BERLIN —The InnoTrans trade fair in late September brought together almost all major manufacturers, large and small, serving the global rail industry. Every InnoTrans edition has one or more overall themes in terms of new technology, and in 2024 the buzz words were AI (Artificial Intelligence) and alternative power sources for trains. In both cases, what was display represented evolution from previous years, but perhaps crucially showed these new technologies are now reality and in use in some countries, rather than just being new ideas at a trade show.

Hydrogen and batteries

Hydrogen continues to be seen as a fuel of the future for the rail industry, with several hydrogen-powered trains on display. Korean manufacturer Hyundai Rotem had brought a hydroge- powered light rail vehicle for the South Korean city of Daejeon all the way to Europe to exhibit it. The Hyundai Rotem vehicle, one of 34 that will be supplied by 2028, uses fuel cells made by its partner company, auto manufacturer Hyundai.

Chinese manufacturer CRRC displayed two cars of a four-car, 125-mph, hydrogen-powered “Cinova” train using hydrogen technology it has developed [see “World largest rail exhibition returns …,” Trains News Wire, Sept. 24, 2024, for an image]. The company also presented plans to build automated refueling robots for use in shops maintaining hydrogen-powered trains. And during the show, Siemens took invited guests on mainline trips on one of its new Mireo +H hydrogen fuel-cell-powered trains; a fleet of these will enter service in the Berlin area in December.

Use of hydrogen and fuel cells to generate electricity to power motors or charge batteries has been around as a concept for nearly a decade — Alstom first demonstrated its iLINT train and exhibited it at Innotrans in 2018. However, fuel cells are not the only way to use hydrogen — it can be burned in internal-combustion engines instead of diesel. Stadler displayed a new regional train, aimed squarely at the German market, called the RS Zero. (The RS stands for Regioshuttle, a long-established name for two-axle diesel trains built by Stadler and widely used on rural lines in Germany and the neighboring Czech Republic.) The RS Zero uses hydrogen and burns it in engines made by German firm Deutz; an alternative, entirely battery-equipped model is also planned.

Wabtec: hydrogen and more

Wabtec officials told Trains News Wire the company is actively testing hydrogen as a fuel for internal-combustion engines with a GEVO engine currently undergoing long-term tests burning a mix of hydrogen and diesel at the Oakridge National Laboratory [see “Wabtec: Hydrogen is the locomotive fuel of the future,” News Wire, Aug. 30, 2023].

Philip Moslener, Wabtec’s corporate vice president for advanced technologies, told News Wire that the company remains convinced of the future importance of hydrogen – but adds that until large-scale green hydrogen (made from electrolysis of water using renewable electricity) becomes available, then alternative lower-carbon alternatives, such as biofuel, may be more effective to reduce diesel consumption.

Moslener also points out that hydrogen fuel cells are a more efficient use of the fuel (compared to burning it), and that the power available from fuel cells is increasing every year, with current models offering nearly twice as much power as those just two years ago. However, he sees the move to using hydrogen as a long-term transition, and steps along the way to reduce fuel usage, as well as introducing alternate fuels to reduce diesel use, are all part of the future. Moslener says he can see advantages in using engines that can burn either hydrogen or diesel; in states such as Texas or California, where hydrogen is likely to be plentiful within a decade, the locomotives can use that fuel, but switch back to diesel elsewhere.

Wabtec also displayed a new modification for existing GEVO engines to use exhaust gases in the engine’s turbo to generate electricity,. effectively adding a generator within the engine. This can then be used to power one of a unit’s six traction motors, effectively reducing the need for full power from the engine and therefore fuel consumption. The company has also previously invested in battery technology and is building the first full-scale 7 megawatt-hour battery road locomotives for Australian mining firms and some smaller 2.4-MWh switchers for use in New York City.

Caterpillar-owned Progress Rail also had a big stand at the show, and was exhibiting the Caterpillar-made lithium-ion batteries with which it is now equipping its “Joule” line of locomotives; the company’s display featured images of a battery-equipped, rebuilt SD40 (an SD40JR), using a pantograph fitted just for recharging.

Rare look at work in progress

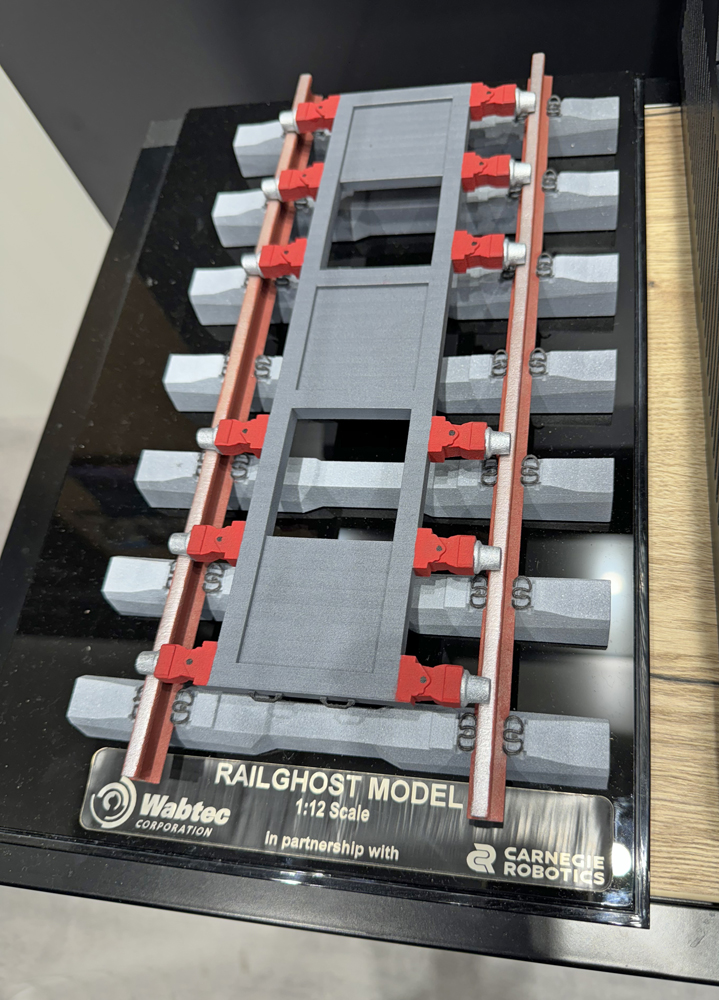

Wabtec had a variety of “work in progress” projects on display from its Advanced Technology Group team, which the company describes as its version of the Lockheed Martin “Skunk Works” approach. As most rail manufacturers rarely show anything in public that has not gone through extensive testing, the Wabtec approach is refreshing, as the company freely admits some of the ideas may not come to anything — and certainly not in their current experimental form. Some of the highlights of this display, as shown to News Wire in a tour, include:

— A “robotic sled” called Rail Ghost — a wheeled trolley with flexible wheel supports that can go underneath a freight train, going around the cars’ wheelsets while keeping some wheels on the rails, and automatically check car status and look for axle defects — was on display in model form, although a video showed the prototype in testing. Another concept displayed was an effort to remove the need for air supply for train brakes; the “airless” electro-mechanical brakes envisioned would not need an air supply or fluids.

— While artificial intelligence and machine learning was a recurring show theme, Wabtec had a practical and focused example it calls “one bot.” The concept is that the bot can be trained on full technical manuals and drawings, enabling engineers to much more easily find relevant information than by looking through a multi-thousand-page manual. Wabtec stresses that the bot must only be trained on official documentation and not other sources — for example the internet. If kept secure, it will provide only original manufacturer information.

— Wider-scale use of “tele operators” to drive trains remotely or assist onboard crews in finding defects is also being examined. Wabtec sees industry interest in this, as it could aid recruitment, potentially allowing some work currently done outdoors in all types of weather to be done remotely.

— Intriguingly, Wabtec displayed models of a possible future autonomous switching locomotive. This is perhaps not that unusual, as robotic switchers are already in use inside equipment-shop yards in some European countries. But Wabtec has short line use in mind for its locomotive, and has even built a prototype powered by batteries (although diesel and hydrogen could also be used in a future production model). This is being tested at a Wabtec facility, as shown in a video at InnoTrans and in an image supplied to News Wire, although the display model of future “Maverick” locomotives is rather more stylish. Two versions of the locomotive are envisioned — the “Maverick” is a new build (although the prototype uses a three-axle truck from an older locomotive), while the “Pathfinder” concept would use existing locomotives but equip them for autonomous operation with new digital equipment and sensors.

AI and real-time sensors

Many manufacturers are now offering a variety of sensors and trackside monitoring equipment that enable railroads to identify problems before they cause damage or derailments. Progress Rail and Wabtec both had displays showing their latest systems – in both cases, the software linking the monitoring devices and the data from them increasingly use AI to predict problems based on previous data. Wabtec says its research shows around 50% of freight car maintenance costs relate to wheels and bearings – and that acoustic sensors can spot defects long before they become critical; linked to AI-driven software, this can prioritize cars for inspection and repair. Progress Rail was exhibiting its “Talos” train automation system, which the firm is developing to create a train driving/fuel management system based upon machine learning from previous journeys.

A French consortium including rail freight company Europorte (owned by Channel Tunnel operator Getlink), France-based satellite operator Kinéis and Internet of Things (IoT) specialist Kerlink, plus French software firm Synox launched a new freight car tracking and condition monitoring system called “Track Value.” This not only has sensors but also has computers onboard every car. The small rectangular box, in a module connected to the sensors fitted on the car by Bluetooth, is about 8 inches long and weighs around 0.75 pounds. It is designed to be used for five years before it needs replacing (the battery life drives the unit life). The system is being offered to rail freight companies for around $300 a module per year and is already in use with Europorte in France. This is similar to North America’s RailPulse, whose backers include four Class I railroads, Railroad Development Corporation, GATX, and Greenbriar. This provides a platform for real-time information on car status, location, and condition, using GPS and either new or existing sensors on freight cars.

— Updated Oct. 13 at 12 p.m. to correct and amend details on Track Value tracking system.