An HO scale General Electric C39-8 diesel-electric locomotive gets the ScaleTrains.com Rivet Counter treatment. As with the N scale version that I reviewed in the August 2019 issue, this HO scale locomotive features roadname- and road number-specific detail. Our review sample also came equipped with an ESU LokSound V.5 decoder for authentic sound and lighting effects.

The prototype. Among the first of General Electric’s Dash 8 locomotive series was the six-axle C39-8. The locomotive featured microprocessor control and a 16-cylinder 7FDL16 engine that produced 3,900 horsepower.

General Electric produced 161 C39-8s from 1984 to 1987, with 139 going to Norfolk Southern. The remaining 22 went to Conrail. In 1998, when Norfolk Southern (NS) and CSX purchased Conrail, the two roads split up Conrail’s C39-8 fleet. Four of the nine CSX units received a new paint job, but the rest retained their Conrail blue liveries and were “patched” with a new number.

The model. The HO model matches the dimensions of a prototype C39-8 as shown in the Car and Locomotive Cyclopedia of American Practice, Fifth Edition (Simmons-Boardman, 1984).

Our review sample is meticulously detailed to match CSX no. 7484. The prototype was originally built as Conrail no. 6009 in 1986 and repainted into CSX livery in the early 2000s. All paint is smoothly applied. Logo and lettering placement match prototype photos.

The model’s plastic body shell is accurately detailed for its phase III prototype, including a six-panel radiator grill, square corner cab doors, and a separately applied brake wheel. Air intake and other grills are see-through. All handrails and grab irons are separately applied, as are sand lines, m.u. hoses, and uncoupling levers. Our model of no. 7484 matches the prototype’s early 2000s era with a retrofitted antenna and electronics equipment on its cab roof.

The plastic truck sideframes match prototype Adirondack (AD) trucks with cast-in serial numbers and AD logo. They also feature separately applied cylinders and rotating bearing caps.

The mechanism. After removing the coupler boxes, I lifted off the body shell. Note the instructions state there are no wires between the body and the chassis, but that’s incorrect. There are magnet wires connecting the lighting board to LEDs in the body shell. Care should be taken not to inadvertently tug these very fine wires loose.

A die-cast metal weight runs the length of the locomotive, partially encasing the flywheel-equipped motor. Truck-mounted gear boxes power all six axles. All 12 metal wheels pick up track power.

Mounted atop the weight, the main printed-circuit board has a 21-pin socket with the ESU LokSound V.5 decoder plugged into it. Two cube-type speakers are enclosed above the rear truck.

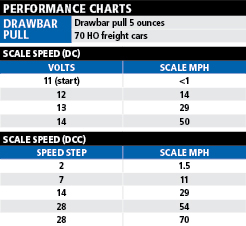

Performance. During DCC speed tests, the locomotive didn’t move until speed step 2, so I adjusted the starting voltage by programming configuration variable (CV) 2 to a value of 2. The locomotive then began rolling at less than 1 scale mph in speed step 1. The C39-8 accelerated smoothly to a prototypical top speed of 70 scale mph.

I also put the C39-8 on point of a freight train on our staff layout, the Milwaukee, Racine & Troy. The locomotive’s heft and pulling power let it haul a 15-car train up a winding 3 percent grade without stalling. The model also includes an ESU PowerPack capacitor system that keeps the lights and sound steady and motor running smoothly during brief power interruptions, like those due to dirty or uneven track.

User-triggered features include the bell, coupler, a dynamic brake sequence, and the Leslie air horn. Function 10 applies the independent brake that stops the locomotive, with appropriate sound effects. Function 9 triggers Drive/Hold, where the locomotive speed remains steady and the throttle knob can be used to manually notch the engine RPM.

Lighting effects include headlights, number boxes, ditch lights, and red marker lights. All can be triggered independently. The ditch lights also alternate when the horn is sounded.

Every sound, lighting, and performance aspect of the decoder can be adjusted with CVs. I programmed the decoder address to the locomotive cab number, added momentum, and increased the braking rate. I appreciated that the volume level of each sound effect can be adjusted independently. In addition to the included quick start guide, an extensive user manual can be downloaded for free at loksound.com.

I find it easiest to program LokSound decoders using an ESU LokProgrammer computer interface (MSRP $179.99) and the free LokProgrammer software. Note that even if you don’t purchase the interface, you can still download the user-friendly software to provide you with CV values that you can then enter manually into your DCC system.

On our direct-current (DC) test track, the model didn’t move and its sounds didn’t start until I applied 11V to the track. I remedied this by using my LokProgrammer to lower the analog starting voltage (CV 125) to a value of 53. At that setting, the sounds started at 6V, and the model crept along at 1 scale mph when I applied 7V to the track. It accelerated smoothly to 50 scale mph at 12V.

The only sounds available on a DC layout are the engine and squealing brakes, unless the model is operated with an analog DC sound controller, such as an MRC Tech 6.

Available in several prototype-specific versions, this HO scale C39-8 makes a fine addition to the superdetailed-out-of-the-box Rivet Counter series.

Price: $324.99 (DCC, sound);

$209.99 (DC, no sound)

Manufacturer

ScaleTrains.com

7598 Highway 411

Benton, TN 37307

scaletrains.com

Era: 1984 to 2000s; 2001 to 2005 as detailed and decorated for CSX no. 7484

Road names: CSX (YN2 scheme and ex-Conrail patch in “Quality” and “can opener” schemes), Conrail, General Electric demonstrator, Norfolk Southern, Pennsylvania Northeastern, Savage Ry., and Southern Alberta Ry. Multiple road numbers and paint scheme variations.

Features

• All-wheel drive and electrical pickup

• Blackened metal wheels, in gauge

• ESU LokSound V.5 decoder

• Five-pole, skew-wound motor with dual brass flywheels

• Light-emitting diode headlights, number boxes, ditch lights, and red marker lights

• Metal knuckle couplers at correct height

• Minimum radius: 18″ (22″ recommended)

• Operates on codes 70, 83, and 100 rail

• Weight: 1 pound 5.3 ounces