Expect to see UP begin running longer trains this year — and building the extended sidings to necessary to handle them.

“We want to build the length of the trains up…” Vena told analysts on the railroad’s fourth-quarter earnings call on Thursday morning. “We might have to target some places where we can meet larger trains and that’s what we’re doing to do. And we want to do that fairly quickly.”

UP is studying where to extend sidings and will fund the projects by shifting money around in this year’s $3.2 billion capital budget, says Tom Lischer, executive vice president of operations.

Running longer trains — which reduces train starts and locomotive and crew requirements — is a key element of the Precision Scheduled Railroading operating model UP began implementing in October.

UP is already building longer trains by blending unit-train traffic into its manifest network and, in certain instances, combining trains that run between the same pair of terminals.

Vena, who was CN’s chief operating officer under then-CEO E. Hunter Harrison and was hired to oversee PSR implementation at UP, said he likes what he sees at UP so far.

“It’s a great company, great franchise, and great people. It really has,” Vena says. “We’re going to put some extra focus on operating efficiency. UP was already started doing that before I showed up, which is nice.”

Vena says he doesn’t see any major differences between CN and UP regarding implementing PSR.

“We’re going to do it as quickly as possible,” Vena says. What takes the longest, he adds, is getting people to think differently.

UP may be thinking differently about hump yards.

When UP announced its shift to a PSR-based operating plan in September, executives initially said they didn’t expect to close hump yards, as Harrison did while leading CN, Canadian Pacific, and CSX Transportation.

But Vena says everything is under review.

“Everything’s on the table,” Vena says, noting that he visited one of UP’s humps last week. “There’s no ifs, ands, or buts that we have opportunity. So everything: Flat yards, hump yards — there is nothing that’s not on the table. And I’d be remiss to say listen, we’re going to shut X amount of yards with 10 days on the job. But we’re going to spend a lot of time to make sure we have the plant set up to handle the business as efficiently as possible with great service.”

In November, Fritz said UP’s 14 classification yards are all operating above 80 percent of fluid capacity and that it would continue building its 15th hump, the $550 million Brazos Yard in Hearne, Texas, that’s due to open late this year.

But if transportation plan changes did drop a hump yard below the 80-percent figure, Fritz said then the yard would wind up in the terminal review process.

UP executives said they were pleased with progress the railroad was making on its Unified Plan 2020.

“Since starting this initiative in October, we have improved on-time service for our customers while at the same time eliminating excess costs and improving the utilization of network resources,” Fritz says.

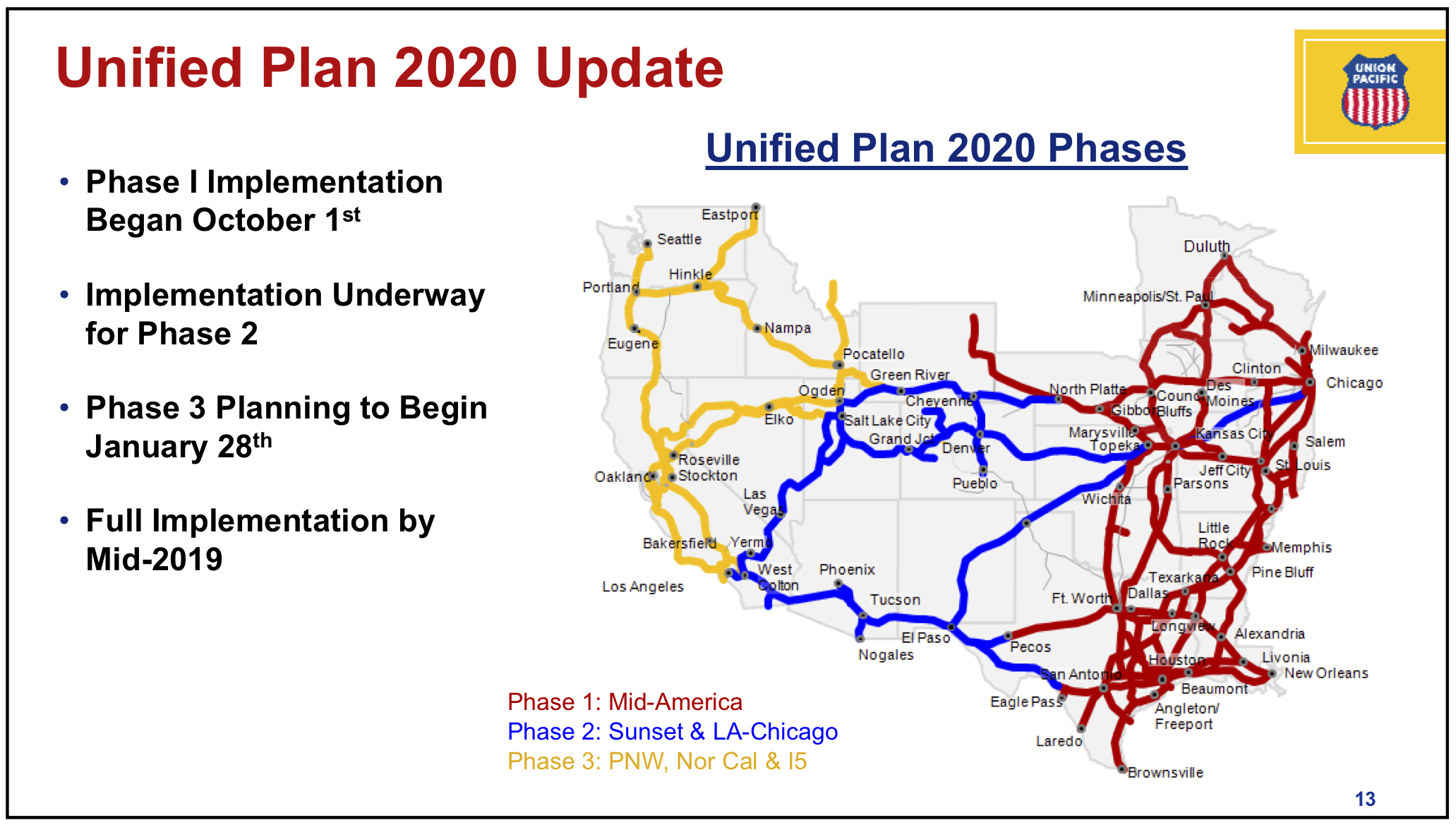

UP will begin implementing the third and final phase of its new operating plan on Jan. 28 on its routes in the Pacific Northwest, Northern California, and the Interstate 5 Corridor. The railroad aims to have the Unified Plan 2020 fully implemented by midyear, which is about six months ahead of the original projected schedule.

UP first rolled out its PSR-based operating plan on Oct. 1 in Mid-America Corridor routes linking the Midwest, Chicago, the Gulf Coast, and Mexico. The second phase, which began late last year, includes routes linking Los Angeles with Chicago and Texas.

Executives said UP was getting good traction from the new operating plan, as cars moved faster, spent less time in yards, and the number of cars online continued to decline even as the railroad hauled more freight.

Compared to September 2018, car trip-plan compliance is up 14 points, to 75 percent, roughly in line with UP’s target.

Locomotive productivity is up nearly 7 percent and the number of cars online dropped 14 percent despite volume increasing 3 percent. For the fourth quarter, average terminal dwell time dropped by 18 percent. Average train speed, however, decreased by 3 percent.

The operational improvements have allowed UP to store 1,200 locomotives since August. The total size of the active fleet is down about 2,000 units since peaking amid congestion last year.

One analyst asked whether a faster pace of operational changes would result in service disruptions.

“I’m sure you can find some number of customers at UP who can tell you they’re not really happy because we fundamentally changed our service product,” Fritz says. “Broadly speaking, the network is providing a better service product to most of our customers and that’s our intent.”

UP has experienced a 35-percent reduction in service issues on its manifest network in areas where the new operating plan is in place, Lischer says.

This PSR to me is wasting time and money ,case in point the railex produce facility in Rotterdam industrial park,before the m/t reefer cars 50-100 at a clip would leave the facility pulled by U P engines right back to Walla Walla Washington State directly express style . Now the m/t reefers are put on a siding track and sit for a couple of days to be taken to the Selkirk yard I believe to lash up with other freight going west. Now crews have to handle these cars twice or three times more then just once when they would leave the Railex facility the way it started in the beginning , this is more labor intence and time consuming . By the time they are ready to head back west now then the old way, they would be back in the state of Washington already by a day or two.

Wow! What a load of corporate double-speak. Although it might be interesting to hear “the rest of the story”, such as what the non-cherry-picked quoted companies are saying about service.

Looks like the cancer called PSR has infected the UP!