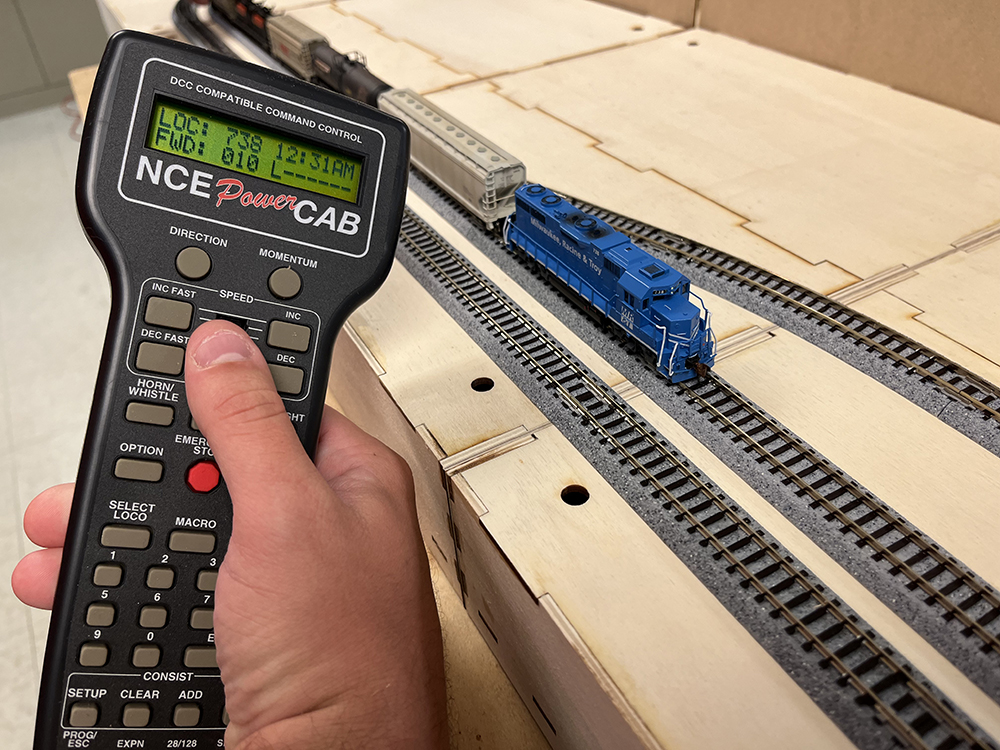

Modelers David Popp, Brian Schmidt, and Bryson Sleppy install the wiring power bus and Digital Command Control system on their modular T-TRAK N scale layout. T-TRAK is a modular N scale railroading system that uses foot-wide boxes plugged together to build tabletop layouts. In this fourth installment, the trio demonstrates how to build a portable wiring bus, as well as how to modify the micro-plywood T-TRAK modules from RS Laser to contain an NCE PowerCab DCC system.

David: The modules are built.

Bryson: The track has been laid down.

Brian: And so now it’s time to work on the scenery!

Bryson: Or do we want to run trains first?

David: I still have to install decoders in my Amtrak locomotives, but I see your point.

Brian: No scenery?

Bryson: I want to run trains. We can start scenery after that.

Brian: That’s ok. I’ve got a bunch of buildings to make first.

David: You’ve got time. It will take us a bit to get the layout set up for operation. Besides, I’ve got a few buildings to make myself.

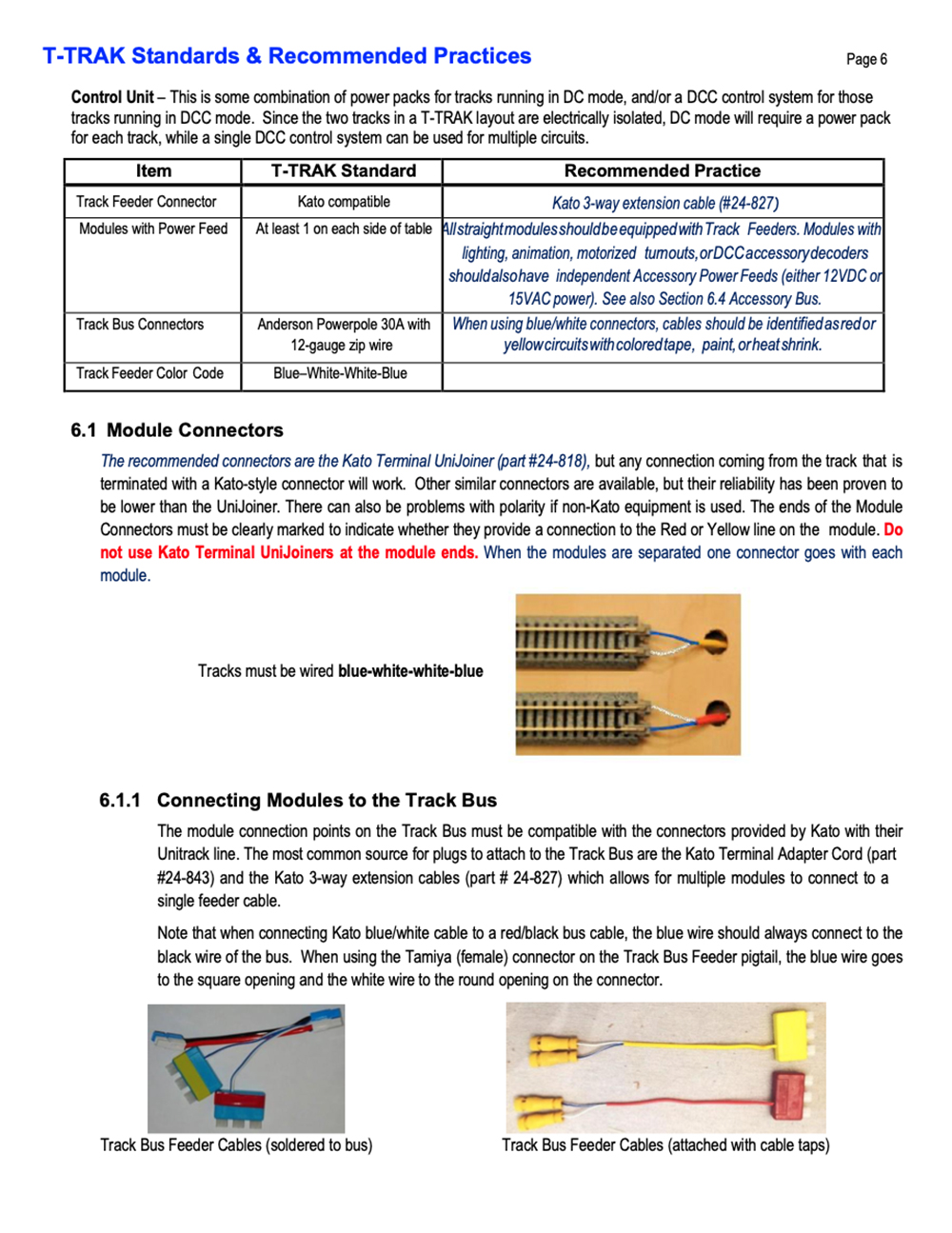

Bryson: Unlike a home layout, where you can wire things anyway you want to, if you want to use your T-TRAK modules with a club, you need to follow the rules. You can find the complete T-TRAK Standards PDF, including wiring instructions, on the ntrak.org website.

David: Yup, that’s the document I used exclusively when writing about T-TRAK for my new N scale book…

Brian: …which will be out next summer – you’ve told us 50 times already!

Bryson: Seriously, Brian? This is only part 4 of our series. Cut him some slack. It’s probably only 42 times by this now.

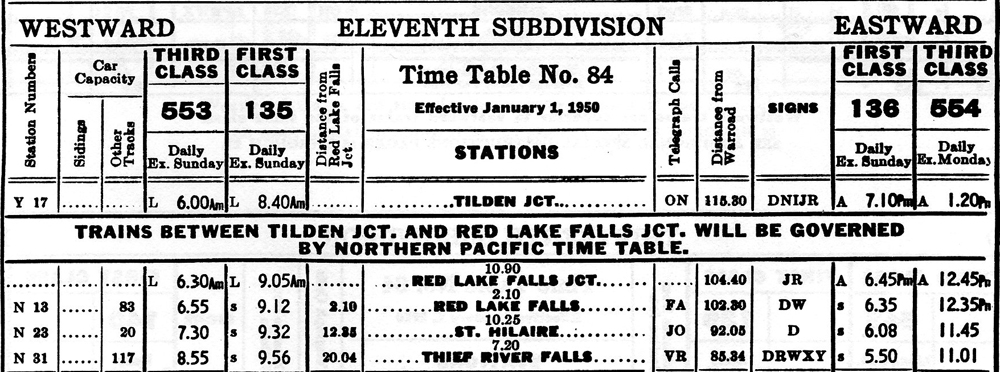

Brian: Like that makes it better. Moving on, in the last installment we discussed how the Kato feeder rail joiners attached to the track on straight modules, as well as the T-TRAK standard that the two main lines are wired in opposite polarity.

Bryson: Blue wire to the outside rail on both lines.

Brian: Yes, if you’ve done it correctly, the white wires should be on the two inner rails.

Bryson: All the feeder components end in standard Kato 2-pin power plugs.

David: That’s were we left off in the last installment. Now we need to connect all those to the DCC power bus.

Brian: I’m assuming there are standards for that as well?

David: Correct.

Bryson: I bet if you’d read David’s book, you’d known the answer to that question.

Brian: Bryson, whose side are you on?

David: Let’s continue, shall we? Because T-TRAK is portable, and most any module can, theoretically plug into any other, the DCC power bus needs to be completely independent of the layout. The bus is designed to sit on the tabletop behind the modules, which connect to it using more Kato power plugs.

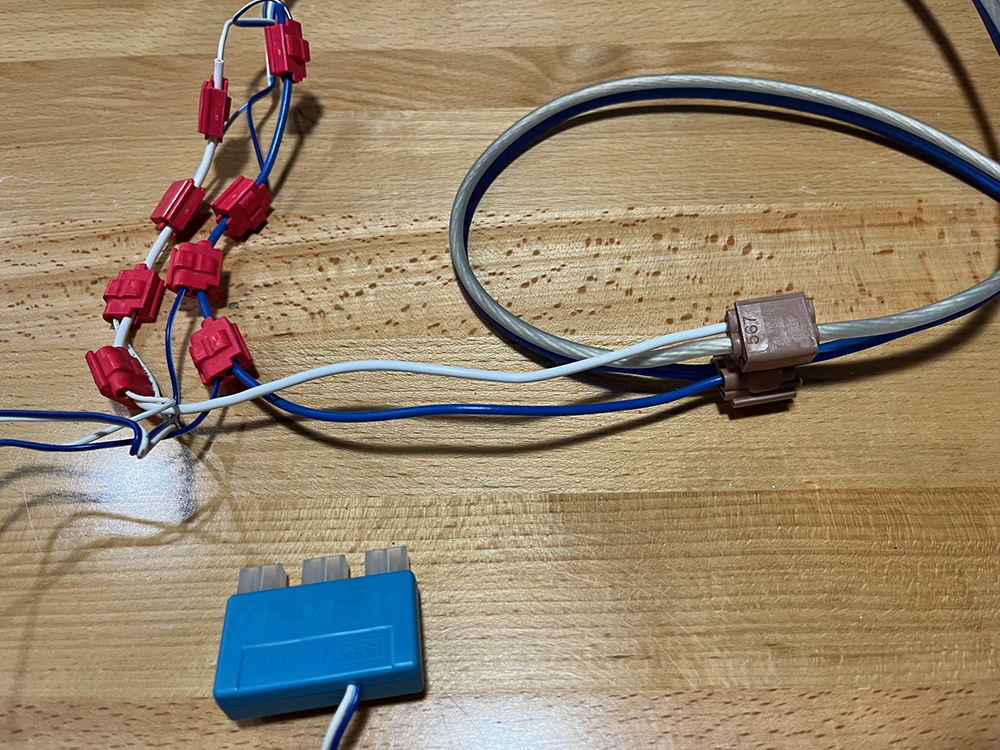

Bryson: Kato makes power extensions with 3-way sockets. It’s item no. 24-827.

Brian: And it offers item 24-825, a single-socket extension, as well.

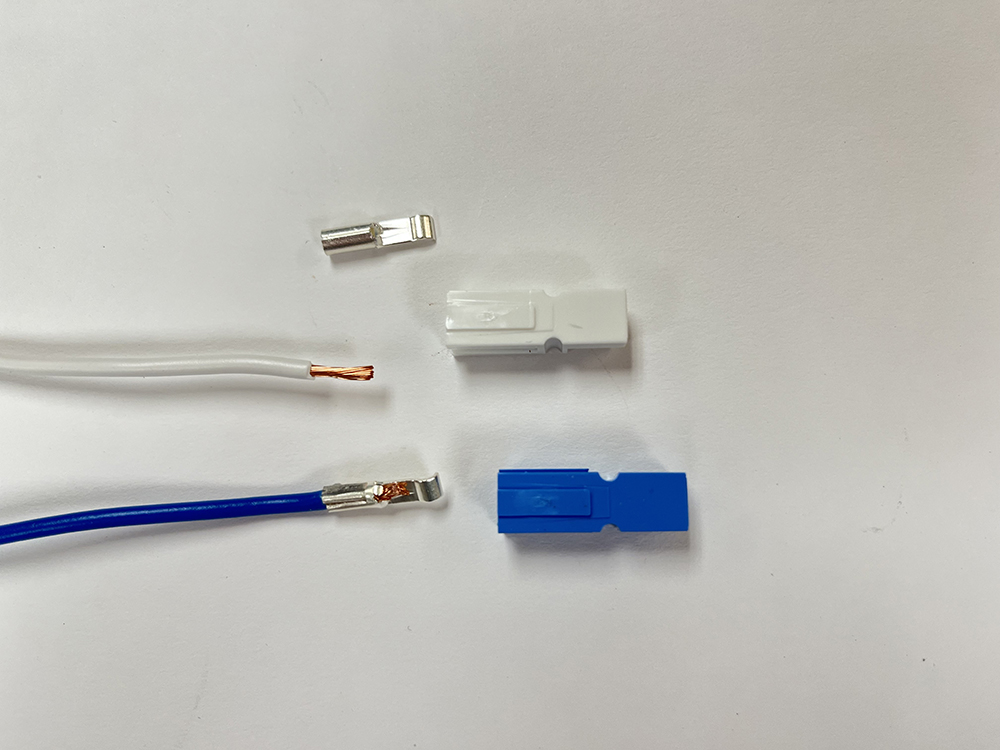

David: Correct, and we will use both of them when making our track bus. The other two things we’ll need are some 12 AWG stranded wire and some color-coded Anderson Powerpole 30A connectors.

Bryson: T-TRAK has a number of different color codes for track power buses, don’t they?

David: Yes, they do, and all that information is found in the standards PDF. Since we are assembling a small T-TRAK layout for our own use, I selected the easiest bus to build. Blue and white wires are used on layouts with a single bus powering both main lines.

Brian: Those Anderson Powerpole connectors are neat, but also kind of expensive. Do you have to use them with T-TRAK?

David: Anderson Powerpole connectors are neat. They are available in colors to match most common wire, and they’re designed to slot together, so you can build custom plugs and sockets. T-TRAK Standard 6.2.3 explains the correct orientation for the Powerpole connectors for each end of the different types of buses, which is used to prevent accidentally crossing polarity when assembling a T-TRAK layout.

Bryson: We used the same connectors on our Free-mo module. They worked well, but you need a special crimping tool you need for them.

David: To attach the metal tabs to the ends of stranded wires, you need a crimper that works with 30A Anderson Powerpole connectors. I got both the connectors and the tool from Amazon. The crimper is about $30, and it really only does one thing – crimp Powerpole connectors, so it is something to consider.

David: To install a connector, strip 3/8” of insulation from the end of the 12-gauge stranded wire. Then slip a metal Powerpole sleeve over the exposed wire and insert both wire and sleeve into the 30A slot in the crimper’s jaw. Clamp the tool shut to crimp the sleeve.

Next, remove the wire from the tool and insert the metal sleeve into the back of the Powerpole socket with the tongue curving downward. Press it in place until you hear it click. Once locked in the socket, the wire cannot be removed.

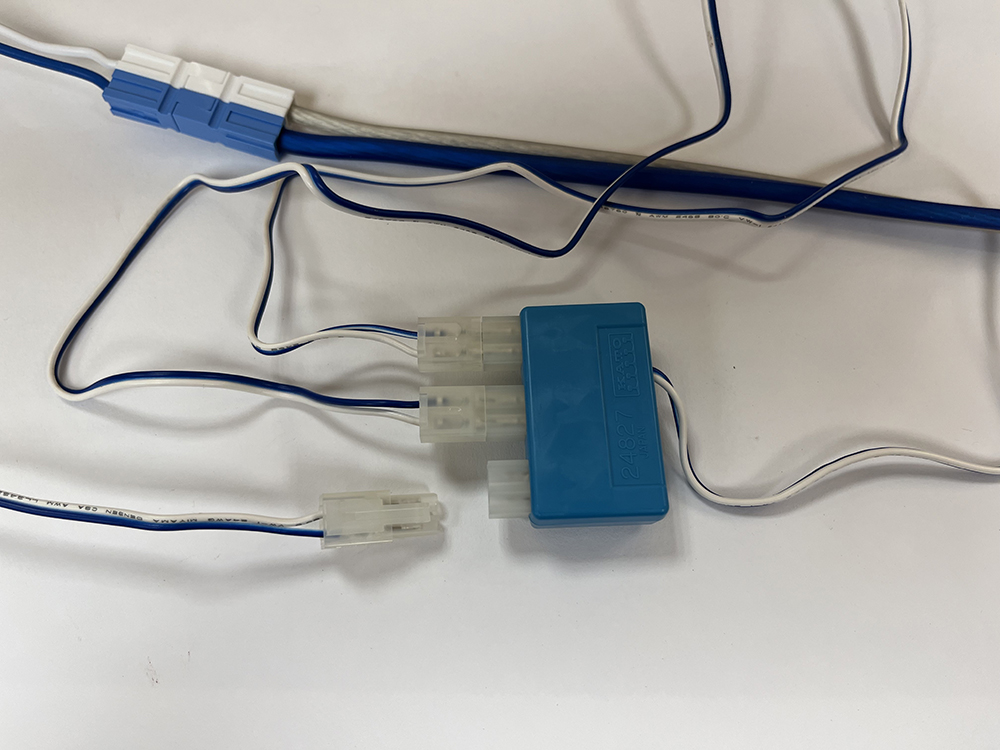

The plastic sockets have locking tabs and grooves on the sides and can be joined with each other in a number of combinations. For our application, the white socket is placed over the top of the blue socket.

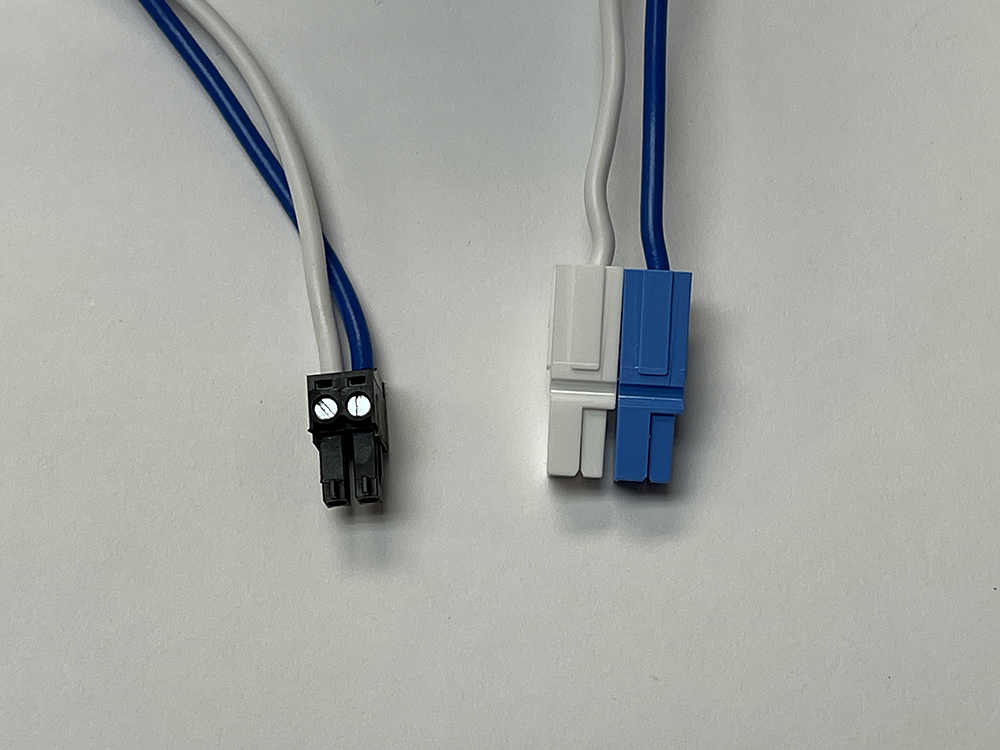

While I was at it, I used a short piece of 16AWG blue and white wire to make a connector for our NCE PowerCab DCC system. On one end I placed Powerpole connectors that will plug into our track bus, and on the other end I installed the black screw terminal that plugs into the DCC system.

Brian: Do you have to use an NCE DCC system to join a T-TRAK club?

David: Not at all. The brand of DCC system is left up to each club. By making a jumper, like we did for our NCE system, you can plug it into any DCC system you wish.

Bryson: Speaking of connections, how do we get the Kato power extension sockets attached to the 12-gauge track bus so we can plug in our modules?

David: Since we built T-TRAK modules with two main lines, I installed Kato extension cables every two feet, pairing up a 24-827 3-way and a 24-825 single giving me the needed four sockets per installation.

Brian: Did you solder the connections to the bus or use suitcase connectors?

David: I used suitcase connectors, but it isn’t as easy as it first appears due to the sizes of the wires involved. 12-gauge wire is very thick, so I needed brown Scotchlok insulation displacement connectors (IDCs) to attach to the bus wire. However, the wire on the Kato power extensions is too small (20-gauge) to be used with the heavier connector, so I had to place 16-gauge pigtail wires between the bus and the sockets, making the connection with the smaller red Scotchlok IDCs.

Bryson: Still beats soldering, doesn’t it.

David: Yes, it does. Trying to strip the insulation from the middle of the 12-gauge bus wires would be tough to make a solder connection.

To use the track power bus, simply lay it behind the T-TRAK modules and plug the feeder wires into the nearest port. The buses are set up in such a way that your bus can plug into those made by others in a club T-TRAK setup.

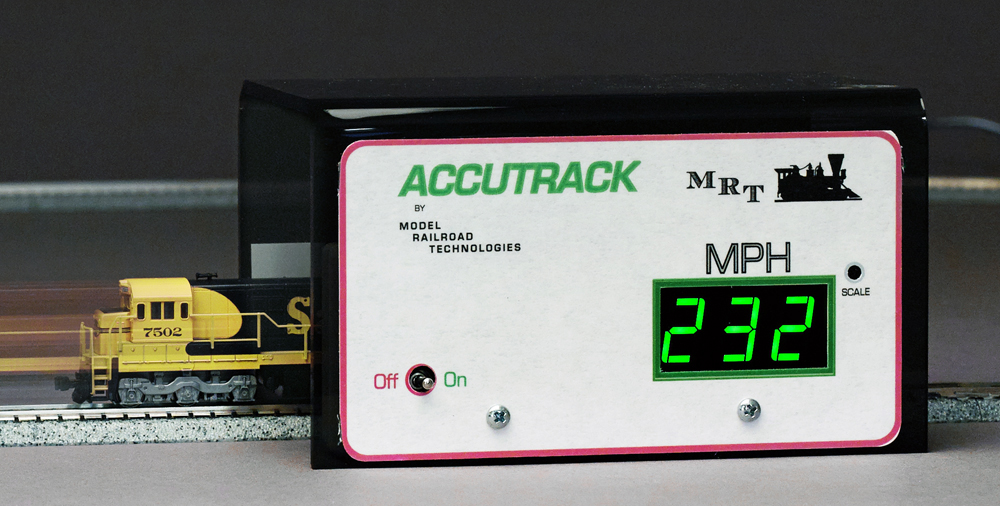

Bryson: Any reason why you chose an NCE PowerCab to run our T-TRAK layout with DCC?

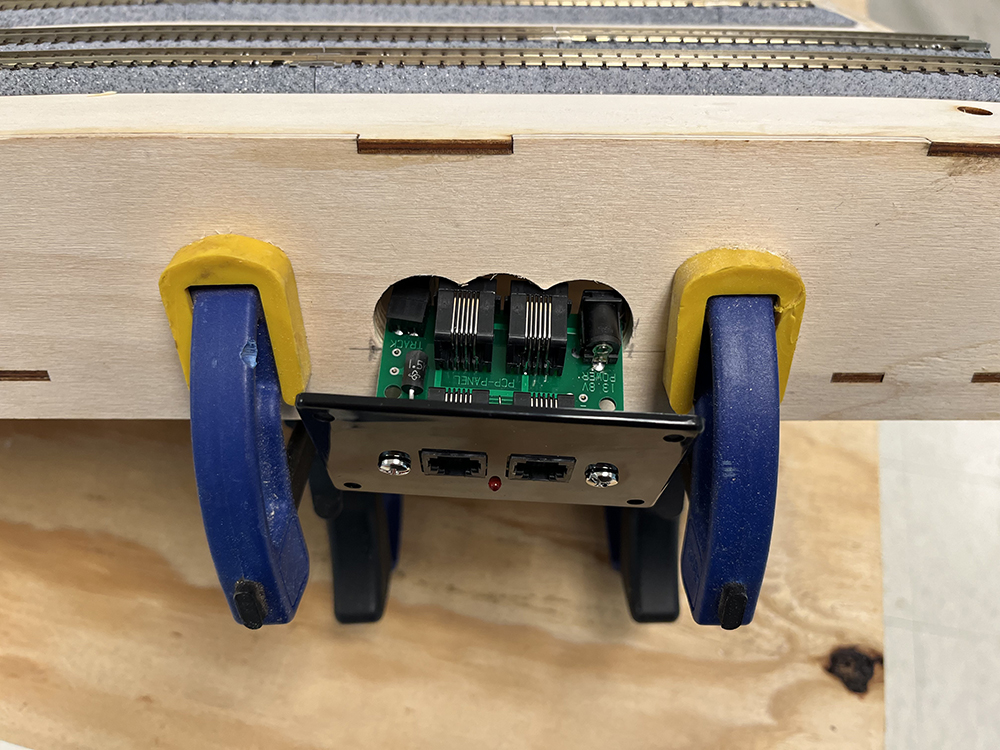

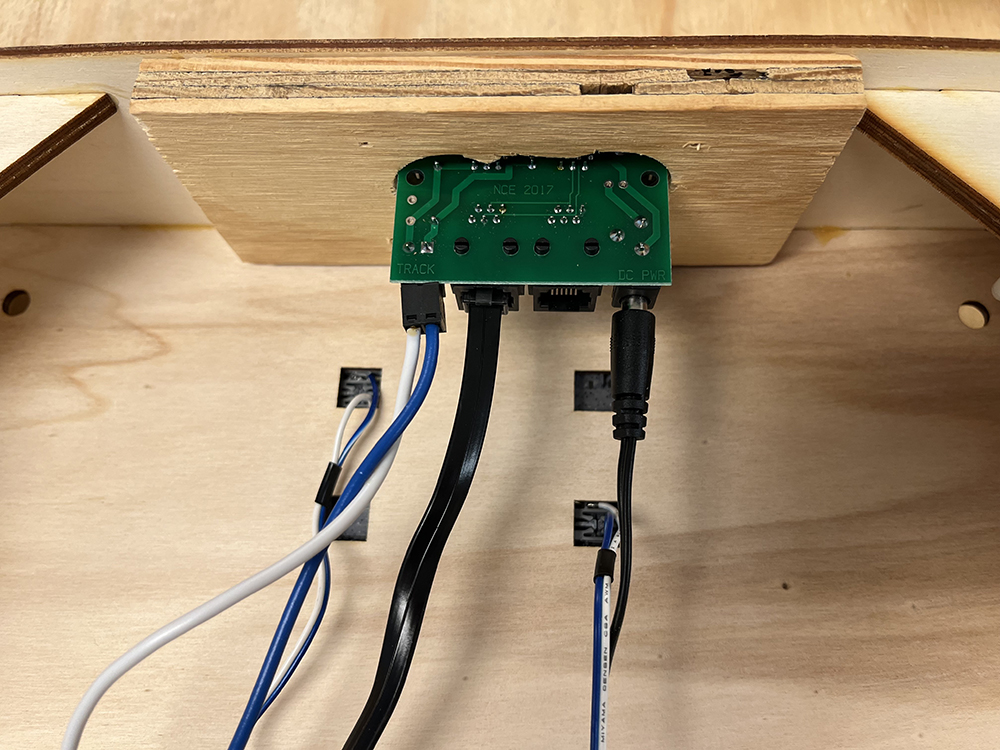

David: First, we had a spare NCE system laying around the shop, so it saved us some money. But more importantly, I really like how the PowerCab system can be installed using a simple plug port as the base station.

Brian: I noticed that you reinforced the thin plywood used on the modules to hold the DCC cab plug ports.

David: I used a small piece of ½” plywood cut to the depth of the module side as a backer for the two plug ports we installed on our T-TRAK layout. I glued it in place with wood glue, then cut out the opening for the NCE panel and installed it with ½” screws. The reinforced front is very strong, so the screws won’t accidentally pull out of the module if someone yanks too hard on the controller’s cord.

Bryson: And the nice thing is that the PowerCab just runs off of a simple wall-wart power supply, so it makes for a clean and compact installation.

David: The power supply and the connection to the track power bus all connect to the one panel. I installed a second panel on the module that will be opposite this one when we set up our loop, so a short cab bus cable is all that is needed to connect the two during set up and we’re in business.

Brian: We covered a lot of stuff in this installment. Too bad I was listening to what you did and didn’t get any of my buildings constructed while you were talking.

Bryson: I’ve got some to build as well, and since we really are starting scenery in the next installment, I guess I need to get going on that.

David: We’ve all got a lot to do yet, but it’s great that we can run trains with DCC now – which means I really do need to get those decoders installed.

Brian: Which means, we’ve got a lot more to come in the next episode of our T-TRAK series!

Bryson: See you there!

Click here to read the next installment of the T-Trak project series!

Click here to read the previous installment of the T-Trak project series!

The Australian guidelines recommend Phono sockets rather than Anderson Powerpoles. Some British groups also use these.