Do you know how to switch model railroad freight cars? Operations, once considered a quirky art practiced by few, has become commonplace on today’s model railroads. As interest in operations increases the need for “boomers” – operators, in other words – has also increased. Therefore you may find yourself pressed into service on a new railroad with little or no experience under your belt. Fret not; if you know a few basics, you should be able to fake it and still have a good time.

Trailing point move. Setting out or picking up cars is a simple matter when it’s a trailing point turnout, where the locomotive approaches from the frog, heading toward the points. If locomotives aren’t permitted on the spur a “handle,” enough cars to allow the locomotive to reach into the spur, must be used.

Hitting the road

As you roll into the first town on the line your host gives you a few pointers on working the local. “You’ll need to cut off the first three and then run around to make the drops at Amalgamated Grain since that’s a facing point spur.” Once you arrive in town it doesn’t get any clearer: “The oil dealer will be a trailing point move from this side so it won’t take much time.”

“That sounds good,” you reply, filling your voice with false confidence while focusing on the throttle knob and trying to comprehend it all. I’ll explain the two most basic switching moves. Just enough, in other words, to make you dangerous.

Two basic switching moves

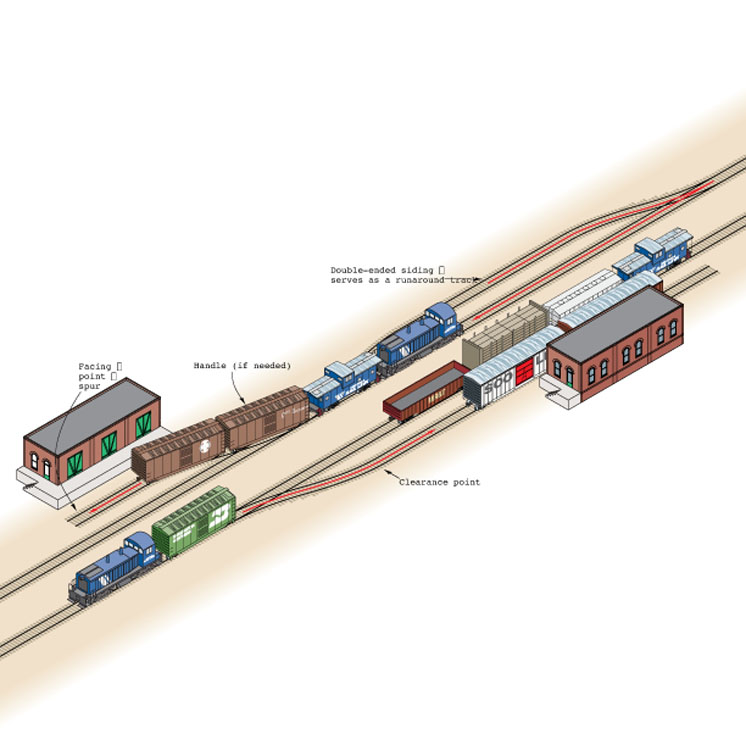

When the time comes to switch model railroad freight cars, you’ll soon find there are two types of switching moves. Which one you use depends on the track configuration relative to the direction of travel. The diagram shows both of them, called facing point and trailing point moves.

Setting out or picking up cars from a trailing point is fairly straightforward. Run the locomotive and cars to be dropped (or a “handle,” several extra cars that permit you to work the siding while keeping the engine off the siding) past the switch and stop. Make the “cut” (that’s railroader for “uncouple”) from the train, then run the engine forward until the points of the switch are clear, throw the switch and back into the spur, spotting the cars in the correct locations. Reverse the process, couple back onto your train, and the trailing point move is complete.

A facing point move, required when the engine approaches from the point side of the siding, is more time consuming. You first need to run around the train, requiring a double-ended siding.

The process shown in the diagram works great provided the runaround track is clear. If it’s fouled, you’ll need to clear it; just be sure to put the cars back where you found them!

If you need to use the main line as a runaround track you might have to obtain permission from the dispatcher.

What if you need to perform a facing point move and there’s no runaround track? Simply run around the setouts using a double-ended siding in another town and then shove the car(s) in front of the engine. This was quite common in the real world.

Another choice would be to leave the car in a temporary location (called an “off spot” track on most layouts I’ve operated) for the local heading the opposite way to drop off as a trailing point move.

That’s all there is to it. Oh, and be careful out there.