When I was in high school in the late ’90s, I saw a TV show that ran a segment on the emerging technology of 3-D printing. Immediately, I thought about how useful those machines would someday be for model railroading.

I kept an eye open for the day when 3-D printing, or rapid prototyping, would finally become good enough, cheap enough, and user-friendly enough to use for my own model railroading. Then, in 2011, I learned about a service offered by a relatively new company at the time called Shapeways.Shapeways is a 3-D printing company that allows people to upload and buy their own 3-D printed designs.

Shapeways also allows individuals to open stores to let their designs be printed by others for a designer-selected royalty.

There are other 3-D printing companies out there, but I’ve used Shapeways, so I’m going to focus on my experiences using its services.

Design

If you browse Shapeways’ website, www.shapeways.com, you’ll find many model railroad products available for sale. But if you want something not yet available, you’ll have to either design it yourself or hire someone to do it for you.

I will say that designing a 3-D model requires ample computer confidence, and the investment of a lot of time for learning. Not only do you have to learn how to use 3-D modeling software, but you also have to learn the design rules to make a design printable. Inevitably, 3-D design software will become more user friendly.

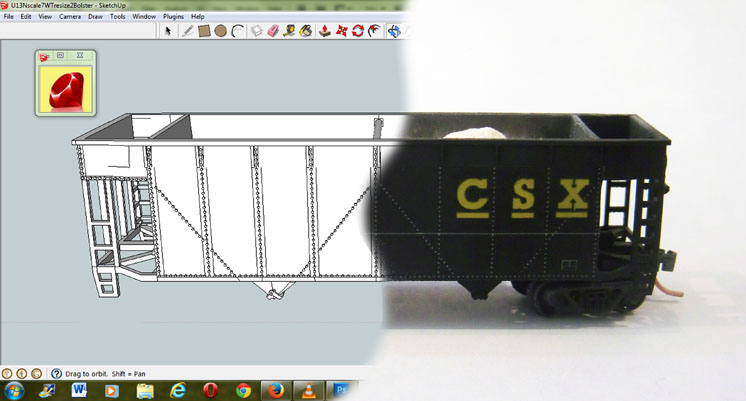

There are a number of 3-D design programs available for free online, such as Blender and Sketchup Make. Make is the free version of Sketchup. There’s also a version called Sketchup Pro, but it costs a few hundred dollars. I found Sketchup to be the easiest to learn. The main downside to Sketchup is that it isn’t good for designing organic shapes. But since most of the things model railroaders want to design aren’t organic shapes, Sketchup is fine. There are numerous tutorials on YouTube to get started with Sketchup.

Sketchup has a few finicky qualities that require workarounds, though. For one, you’ll want to work 10 times larger than the actual size of the model you are making. Sketchup doesn’t handle small dimensions well. If you work in millimeters, working 10 times larger is relatively simple. Also, for a design to be printable, it has to be what is called “watertight.” In other words, the model can’t have holes in it that make the printer unable to differentiate between what needs to be printed and what doesn’t.

Accutrans 3D software, which is free to try and inexpensive to own, solves both problems for PC users, but isn’t available for Mac. Before you use it, you’ll want to install a free plugin in Sketchup called “SKP to DXF or STL.” That allows you to save your model from Sketchup to an .STL file, the file type the printer prefers.

Open the .STL file in Accutrans 3D and you’ll be able to check if it’s watertight. The software will show, in red and green, problems with the model. You’ll have to go back and fix those in Sketchup and repeat the watertight check process until the model is deemed watertight. Once watertight, you “save with options” the .STL file in Accutrans 3D with Output Scale Factor (OSF) set to .1 size, to make up for working 10 times larger in Sketchup, and your model will be print-ready at the right size.

As long as you designed your model within the guidelines for the material you want your model printed in, your file will be ready to print.

Fig. 4 Material options. A sample of Shapeways materials (from left) stainless steel, White Strong Flexible plastic, Black Detail plastic, White Detail plastic, colored sandstone, alumide, and Transparent Detail plastic, are in a holder made of White Strong Flexible and Black Strong Flexible plastic.

Frosted Ultra Detail: $3.49/cubic centimeter + $5.00 setup fee

White Strong Flexible: $1.40/cubic centimeter + $1.50 setup fee

Materials

There are different types of 3-D printers, and the different types of printers are fit for printing different materials, sizes, and levels of detail. In general, the cost of printing depends on the material used and the amount of material needed to print. For that reason, bigger scales mean bigger costs when it comes to 3-D printing. N scale and Z scale are the most cost-friendly.

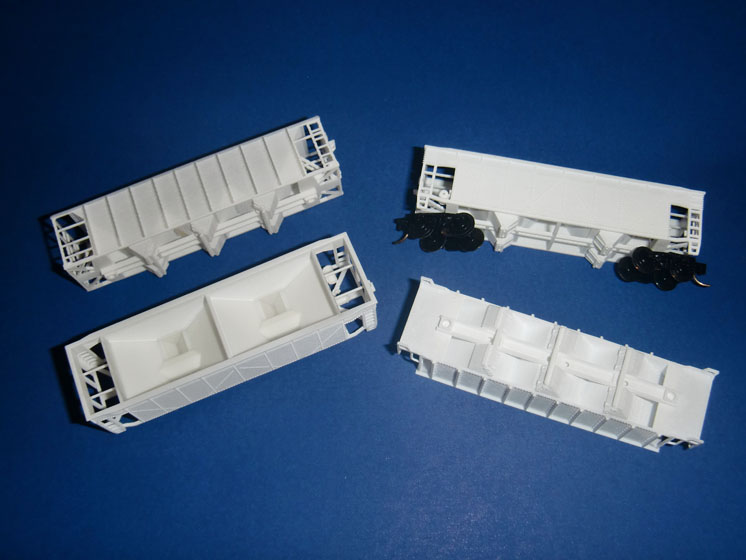

I like a material Shapeways offers called Frosted Ultra Detail (FUD). The material provides great detail at an affordable price. Frosted Ultra Detail is a translucent white plastic, but brittle compared to the plastics commonly used in models. The maximum size of a model printed in FUD is 184 x 284 x 203 mm (length x width x height), or about 71⁄4 x 113⁄16 x 8 inches. I’ve used FUD to produce many N scale freight cars, seen in figs. 1 and 2, at about $15 to $25 per car, and I’m happy with the results.

Although FUD can produce great details, there’s still a fair amount of inconsistency in the printing process. A lot depends on how the model is oriented during printing. As a result, sometimes the 3-D printer spits out a wonderfully detailed and smooth model, and other times (most often) the model requires a bit of delicate sanding to smooth the printing ridges.

There are materials available from printers other than Shapeways that can produce smoother, higher-detailed models than FUD, but the price of those materials is much higher.

Frosted Ultra Detail models come with a waxy residue on them left over from the printing process. To remove it, I use Bestine. Also known as heptane, it’s used for thinning rubber cement and can be bought at craft stores such as Michaels, Jo-Ann Fabric, A.C. Moore, or Hobby Lobby.

I use a glass jar with a lid and pour in enough Bestine to cover the model. I let the model soak overnight with the lid tightly sealed, because Bestine will quickly evaporate. You can save and reuse Bestine many times. Soaking the model also changes the color of the plastic from translucent to a nice opaque white, a great surface for painting.

Another useful 3-D print material offered by Shapeways is called White Strong Flexible (WSF). It’s very strong, but not as detailed or smooth as FUD. White Strong Flexible has a bit of a grain to it that can’t be easily sanded away. Shapeways offers a polished version of WSF for a bit more money, but the polishing process changes the final size of the model.

I used WSF to make a model of the Palm River Bridge in Tampa, Fla. (see fig. 3.) The model bridge is so strong I could stand on it. And since the bridge was printed with precision, everything is perfectly square.

The 3-D print materials I’ve used the most are FUD and WSF, but there are many other materials available (see fig. 4). For example, you can print in sandstone, stainless steel, and a variety of plastics that offer varying degrees of strength, detail, and cost. Sandstone and WSF are the only material available from Shapeways in a range of colors.

Modeling the future

3-D printing appears poised to become a ubiquitous part of model railroading. Other than the easy precision and unlimited reproducibility, the best part of modeling using a computer is that in virtual space there is a handy feature called “undo.”

I can envision model railroading becoming more popular than ever thanks to 3-D printing. For one, 3-D printing makes model railroading a potential creative outlet for tech-savvy youth. Moreover, 3-D printing has the potential to make amazingly detailed modeling available to everyone regardless of skill, money, time, or space.

Alex Marchand is a writer, artist, and private investor. Alex models the phosphate mining region of Central Florida known as the Bone Valley. For more information on Alex’s 3-D modeling, go to his Bone Valley Modeler website at www.theuniverseas.com/bvmodels/

+ 1 for sketchup. Made a BN/BNSF well car with the free version. Also, for detailed prints at low prices, there is always resin 3d printers. The Anycubic Photon is currently around $230. Very affordable.

Anybody knows under which brand-name I could get heptane in Canada ? I live in the Montreal area and Bestine is not distributed here .

Thanks

Hello I have been working with 3D printing at Shapeways and I also use the FUD (Frosted Ultra Detailed material) and fine it the best for the scale I'm in. I do "Z" scale 1:220 The FUD material Does show better details when printing and I think that the home version printer seem not to do the greatest in detailing. the cost is by volume of material used so the bigger the model the more the cost. Then there are some size rules for support wires for the material used and Fud again can be used for smaller support wires. Cleaning the wax and oil use for support and cleaning. I fine that bestine is the best along with Dawn dish soap and hot water to remove wax in tight places. No spaces on the model should be completely inclosed because the wax will remain inside. all inclosed spaces must have a excape hole . But the best thing in the process is doing the 3D drawing then is having it printed then the real model in your hand! really amazing!

https://www.shapeways.com/shops/walts-trainz-and-things-z?sort=newest

I wanted to somehow scratchbuild a specific turn of the century brick roundhouse. I thought that buying brickface styrene and assembling would be beyond my skills, so from photos of the prototype, I built the walls in Sketchup. However, there's no way I can take the time (is it even possible) to build the brick detail in Sketchup brick by brick. However, there's a perfect old brick texture that can be added via Sketchup's paint bucket. I suspect however, trying to get fine brick detail would be beyond Shapeways capabilities. I may send a small wall section to them as a test, but does anyone have any thoughts on how I might best do this?

Thanks

You did not mention using a home 3D printer. While there is a large up front cost, currently around $200 to $1000 depending on the size of the printer, the cost of printed parts is much lower.

I printed a 9" long bridge for my layout which used less than 50 cents worth of plastic.

For Mac users there is Turbocad Mac which works with 3D printers. I use a Makerbot printer and extrude ABS, which comes in various colors. It can print objects with holes. Orientation of your printed design determines what can be printed.

This is perfect start for trains in the field of 3d printing. http://www.playboxhd.org I hope that turns into reality soon.

I have several models available through Shapeways. I to have experienced all the printing follies Alex mentioned. When the price of printing comes down, I expect more will use the service. I the mean time you have an opportunity to invest in models not available through the usual sources.

A good general overview. Shapeways FUD is excellent but VERY expensive. Where it shines is for making parts to use as masters for casting (which is what I am using it for). WSF is certainly cheaper but the detail is nowhere near as crisp as FUD and it is porous. You need to seal it if you want to paint it or use as a master for RTV silicone molds. If you go to the Shapeways blog and YouTube, you can search for posts/videos on how to seal it.

SketchUp and Shapeways have been a boon. I've been challenged and frustrated but it's been fun learning how to deal with the idiosyncrasies of each. And since I model a niche prototype (rapid transit), 3-D printing and CAD are the way to go.

More in-depth articles about these subjects, please.