Microprocessor control

New locomotives have largely included some sort of microprocessor control since the 1980s when EMD’s 60-series line and GE’s Dash 8 line were introduced.

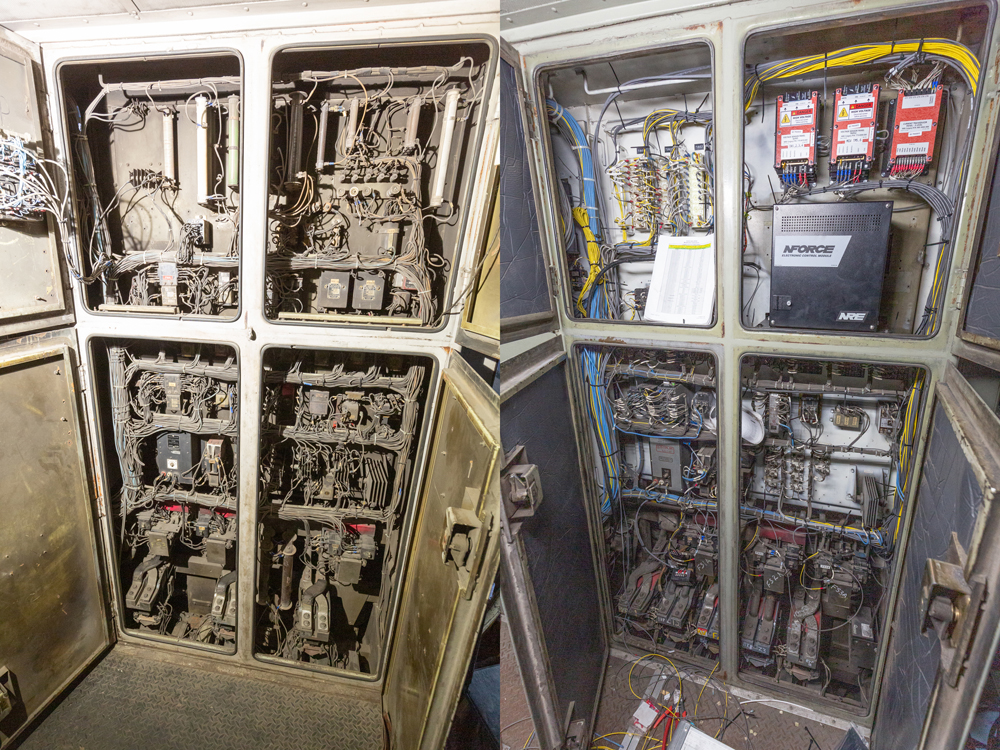

These advanced systems expanded the ability of new power to basically haul more and break down less than older designs. But the thousands of locomotives built prior to this would eventually need upgrades to keep their reliability high enough to justify their continued use. This included a mix of in-kind rebuilding and upgrading older control systems to microprocessor control. Fifty years after the introduction of microprocessors in the electrical cabinet, railroads and third-party companies are still upgrading older locomotive control systems with modern computer systems.

A locomotive control system is the “brain” of the locomotive, accepting input from the locomotive engineer and the environment around it, then applying the necessary changes to the various systems to execute the engineer’s commands effectively. Evolution from relay-based to modular, solid-state components improved locomotives somewhat, but the introduction of the microprocessor control system really allowed manufacturers to greatly expand their products with sophisticated capabilities not possible in older systems.

Microprocessor control allows such things as better wheel-slip detection to improve adhesion, main generator excitation, and fuel efficiency, along with the ability to interface with other systems such as remote monitoring and GPS systems.

Upgraded locomotives may be distinguished by a modified model designation, such as Union Pacific’s addition to “N” on locomotives upgraded with ZTR’s Nexsys control system. An upgraded SD40-2 becomes a SD40N. Other railroads and manufacturers have simply applied a ‘-3’ to the model designation such as a GP40-2 model changed to a GP40-3.

Early upgrades to microprocessor control can often be upgraded to a more advanced microprocessor system down the road, either because the original manufacturer’s equipment is no longer supported, or newer systems have expanded abilities that weren’t present in earlier microprocessor systems.

Manufacturers of aftermarket control systems include ZTR (Nexsys), Medha, NRE (NFORCE), TMV (TECU), and PowerRail (LCC). Progress Rail even sells its EMD EM2000 control system as an upgrade option for older locomotives.

While microprocessor-based control systems can be applied to any type of locomotive, the vast majority in the United States have been used to upgrade older EMD locomotives.

As a great follow-up to this story, how about a picture article showing the revised control and display systems for the engineer in these locos. Do they have new control stands or just mods with updated display screens? Are the engines and generator/alternators also upgraded? What about conversions from DC to AC in many 6-axle GE and EMD units. Lots of possibilities here.

“Manufacturers of aftermarket control systems include Nexsys, Medha, and NRE.”

Nexsys is not a manufacturer. As noted earlier in the article, the Nexsys system is manufactured by ZTR. Another long time and major manufacturer of microprocessor locomotive control systems is TMV Control Systems. And PowerRail just announced their “Locomotive Control Computer”. So the aftermarket control systems list would better read:

ZTR (Nexsys), Medha, NRE (NFORCE), TMV (TECU), and PowerRail (LCC).