For the first time in plastic, ready-to- run models representing Union Pacific’s first two classes of 4-6-6-4 Challenger locomotives are available in HO scale from Athearn Trains. Part of the firm’s Genesis series, these steam locomotives feature prototype-specific detail that rivals brass models.

No shelf queens, these locomotives are also available with an ESU LokSound Select dual-mode decoder that offers realistic sound on Digital Command Control and direct-current layouts. The decoders are also the first we’ve tested with the ESU Full Throttle Steam sound and effects package.

The prototype. The American Locomotive Co. delivered the first 4-6-6-4 locomotives, numbered 3900 to 3914, to the Union Pacific RR in 1936. These were dubbed the Challenger Simple Articulated or CSA-1 class. The following year the railroad received 25 near duplicates, classed CSA-2.

Unlike compound Mallet articulateds that crawled along with drag freights, the Challengers had two sets of high- pressure cylinders and could reach passenger train speeds. The locomotives also had an impressive starting tractive effort of 97,400 pounds.

Although originally built to haul fast freight up the UP Wyoming Division’s Wahsatch grade, the CSA-1 and -2 Challengers would hold a variety of assignments over their long careers, including passenger service. Depending upon their operating territory, they could also be equipped to burn either coal or oil. These first Challengers would influence the development of the 65 larger “Jabelmann” Challengers built in the 1940s.

The model. Our review sample is decorated for no. 3707, using the correct aluminum-colored printing. The model’s prototype was built by Alco in 1936 as no. 3907 and burned coal for fuel. In 1944 it was converted to burn oil and renumbered 3807. In 1949, the locomotive became no. 3707 when it was converted back to coal and sent along with several other Challengers to serve on the Nebraska and Wyoming Divisions, where an unexpected traffic surge caused a motive power shortage. After less than a year, the UP converted these Challengers back to oil burning and gave them their old numbers. Number 3807, formerly 3707, was scrapped in 1957.

The major dimensions of the Athearn model are within scale inches of official Union Pacific prototype diagrams found in The Challenger Locomotives (Kratville Publications, 1980).

The locomotive and tender feature well-defined molded detail, including boiler bands and rivet seams. Our review sample also has a cast pilot that’s correct for no. 3707, as well the large domes and single smokestack of the prototype. Other road numbers offered by Athearn have footboard, boiler-tube, or steel-bar pilots as well as double smokestacks or original smaller domes as appropriate for their prototypes.

Separately applied details include all piping and handrails. The whistle and bell are painted to simulate brass, and the ashpan dump wheel, on the engineer’s side under the firebox, is painted red. There are also opening cab roof vents and a cab apron. The cab interior features seats, but no figures, and a painted and detailed backhead.

The mechanism. A die-cast metal insert surrounds the flywheel-equipped motor inside the plastic boiler. Worm shafts connect the motor to the second axle on the first engine and the third axle of the rear engine. The metal siderods transfer power to the other driver axles.

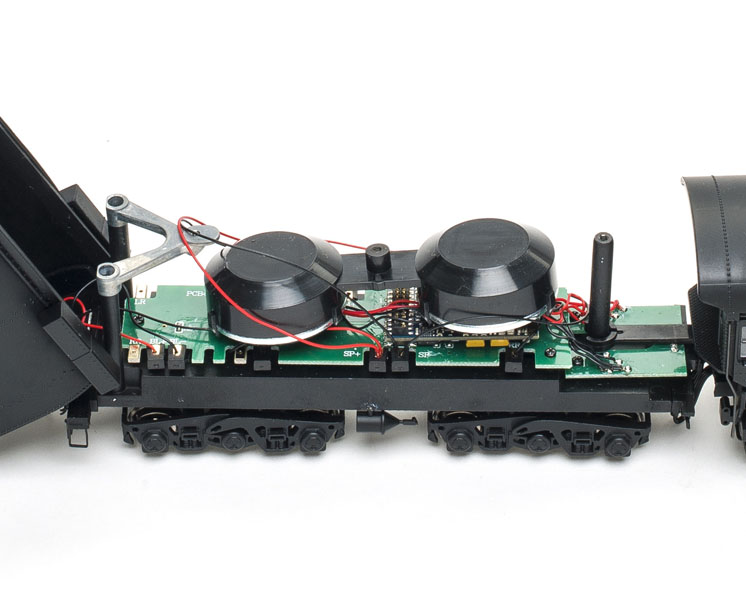

After removing three screws from the tender deck (one concealed under the coal bunker and two under separate water hatches), I easily lifted off the plastic tender shell. The tender houses the ESU LokSound decoder and two downward-facing 28mm round speakers in plastic enclosures. An eight-pin wiring harness connects the decoder to the electronics in the locomotive.

So it can negotiate tight model railroad curves, the model’s front and rear engines pivot. On a prototype articulated locomotive, only the front engine pivots.

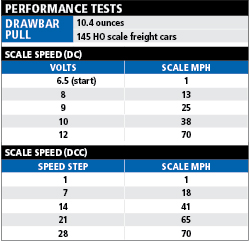

Performance. As you can see in the charts on the previous page, the model performed well in DC and DCC tests. In both modes the model accelerated smoothly from a scale 1 mph crawl to a prototypical top speed of 70 scale mph.

The model is factory equipped with four vinyl traction tires. These are installed on the second drivers of the first engine and the third drivers of the rear engine. Out of the box the model has a tremendous drawbar pull on straight and level track, also shown in the performance charts.

However, on the 3 percent climb to Skyridge on our staff layout, the Milwaukee, Racine & Troy, the front traction tires dug in, causing the Challenger’s front engine to lift up. The longer the train, the worse this bobbing became. This motion would eventually derail the pilot wheels, since the pilot truck is connected to the front engine.

To solve the issue, I removed the traction tires from the front engine. The locomotive then hauled a 20-car train up the 3 percent train without incident. Even with the front traction tires removed, the locomotive had an 8 ounce drawbar pull that’s equivalent to 112 HO freight cars on level track.

Full Throttle Steam. Like the diesel version, the ESU LokSound Full Throttle Steam effects package includes a function-button-controlled brake and Drive/Hold. The latter feature disengages the exhaust sound from speed control. When Drive/Hold is applied the speed remains constant, while the throttle adjusts the intensity of the chuffs.

The steam version also includes Heavy Load and Coast functionality that can be used with or without Drive/Hold. The varying intensity and volume of the chuffs (or lack thereof in the case of Coast) can also be programmed.

By default the Challenger is programmed for Heavy Load with Drive/Hold. Coast wasn’t enabled, so I programmed it on function 6 without Drive/Hold. On a long downgrade, I pressed function 6, the chuffs diminished to a whisper, and I heard prominent rod clanks and snifter valves. The throttle knob then controlled only the locomotive speed.

Using an ESU LokProgrammer (sold separately, although the software is available for free) made programming the decoder a much simpler task. For other detailed configuration variable (CV) lists and programming tips, free online user manuals are available for download at www.esu.eu/en.

As with other LokSound Select decoders, there are CVs that can be programmed to adjust every aspect of the decoder’s sound, lights, and performance. For example, I used CVs 57 and 58 (programmed to values of 77 and 121, respectively) to synchronize the exhaust chuff sound to the motion of the locomotive drivers.

The exhaust is also correct for a simple articulated locomotive. I could hear double chuffs, simulating the sound of the front and rear steam engines.

The default whistle sound was recorded from UP 4-8-4 Northern no. 844. In addition to long and short whistle blasts, user-triggered features include the bell, coupler, injector, grade-crossing signal, and several other effects.

The attention to detail of the automatic sound effects is impressive. After braking to a stop, the air pump sounds would come on. When starting out, the cylinder cocks would open automatically, and I heard the sounds of blowing down the cylinders.

On a DC layout, the sounds are limited to exhaust chuffs as the locomotive was in motion and brake sounds when I decreased the power pack voltage. The headlight and tender backup light operated according to direction. The red emergency light also came on in reverse. Running the locomotive with an analog sound controller, such as a Model Rectifier Corp. Tech 6, allows access to more user-controlled effects.

Athearn’s early Challengers will fill a hole in the rosters of many UP steam fans. Especially for DCC users, the ESU LokSound Full Throttle decoder ensures that the sound is as superdetailed as the model.

Price: $629.98 (DCC sound), $529.98 (DC no sound)

Manufacturer

Athearn Trains

1600 Forbes Way, Suite 120

Long Beach, CA 90810

www.athearn.com

Era: 1936 to late 1950s (1949 to 1950 as no. 3707)

Road numbers (all Union Pacific): CSA-1 (coal): nos. 3707, 3710, 3901. CSA-1 (oil): nos. 3802, 3813. CSA-2 (coal): nos. 3923, 3937. CSA-2 (oil): 3827

Features

Electrical pickup on eight drivers and all tender wheels (pickup on 10 drivers with traction tires removed)

ESU LokSound decoder (DCC version)

Five-pole skew-wound motor with dual brass flywheels

Light-emitting diode (LED) headlight and tender backup light

McHenry plastic knuckle coupler on rear of tender at correct height

Minimum radius: 18″ (22″ recommended)

Red emergency stop light on tender

Weight: 2 pounds, 3.5 ounces (engine alone weighs 1 pound, 8 ounces)