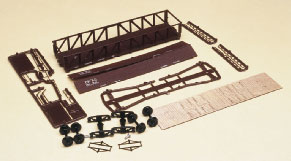

Upon opening the box you’ll find an injection-molded plastic sideframe and floor assembly, plastic ends, and assorted plastic detail parts. The most interesting material in the kit is the choice of laser-cut wood for the sides and decking.

The prototype for this model was one of seven standard freight car designs developed by the USRA during World War I (only five of the designs were built during the years of USRA control). Designers chose composite (wood and steel) construction to conserve as much sheet steel as possible for the war effort.

Next to the single-sheathed boxcar, the composite gondola was the most popular USRA-design car built with 20,000 cars delivered to 25 railroads. Missouri Pacific and Illinois Central led the pack, with 3,000 and 2,650 USRA composite gons respectively. Other railroads that rostered these cars included Atlantic Coast Line (300); Boston & Maine (1,500); Chicago & North Western (1,000); Chicago, Burlington & Quincy (1,000); Louisville & Nashville (1,000); Michigan Central (1,000); Nashville, Chattanooga & St. Louis (200); New York Central (1,000); Pennsylvania RR (750); St. Louis-San Francisco (1,000); Southern Ry. (2,000); and Wheeling & Lake Erie (1,000).

While all of these cars were built as composite cars with drop-bottom doors, many railroads later rebuilt these gons with steel sides. The Pennsy also removed the drop-bottom doors from many of its cars.

The InterMountain model is a nice one-evening project. I started it after supper and was done in plenty of time to watch the 10 o’clock news. The kit only requires simple modeling tools: a sharp hobby knife, tweezers, a pin vise with a no. 75 bit, and some liquid plastic cement and cyanoacrylate adhesive (CA). I didn’t encounter any problems, although I found it necessary to lightly sand the ends of the wood sides so they fit properly without bowing the plastic frame members.

The use of wood sides and floors may seem a step back to many modelers. As a general rule I don’t like wood models, particularly freight cars, since the wood grain almost never looks right to me. But in this case I like the floors and sides. One of the toughest modeling challenges is to make the wood sides on a composite car look radically different than the steel structural members. The design of this kit makes it easy to achieve a heavy, well-used look for the finished model, an ideal choice for a gondola. I haven’t weathered my model yet but I plan to add a black wash followed by liberal applications of powdered chalk, to tone down the bright wood floor.

No matter what your opinion of wood for rolling stock models there’s no arguing with the sharp appearance of the floor and sides. Particularly clever are the floorboard ends, which are cut into the bottom of the sides, and the door outlines in the floor.

The door outlines are also molded into the underside of the car. The model includes split K brakes and very nicely done Andrews trucks. The plastic wheelsets that came with our model were all in gauge and rolled well, although replacing them with 33″ metal wheels from InterMountain (or any other manufacturer) will add a bit of weight down low and considerably improve the rolling qualities of the car.

The completed car weighs just under an ounce, about 2.75 ounces lighter than the NMRA Recommended Practice for a 40-foot car. Adding a sheet of .060″ lead between the wood and plastic floors will get the weight to just above the RP. Reboxx (8 Henshaw St., Suite A, Woburn, MA 01801, www.reboxx.com) now offers a weight for this car as part no. 130-07.

The completed model matches drawings of the prototype car published in the May/June 1981 issue of Mainline Modeler. That same issue also includes prototype photos of many of the cars.

The CB&Q lettering on the model, which is remarkably sharp and in register considering it was printed onto wood and plastic, matches the prototype photo of a Q car exactly.

My only criticism of the kit is the fairly heavy plastic grab irons and stirrup steps. I’ll likely replace these with wire parts on future kits.

All in all the USRA composite gon is an innovative model that combines the best of old and new materials and technology. I think you’ll like it.

Price: $17.95 decorated, $13.95 undecorated

Manufacturer:

InterMountain Railway Co.

P. O. Box 839

Longmont, CO 80502-0839

800-472-2530

www.intermountain-railway.com

Description:

Injection-molded plastic kit with laser-cut wood sides and floor

Road names:

41601 Chicago, Burlington & Quincy

41602 Chicago & North Western

41603 Missouri Pacific

41604 New York Central

41699 undecorated

(decorated models available in 12 road numbers)