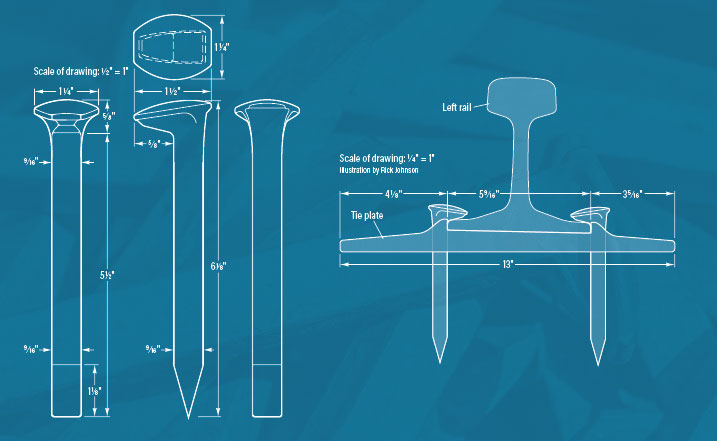

SPIKE dimensions are precise and have been set by such groups as the American Railway Engineering and Maintenance-of-Way Association for decades. Spikes are made of relatively low-carbon steel, which is softer than the steel used in rail and spike mauls. This is important because when a spike is driven, it won’t break into flying steel chips, and it will likely stay in place when bent.

Every lot of new spikes must be tested to see if they’ll perform on the job. To measure this, railroads and spike suppliers can perform metallurgical analysis — to determine proper carbon and alloying element content — and mechanical testing for strength. Mechanical testing requires low-carbon spikes to be bent backward 120 degrees without signs of cracking and stretch at least 25 percent.

Want to find out more about the Transcontinental Railroad?

Facts, figures, history, and more are available from our special Journey to Promontory magazine, available at our partner shop, the Kalmbach Hobby Store.