The Chesapeake & Ohio bought the first of an eventual 60 class H-8 engines from the Lima Locomotive Works in 1941, and they were the ultimate expression of Lima’s “Super Power” approach to locomotive construction. Few locomotives were built with a six-wheel trailing truck, but on this one it was clearly necessary to support the gargantuan firebox. With a boiler in proportion to its furnace and driving wheels tall enough to realize its speed potential, the 2-6-6-6 was one of the largest and most powerful steam locomotives ever built.

It was extremely heavy, too, and had axle loadings that only a railroad as well-built as the C&O could tolerate. For that and other reasons (the “D” word) the design wasn’t widely emulated, but in 1944 the Virginian Ry. purchased eight copies of the C&O 2-6-6-6 and designated them class AG. The final C&O H-8s were delivered in 1948, the year before Lima built its last steamer, and H-8s remained in service only until July 1956. The Virginian engines were retired a year earlier.

Two C&O Alleghenies have been preserved, one at the Henry Ford Museum in Dearborn, Mich., the other in Baltimore at the Baltimore & Ohio Museum.

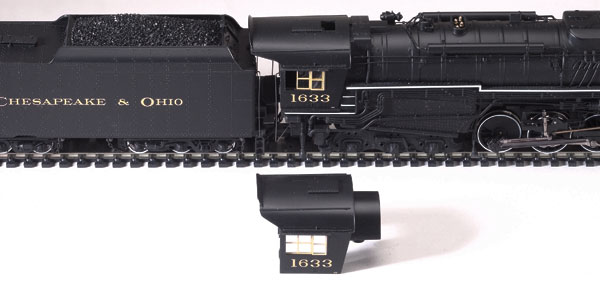

The Rivarossi model is plastic and metal and comes ready-to-run except for the installation of several details. These include cab and tender handrails, locomotive brake hangers, and tender truck safety chains. The latter require patience to secure with small pins at each end, but they add an extra bit of fascination that’s worth the time. I applied the water connections under the front of the tender, but not the water supply hoses from the locomotive. These can’t flex like the real ones and are only suited for static display.

While I was at it I installed the scale-length cab. This model comes with two, the short one having a roof overhang of 2′-7″, which is meant to clear the tender when operating the model on radii down to 16″! The full-length cab roof caused no interference on 22″-radius curves, and it’s more in proportion to the engine and tender. Detailing and cab swapping are all clearly explained in illustrated trilingual instructions.

The engine and tender have factory-added separate railings, pipes, and parts and compare favorably with most handbuilt brass models of this prototype. I enjoyed noticing the perforated running boards on each side of the firebox, which on the real engine allowed condensation from the safety valves, blowdown muffler, and steam dynamo to drain. The cab windows and ventilator hatch can slide open or closed, and the tender’s water hatches hinge open.

Dimensionally the model is quite accurate, for the most part differing only slightly from railroad dimensional diagrams and HO scale drawings in the Locomotive Cyclopedia, Vol. 1, from Hundman Publishing. The engine is about a foot longer than scale, and the driving wheel diameter is 64″ instead of 67″. These are both compromises that model makers often accept in the interest of functional scale models. The 3″ undersize drivers might be more apparent on a smaller locomotive, but under the hulking H-8 boiler the discrepancy isn’t obvious to my eye. The driver tires are thinner than is usual on many models, and that helps the illusion.

The model carries road number 1633, marking it as an engine from the fourth order of C&O H-8s, engines 1630 through 1644, built in 1944. They were basically the same as the 1941 locomotives, but there were piping and other detail variations among the first four groups. The model’s detailing accurately represents a member of the fourth series.

The rods and Baker valve gear are finely made and darkened to a steely color. Even the lubricator cranks driven from the combination levers are accurately modeled. The one flaw in this running gear is that the eccentric cranks on the left side of the engine are backwards. They should lean forward when the crankpins are at bottom dead center, but instead they lean to the rear. I didn’t see any easy way to correct this.

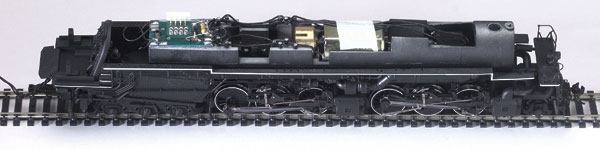

The model is powered by a flat can motor mounted centrally within the boiler. The motor has a flywheel on one end and connects through universal shafts to gear towers on both the front and rear engines. There’s one plastic traction tire, on the left-hand wheel of the fifth axle.

The pickup arrangement of this engine is a little unusual: The locomotive picks up from the right-hand rail with its pilot wheel and first and third drivers, and from the left-hand rail with its fourth and sixth drivers and first two trailing wheels.

The locomotive can run independently of the tender, but the tender picks up too. It takes current from the front truck’s first and third left-hand wheels and all four right-hand wheels of the rear truck. A flexible three-wire cable from under the cab plugs into the front of the tender, and with that connection the pickup footprint includes six wheels on the left and seven on the right.

The H-8 ran smoothly with no evident “traction-tire wobble” and only a little gear noise throughout an excellent speed range. With its weight and traction tire it’s an extremely powerful puller. On straight, level track, its eight-ounce drawbar pull equals 120 free-rolling freight cars!

In common with earlier Rivarossi models, both engines swivel like trucks. On real articulateds like the H-8, the rear engine is rigid and the front engine swings radially from a hinge between the rear cylinders. Rivarossi’s arrangement is a concession to sharp curves.

With the scale-length cab and the shortest operational drawbar setting, the locomotive and tender had no trouble negotiating 22″-radius curves, 2″ sharper than the manufacturer recommends for this setup. However, even with double articulation the boiler and cab overhang were extreme, and the model looks its best on larger curves.

The wheel contour conforms to National Model Railroad Association standard S-4, with flanges .035″ deep, no problem even on code 70 flex- or handlaid track. Most of the wheelsets were in gauge. Although the fourth and fifth driver pairs were a little tight, they ran through Atlas no. 4 and 6 Custom-Line turnouts with no trouble. To correct the gauge, remove the drivers as shown in the instructions and pull them apart with a wheel puller. Don’t try twisting steam-engine drivers on their axles because this spoils the quartering, the 90-degree offset between the crankpins on opposite sides.

The front coupler height is correct, but the rear coupler was about half a knuckle too high compared to the Kadee no. 205 height gauge. I substituted a Kadee no. 25 coupler, which has the shank offset to the top of the coupler head, and that was just right.

The H-8’s headlight and backup light are wired for directional lighting, but their brightness varies with the track voltage. There’s also a red light inside the backhead for a fiery glow through open fire doors.

For command control there’s an NMRA- recommended socket on the circuit board inside the firebox. Remove the dummy plug that allows conventional operation and you can plug in a DCC decoder or other type of receiver.

There’s room for the decoder in the firebox, too, behind the weight and circuit board. This space is 33/64″ long, 1 3/16″ wide, and 15/16″ high. The instructions refer to a Rivarossi decoder, but it’s not yet available from Walthers. There are several decoders of a suitable size and current capacity; I tried a North Coast Engineering D15SR with good results.

The C&O used these 8,000-hp brutes in every kind of mainline service, including mountain coal drags, scheduled manifest freights, and even for passenger trains. The Rivarossi H-8 will do just as well on your HO railroad and serve as a worthy reminder of a notable prototype.

Price: $585

Manufacturer and importer:

Rivarossi, imported exclusively by Wm. K. Walthers Inc.

P.O. Box 3039

Milwaukee, WI 53201

414-527-0770

www.walthers.com

Description:

Plastic and metal ready-to-run steam locomotive

Features:

Flat can motor with flywheel

Drawbar pull: 8 ounces

Twelve-wheel drive with 13-wheel electrical pickup

Engine and tender weight: 1 pound

14 ounces (1 pound 7 ounces for engine alone)

Minimum radius: 16″ (with included short-overhang cab)

Directional headlights

DCC decoder socket

Movable cab windows and ventilator, opening tender hatches

Front and rear magnetic knuckle couplers

Road name:

653-5454 Chesapeake & Ohio