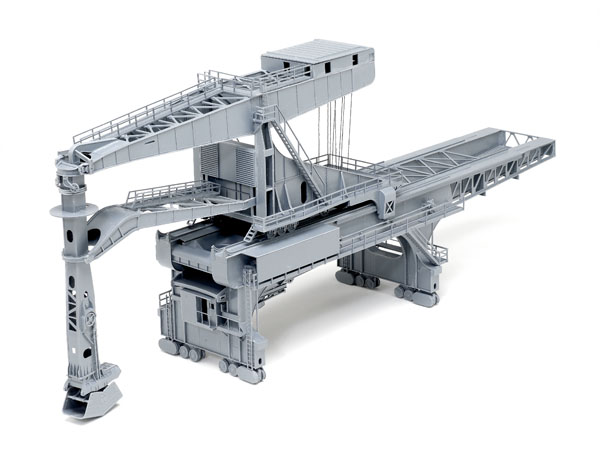

Each machine was custom-built, but they share a common design that Walthers has captured in this interesting model. The Huletts came in a variety of sizes, and this is one of the more compact units.

Four tracks fit underneath, but the clearances are close. In its standby position, with the bucket sitting on the ore hopper, the model is an impressive scale 125 feet long, 34 feet wide, and 85 feet tall.

A different breed. Opening the box revealed a pile of 17 sprues of strange-shaped parts. A well-illustrated 12-page instruction booklet is included, and everything is number coded.

Assembly goes well, but keep the instructions handy and leave the parts on the sprues until they’re needed. I used a hobby knife, sprue cutters, a small flat file, and liquid plastic cement to build the kit.

The kit is divided into two large subassemblies starting with the base, which is like building a girder bridge that moves. It’s supported by four huge eight-wheel trucks that allow the Hulett to move sideways along the dock on four rails (not included). This base spans four tracks where hoppers are loaded beneath the machine. A moveable ore receiving hopper and scale sits on the top level of the bridge, while a larry car on the lower level transfers the inbound ore into the hopper cars underneath.

The second subassembly is the main carriage that rides on top of the base, and it can be moved to position the bucket. A massive walking beam tips back and forth to raise and lower the bucket leg. One operator controls the machine from a small cab built into the leg just above the bucket, and a stabil-izing arm keeps the leg vertical. If you’re careful with the cement, the completed bucket can be opened and closed and the leg will rotate.

The kit is cleanly molded in dark gray styrene. However, I plan to paint it grayish-black and add a patina of rust and iron ore dust.

Overall, I spent about 21 hours building the Hulett. It was a challenging project, but great fun.

For modelers, the next challenge will be figuring out how to animate one of these mechanical monsters.

Get instant access to more than 725 product reviews and videos. Subscribe to Model Railroader today!

Price: $169.98

Manufacturer:

Wm. K. Walthers Inc.

P.O. Box 3039

Milwaukee, WI 53201

www.walthers.com

Era: 1900 to 1990s

See a video of real Hulett unloaders in action below.

It's great that this piece of railroad / industrial history has been preserved in video.

How long did it take to unload an average ship?

Who will be the first modeler to build an operating model using the Walthers kit and DCC?

I was a great lake captain and I have had vessels unloaded by these hulett's. They did not carry much in there buckets seem like 35 to 40 tons, but they were fast four of them could unload the old lakers in about 18 to 24 hours.

What killed them the ships got bigger in size from ave of 550 feet to 730 feet, and as Mr. Zamirowski said the self unloader came around and the size of the ship went to 1000 feet. Tonnage over this time went from 6/8 thousand to over 61,000.

I remember seeing these work in Ashtabula Harbor. There is a part of one on display there at Point Park which overlooks the coal yard and marina.

This is a very impress machine monster!

I saw a lots of videos and fotos of this machine.

Its great!!!

I also grew up in Cleveland and was fascinated to watch the Hulletts operating. It is sad that they haven't found funds and a location where the remaining one can be reassembled.

Excellent and interesting. Would like to see more videos of this type, showing how some of the more odd and even common railcar loading / unloading equipment works.

Wow neat video, I can see why they replaced them however, looks labor intensive with multiple operators, what was their successor?

Just looked at the youtube video. The bucket looks like it came out of my old erector set.

Fantastic! Nice stuff… I'd never seen one in action.

Thanks

Many thanks for a supperb video, this brought back memories of when i was an officer in the merchant marine,i will have to look at a small shelf layout incorperating this model

PATRICK

DUBLIN IRELAND

Great video, thanks for giving me the oppertunity to see it in action.

I saw many of these in action when I was a boy in Cleveland, Ohio. My wife is from Ashtabula, Ohio just 10 miles from Conneaut where the Hulett was invented. It appears that the video was the Pennsy docks in Cleveland,

Great video and a stunning reproduction of the Hullett. It was mentioned in the article about animating the model and in searching for other video fottage of the unloader on Youtube there is a video of a scratch built model (not sure of the scale) that is fully functional. It gives a functioal point from a model, may be helpful for the daring modeler looking to automate the giant for their layout

This does look to be a really nice model – too bad I don't need one!

The Lehigh Valley had Huletts at it's New Jersey Claremont Terminal location. Claremont Terminal was built between 1917 and 1923. These were supposed to be used for the unloading of import ore ships for the Bethlehem Steel Company in Bethlehem, PA.

Gil

Walthers has out did themseves with this model. The model conforms quite closely to Mike Rabbit's plans of a Hulett. The level of detail is great, and moving parts are a great plus. I can't wait for one in N scale by Walthers

Very interesting video,i too was wondering how thy worked

seams like along tedius job. how long did it take to unload

the ship?

Thank goodness someone had the foresight to make the video-

really interesting to watch , so thank you .

I wonder if they were still in operation , our health and safety

would allow the operator to descend into the hatch .

Video was very helpful when it came time to weather the model. One caution: The operating joints, particularly the trunions on the walking beam, are fragile and break off easily.

Great video. My Grandmother used to take us to see the unloaders at the Port of Lorain, Ohio. These unloaded hoppers into boats, then were kicked up a high ramp to change tracks and get into the empty track. Sort of like a hump yard. Anyone know what these were called or if there is video for them as well? Tracks belonged to N&W if I remember correctly.

I just ordered one, now I will have to extend my steel works. I really enjoyed the film. Walters does a fine job on most of their models. Keep up the great work.

I worked at U S Steel in Gary and they had about six Huletts until a microburst or tornado knocked them over leaving one or two standing upright; the others were toppled like dominos. At the time, the Huletts were on their way out since ore boats were self-unloading. It took a heck of a long time to cut apart those beasts safely.

U S Steel unloaded boats into huge pits and moved the ore via conveyors.

Fabulous model from Walthers. The actual Hulett is an amazing piece of engineering – I've never seen anything like it. The video leaves us in no doubt as to how it operated and, as such, is an invaluable aid for any layout as well as weathering the model.

I agree, fantastic video. I saw them at Whiskey Island just west of Cleveland, Oh. By the time I saw them they were out of service but luckily one is to be saved for display. As an aside; the operation at Whiskey Island used to be huge with room for thousands of hoppers.

Most interesting… I wondered how they worked… Thanks!

How do the operators not suck in all that ore dust?