ATLANTA — Carload traffic has increased 62% at a Chicago transload center that Norfolk Southern acquired a year ago.

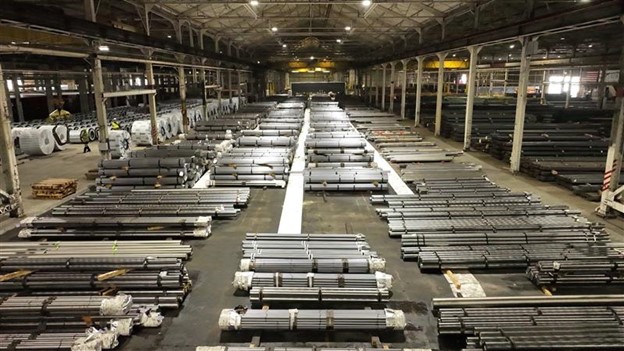

The Great Lakes Reload facility handles inbound loads of steel, cement, lumber, and other bulk commodities.

“Transloading bridges the gap for businesses that aren’t directly connected to rail,” Stefan Loeb, vice president of business development and first and final mile markets at Norfolk Southern, said in a statement. “Our investment in the Great Lakes Reload facility is part of our commitment to providing flexible, customer-focused solutions.”

The 60-acre GLR site has an outdoor rail capacity of 175 cars, a climate-controlled 386,000-square-foot warehouse with 13 overhead cranes, 18 indoor rail spots, and indoor box car docks. GLR operates the facility and support operations for Norfolk Southern.

“Transloading allows businesses to scale their supply chains quickly,” said Chuck Marias, a spokesman for Great Lakes Reload. “With Norfolk Southern’s support, we’ve seen rising demand for these solutions. Companies want to cut costs and improve logistics, and transloading delivers on both.”

NS said it acquired the facility in April 2024 to advance its strategy to convert so-called flexible freight to rail. Flexible freight can move via truck or rail — or in this case, both.

Makes sense since modern freight railroads don’t like switching into industrial sidings. so bring it in to a central location and let the business pick it up from the transload.