Digital Command Control, or DCC, is one of two ways most modelers control their trains. Instead of sending current directly to the rails, and making any train that’s receiving that current move, DCC sends packets of information through the rails and to individual locomotives to tell them what to do.

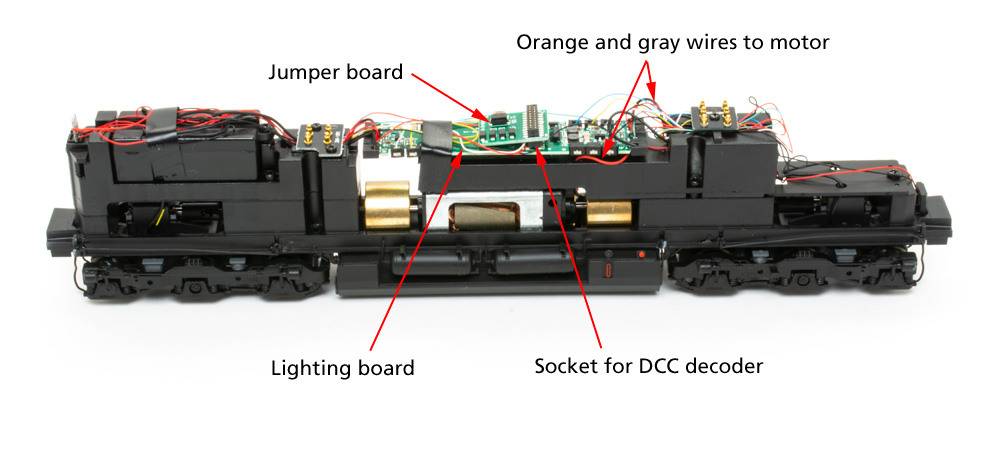

For a DCC system to work properly, you need a command station and at least one locomotive equipped with a DCC decoder. A decoder is the device in the locomotive, connected to all of the locomotive’s main systems, that decodes information sent from the command station and tells each function what to do.

Say you have one or more direct-current locomotives and a power pack, but you want to upgrade to DCC. Why should you do it? Are there reasons why you might not want to? I’ve been through this personally, so let me list some pros and cons when it comes to upgrading from a direct-current system to DCC.

First, the pros:

- With DCC, you have much more control over your trains. You can make multiple locomotives move by themselves, even within the same block. You can create consists with multiple locomotives and speed-match them to run the same. You can even control light and sound functions, if the locomotives are equipped with such features.

- Wiring is much simpler than wiring a direct-current layout with blocks. In fact, a DCC system can be used with an already-wired direct-current layout.

- Many clubs use DCC, so once a locomotive is programmed, it will respond the same no matter what system or layout you’re operating on.

- Manufacturers typically offer locomotives in both DCC and direct-current versions. If you want to buy a new locomotive, you can buy a DCC-equipped unit and run it on your system right out of the box.

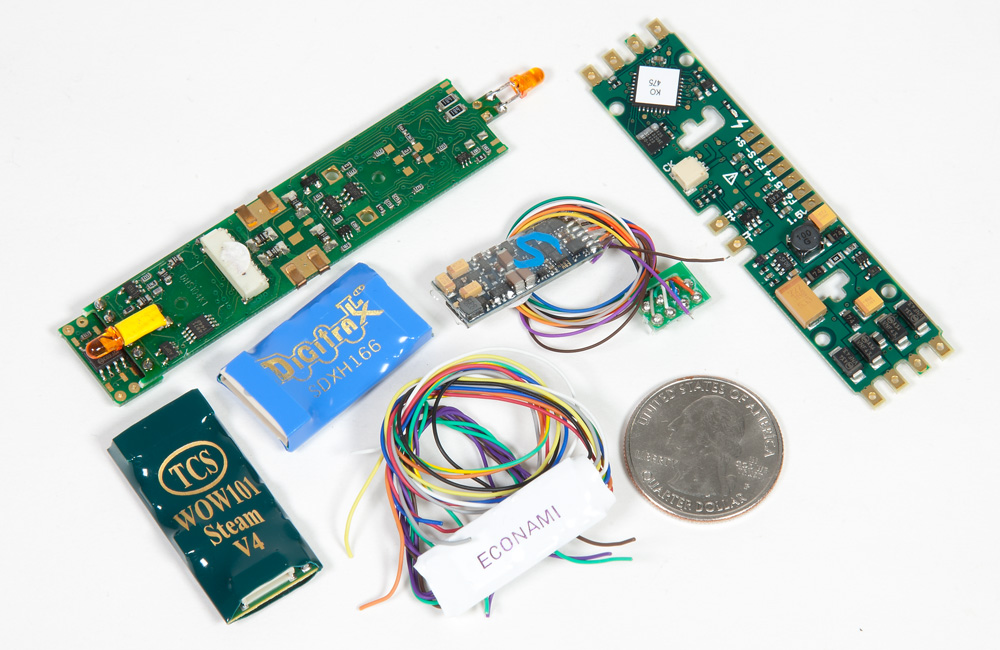

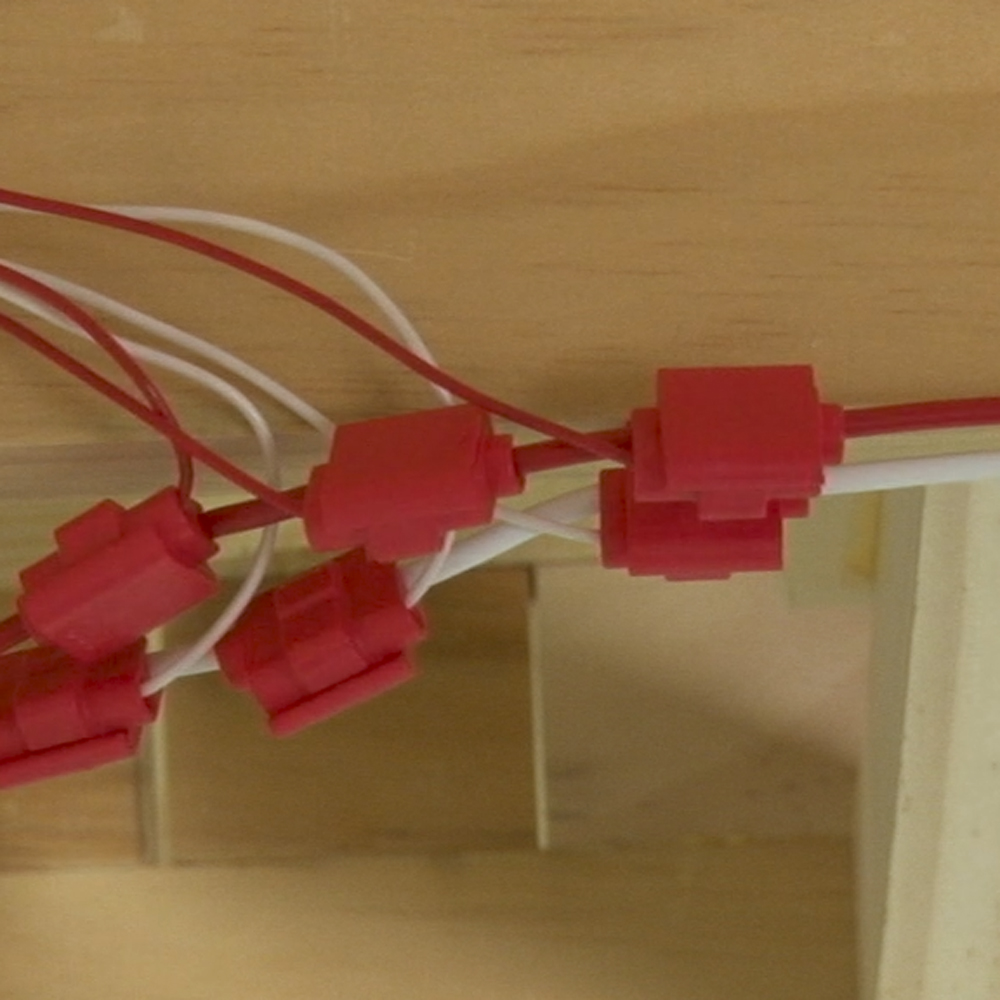

- Many direct-current locomotives produced in the past decade or so include a “dummy” DCC plug in a socket. The socket can be eight, nine, or 21-pin, and you can purchase a plug-in decoder for either of those NMRA standard sockets. This will turn a direct-current locomotive into a DCC-equipped locomotive in just minutes.

- With advances in technology, DCC is always evolving. You can now even install decoders that can be controlled by either a smartphone or a physical throttle.

Now, the cons:

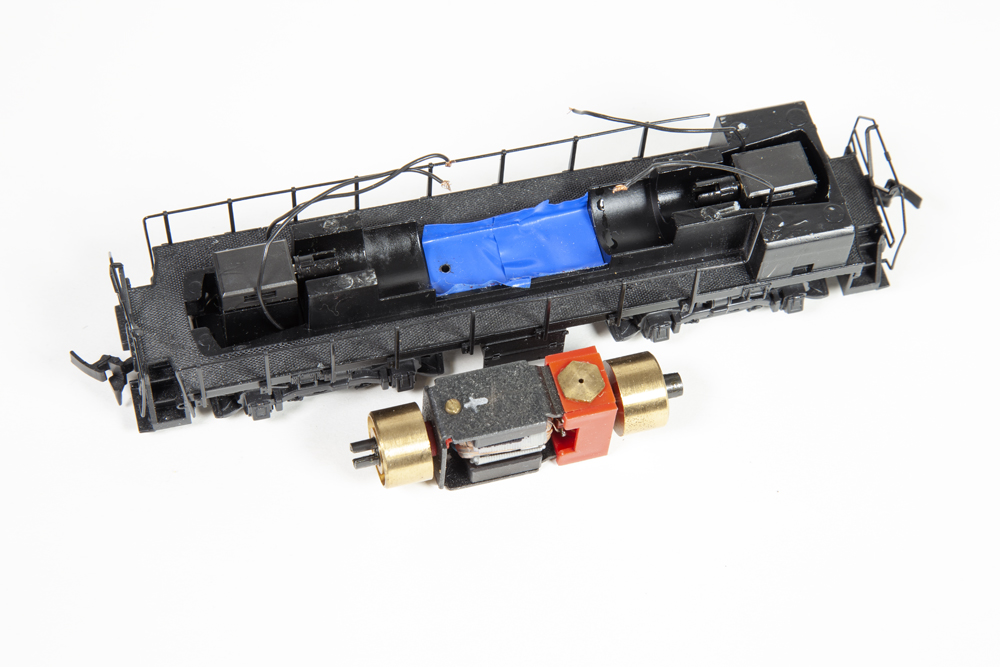

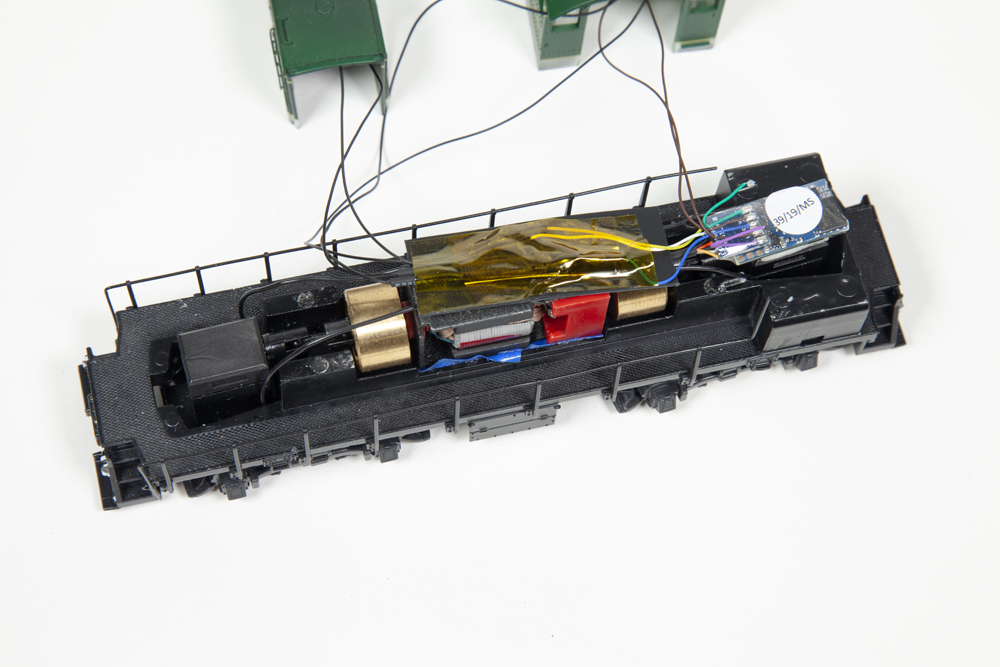

- Soldering. If you want to upgrade to DCC a direct-current locomotive that doesn’t have a decoder socket, you’ll have to solder at least four wires to the DCC decoder; more if you want any lighting or sound function. Learn more about the tools you may need here.

- Time. If you have a lot of locomotives that you want to convert, it will take quite some time to install a decoder into every one. You’ll need to isolate the motor from the frame on older locomotives, solder everything, and test it all. There’s a chance you wired something incorrectly, so the time to troubleshoot and fix increases.

- More money equals more fun, right? Well, such is the case with DCC. A system will set you back around $250 on the lower end. A new locomotive with DCC installed will be at least $100, and that’s on the lower end. And if you’re installing your own decoders, they range in price depending on how much functionality they have. If you want to add a speaker and lights to a locomotive that doesn’t have either, that’s another cost. Plus, once you jump head-first into the DCC world, it opens up opportunities to spend more money!

- Yes, you need space to do installs if you’re doing them yourself, but I’m talking about space in the locomotive itself. If you want to install a speaker, that will require even more space. Some locomotives already have space for a speaker. Some even come with speakers pre-installed. But if not, you’ll have to find or make space. This gets harder the smaller the scales.

Whether you have one direct-current locomotive or 200 to upgrade to DCC, there is a price to pay. After 10 years, I personally thought the investment to switch was worth it. Your mileage may vary. To see what an upgrade to DCC involves for a DC locomotive, check out DCC Projects & Applications Vol.4, available in the Kalmbach Hobby Store.

There are other options. For example, I use the Rail Lynx system to run my trains. It consists a wireless hand throttle (IR transmitter), and a receiver/sensors in the engine. The throttle controls direction, speed, breaking and lights of the loco. I don’t care for the sound features of DCC, so this works great for me. No programming. Just DC power to the track and you’re off and running. It is simple and it work just fine for me.