and safer railroad. We have already taken several steps to address how we handle alarms sent by our wayside detectors that monitor for elevated temperatures on railcar wheel bearings and alert crews to a potential bearing failure, which could lead to a derailment.”

NS says it has taken action without waiting for the NTSB preliminary report, including:

- Enhancing technology to provide multiple means of communicating temperature alarms.

- Updated systems processes so that wayside alarms are consistently received by the wayside help desk for investigation regardless of their alignment to a specific train.

- Enhanced standards for locomotive radio trouble reports.

- Strengthened the training of standard operating procedures for employees who install and inspect wayside detectors.

NS on March 6 announced a six-point safety plan to enhance the effectiveness of wayside detectors. And last week the railroad announced both the appointment of an outside consultant to lead an independent review of safety practices and a commitment to partner with labor unions to improve safety.

Note: Updated at 4:21 p.m. CDT with Norfolk Southern statement.

This is a case where the technology, for technical reasons, failed to work. The East Palestine wreck is more worrisome. Setting a warning temperature threshold may raise an alarm too late. A better plan might be to place detectors in pairs, perhaps a mile apart. An alarm can then be raised if the temperature is rising too fast.

With trains so absurdly long, not only do many sidings become unusable, if you get a HB warning, how long will it take to go check it out, let alone do something about it? Under PSR, are derailments an expected part of the calculations? Kind of like Precision Scheduled Disasters?

I’m no expert, but for years I’ve seen the hero worship of those corporate bosses who use PSR as an excuse to do a lot of bad things. I’m not impressed. And, keeping Memorial Day in mind, remember that heroes are those put their health and safety and lives on the line to protect others, not those who endanger others in the name of profits or high game scores.

Radio would not receive because of bad coax cable? It would seem that RRs need to place an antenna about 6 – 10 miles from a maintenance location and train make up location. Then a simple call to dispatch or radio maintenance for a radio check would be initiated.

Long trains, topography, other radio traffic. I thought NS was cutting back on excessively long trains.

You mean they did not have a procedure to test that the HB detector worked after theytook it apart and put it back together? In effect, there was no hotbox detector.

As to the chain of communication at East Palestine, there are ways other than notifying HQ 1000 miles away:

1) illuminate a signal in advance of the train identifying the track and showing either “no defects” or identifying the axle(s) with the defects.

2) send a radio broadcast on the frequency used in that territory identifying the detector, the location, either “no defects” or identifying the axle(s) with the defects.

3) both 1 and 2

This tells the guy in the cab with a brakestand and who can stop the train that he has a safety issue requiring train inspection.

All TSA’s on NS broadcast the M.P. location of the detector and “no defects” or any other relevant info over the radio. If the TSA fails to broadcast, the train crew is either required to stop and inspect the train or run at restricted speed to the next one.

Early HBDs had exactly what you mention in #1 above. But alas, they cost money so they had to go.

This info may cause a personal lawsuit against the signal maintainers. Does union have a hold harmless clause in their contract?

Radio traffic can always be stepped on. An expensive solution might have way side warning about 1,2,3, miles beyond detectors to cover various lengths of problem from front.