Folks, 71″ is a scale 947-foot-radius curve. While moderately sharp by prototype standards, an N scale train will certainly look good rolling along a curve that broad!

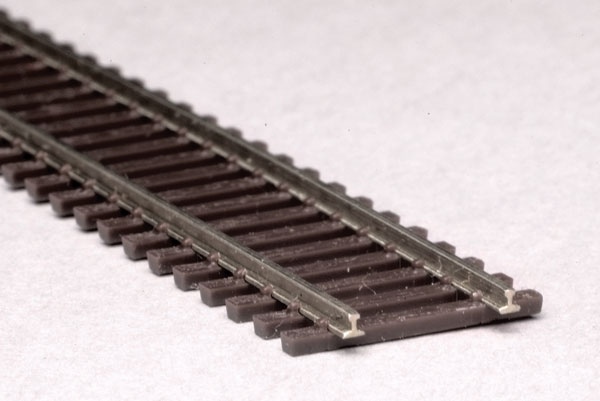

This track has finely cast brown plastic ties with simulated wood grain. The Atlas ties measure a scale 8′-6″ long, 8″ wide, 7″ high, and are spaced on 21″ centers. Prototype wooden ties today typically are 8′-6″ to 9 feet long, 9″ wide, and 7″ high on 20″ centers. As many modelers have learned, properly proportioned ties spaced closer together look better and improve the illusion of distance on our layouts.

Atlas’ code 55 flextrack curves as easily and smoothly as its code 80 counterpart. Some modelers these days are gluing down flextrack. If you still prefer to tack your track to the roadbed or pin it in place to align it, you’ll have to drill holes in the ties. Atlas has started this job for you on the underside of the ties.

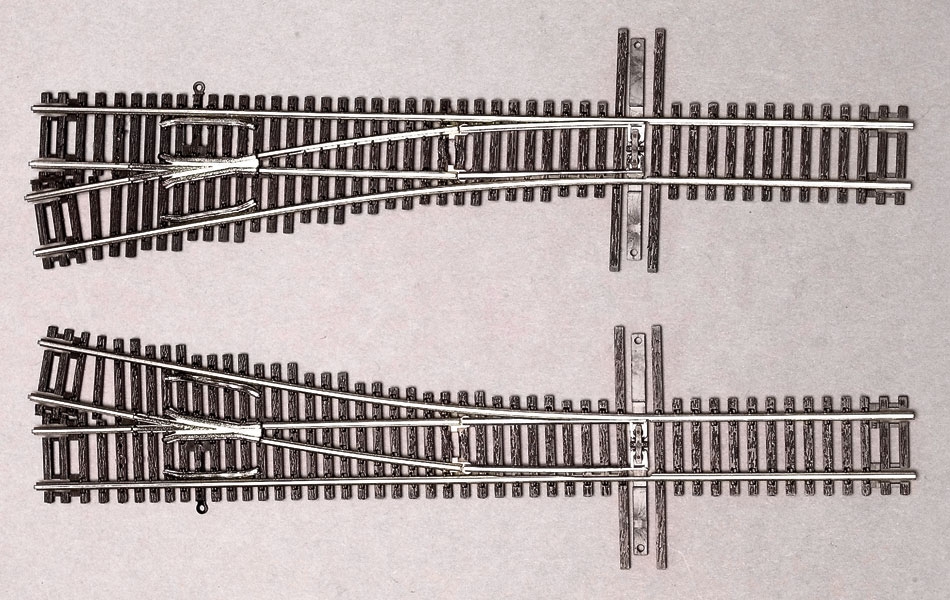

The lengths of the turnout ties increase incrementally starting at the fifth tie past the switch rod, reaching a maximum scale 15′-0″ length six ties past the point of the frog. From there the ties revert to standard length. The staggered effect shown in the photo on the next page is a nice touch of realism.

A plastic clip holds the points to the switch rod. There’s no toggle-action locking spring, so you’ll need a ground throw or switch motor to hold the points against the stock rails.

Extra long headblocks are cast as part of the tie strip. You should trim off the headblocks and switch rod after deciding on which side to place your switch stand or switch machine. My one concern about these otherwise well-built turnouts is the wide spacing (scale 39″ center to center) of the headblocks, as it’s a distraction.

The frogs, guardrails, and points are metal castings; the switch points and stock rails are connected internally. The points don’t route power, but the frogs are electrically insulated so you won’t have to cut gaps in front of the frog to prevent shorts.

I tested Model Railroader’s samples by running an Atlas RS-3 road switcher and a Life-Like PA-1 cab unit back and forth without a hitch.

If you decide to power the frog, Atlas includes an easy-to-follow diagram showing how it can be accomplished. You don’t necessarily have to use the Atlas Snap-Relay shown in the diagram, as a single-pole, double-throw switch that moves with the points, like those on a slow-motion switch motor, will do the same job. Atlas also offers an under-table switch machine.

The wire that powers the frog connects to a terminal Atlas has thoughtfully located on the straight side next to the guardrail. Ballast will easily hide this terminal.

Atlas’ code 55 rail joiners are sturdy metal stampings that slip on and off easily. The scale 9″ rail height and cross section is much closer to the prototype 7 5/16″ height of 140-pound heavy mainline rail than code 80 track which scales out more than 13″ tall. Our turnout and flextrack samples checked out with a National Model Railroad Association standards gauge.

Rather than faulting the code 55 Atlas track (as some have done), the incompatibility here is due to wheels that don’t comply with NMRA standards. The best fix is to replace the wheels with low-profile types offered by Atlas, InterMountain, Micro-Trains, or NorthWest Short Line.

Atlas continues to expand this code 55 track line, giving N scalers a terrific new track palette from which to choose.

Prices: See list below

Manufacturer:

Atlas Model Railroad Co., Inc.

378 Florence Ave.

Hillside, NJ 07205

www.atlasrr.com

Description:

Nickel-silver and plastic track

Product list:

Crossings, $6.50 each

Flextrack (30″ length), $2.95 each

No. 5 or no. 7 turnouts, $9.95 each

Rail joiners, 8/$2.25

Rail joiners (insulated), 6/$1.25

Sectional straights, $2.50-$3.95 each

Sectional curves in full and half-section assortments ranging from 10″ radius to 21¼” radius in 1¼” increments, $2.95-$3.95 each

Sectional curves, 30.609″ radius, $3.95 each

Sectional curves, 71″ radius, $5.50 each

Yes i have dissided to go the code 55 i think it looks the goods, and yes i have the problem of wheel flanges, not on the wagons as these are easily replaced, i mean my early Big Boys and Challengers and Mallets all with deep wheel flanges, so i hooked up power to the drive wheels, got them spinning and hit them with a small flat file, wheels on the front and back trucks, i hooked up a rubber band to the axles, then to the motor of the turn table motor, witch has the rubber band on it that drives the turn table,got the wheels spinning and hit them with the flat file, or finger nail file will do, now the flanges do not hit anymore, hope this helps those that want to keep there deep flange Locos on code 55 track.

Does anyone know or know where to get the radius measurements (inside, outside and or center) for the #5, #7 and #10 turnouts?

I have a problem with the Atlas code 55 turnouts….the castings of the frog and the points are not always in guage. Some of my engines bump over the frog, and get stuck between the guard and stock rail. This requires some filing to get smooth running over these places. I should not have to do this with a new product. Atlas needs to look at this problem. Has anyone else experienced this?

I agree with the author of the evaluation. Wheel sets with SMALLER flanges work fine I have many older wheelsets on cars from the 1960 & 1970's that need to be change d but it is worth it for the appearance & operation of those I've changed.

Patt Patterson

Arizona

Really realistic ,but flanges bumping the ties is a problem with some cars.

I was considering Code 80 for a while but after seeing the detail of the Code 55 I changed my mind. Little tough working the track plan but it pays off.

I'm just getting started but I have to agree with Mr. Paroby, the added realism is worth the effort.