The 20th century saw a dramatic increase in railroad labor productivity. In 1916, the peak year for U.S. Class I railroad route-miles, those 100-plus carriers employed 1,559,158 people. If we assume 85 percent of those employees, or 1,325,284, were allocated to freight traffic — which totaled almost 339 billion ton-miles — this works out to 256,441 ton-miles per employee. Contrast this with 1999, when 228,000 freight railroad employees were handling 1.4 trillion ton-miles, or 6,287,110 per employee, 241⁄2 times as much.

Increased Train Size

A typical freight of 1916 might handle 2,000 trailing tons, of which — owing to a normal mix of loads and empties — less than half would represent revenue ton-miles. By 1999, many specialized trains existed, examples being unit coal and grain trains and double-stack container trains. Most unit trains are designed to operate one way empty to get the equipment back for the next load, but when considered as a round trip, i.e., only 50 percent loaded, the average round-trip move still would be of 7,000 trailing tons for a typical coal train and 5,500 for a typical grain train. Conventional “mixed merchandise” trains, with cars of various commodities and destinations, whether loaded and empty, similarly average to perhaps triple their 1916 equivalent.

Many factors contribute to increased train size: diesel power, enhanced by modern wheel-slip control and A.C. traction motors; cars that carry 100 tons or more on roller-bearing axles instead of 35 tons per loaded car with plain bearings; improved route profiles; and lower rolling resistance of track, for a long time now laid with heavier rail welded continuously on heavily ballasted roadbed.

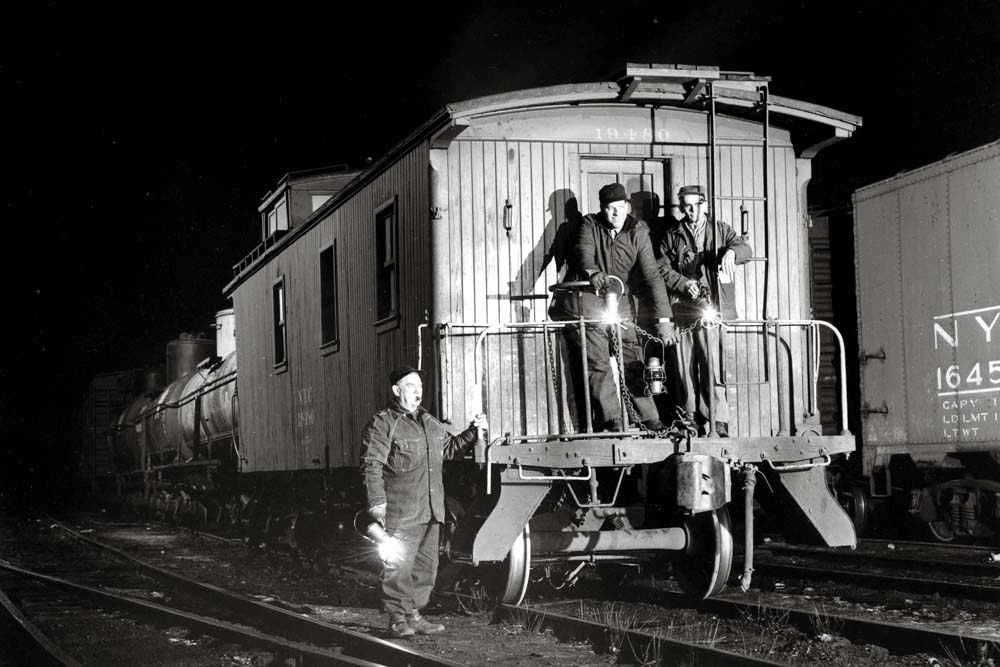

Crews Of Fewer Persons

Intelligent collective bargaining agreements, in which negotiators of both labor and management knew what had to be done to keep the industry competitive, still have provided the protection of attrition agreements for affected employees. Landmarks in this effort were the agreements of the 1970s and ’80s, which eliminated locomotive firemen and cabooses, and gradually reduced road-train crews from five persons to two. They also provided for direct delivery of trains to connections by road crews instead of using transfer crews, and allowed reciprocal interchange arrangements that enabled two-way loaded moves to replace the practice of a delivering crew returning “caboose light.” Many carriers negotiated run-through agreements that permitted one crew to go all the way through extended districts of over 200 miles. Usually this was accomplished by allocating the paid mileage between crews from two home terminals, running through what had been the away terminal for both.

The elimination of the caboose came about as technology advanced, with visual observation of the train from the rear end being replaced, and improved, by trackside failed-equipment detectors. Electronic rear-end devices handled former caboose air-brake functions.

Less Clerical Staff and Maintenance Forces

Once again, intelligent collective bargaining agreements resulted in adoption of labor-saving measures and taking advantage of advancing computer and communications technology. The range of these improvements has been vast, many being covered elsewhere in this issue, one example being the use of centralized traffic control. The concentration of train-dispatching and crew-calling for entire railroads from a single operations center resulted in large savings. Beyond operations, computers revolutionized accounting data, eliminating paper waybills and all the procedures that went with them. The role of automatic car identification has been critical.

In track maintenance, tampers replaced dozens of men tamping by hand, and combine in the same machine the functions of tamping and lining, which also required dozens of men shoving in rhythm on lining bars. The adoption of continuous welded rail on heavy ballast eliminated all the bolt-tightening and broken-bar replacement work that rail joints every 39 feet had required, not to mention the extra tamping at low joints that recurred so often under heavy traffic. The adoption of electronic flaw detection, both of rail flaws and deviations of line and surface, and now even of the state of tie condition and of rail-head wear, greatly reduced wasteful cycle maintenance, replaced with maintenance by observed condition. Besides allowing increased railroad labor productivity, these technological improvements have reduced accidents.

Improved Rolling Stock

Dieselization alone cut locomotive maintenance staff to less than one-fourth the number of employees that steam required, but since dieselization, other factors have helped. The advance from a typical road unit producing 1,500 horsepower to being rated at over 4,000, along with modular control circuits and more reliable engine components, have resulted in fewer units overall, hence reduced maintenance manpower.

Numerous factors have combined to greatly reduce the role of locomotive backshops as well. One is leasing, as units are returned to the lessor that otherwise would have required a heavy overhaul, but an even greater factor has been the adoption of running-shop maintenance based on condition, rather than on sending locomotives to the shops based only on mileage accumulated. Similarly, more frequent oil-sample testing, with results shared on daily conference calls, allow such things as changing pistons individually based on wear, rather than replacing them all at once based on mileage regardless of condition. Another factor contributing to this increase in condition-based maintenance has been, since the1980s, the practice of having manufacturer representatives on site at major shops to supervise maintenance, with parts inventory supplied under the terms of the lease.

Regarding freight-car maintenance, roller bearings are not lubricated in the field but are repacked in automated wheel shops during the replacement of one-wear wheels, because the wear mileage on the wheels coincides well with the reliable mileage attainable with sealed bearings. Further, the adoption of higher-capacity cars has meant fewer of them, thus a reduction in the maintenance-demanding coupling and air-brake systems of each car. Also, more rapid equipment turnarounds have helped reduce the size of car fleets, cutting the need for carshop employees.

The increased railroad labor productivity has allowed them to be among the best paid workers in American industry, and rightly so, because one thing has not changed — the 24/7 operation of the “industry without a roof.” Railroading, with its operating workforce dispersed and largely self-supervised over thousands of miles, responsible for massive, fast-moving trains, still demands a military-like discipline that disregards weather and time of day or day of week; requires drug-and-alcohol-free alertness at all times; and demands a work ethic and protect-your-fellow-worker ethos seldom found elsewhere in civilian life.

Working as a brakeman/flagman 2 1/2 years on Seaboard Coast Line Railroad ’73-’75, I never realised or appreciated that we, the 5 man crew on the local freights and road freights, were working by rather old fashioned methods and tradition. 2 years out of Miami’s Hialeah Yard and 7 months out of Waycross. The ‘Bow Line’ westward out of Waycross was unsignaled single track where we operated per paper train orders assigning who takes the siding, or not. and that was with the daily Chicago-Miami Amtrak, plus 2 days a week midwest Auto-Train thrown in to avoid delaying. Much more efficient now, I’m sure, but there was a lot of camaraderie back then, and it was simply a fun job. Best job in the world, so I thought. But I quit to join another ‘industry’ that was even more fun: blue water sailing. getting paid to sail the world on private yachts! Cheers All! cudjoebob, formerly R.E. Wallace SCL# 165362

Regarding Rule G, I think FRA, NTSB, and the Office of National Drug Control Policy still have concerns today, in spite of drug testing requirements.

I recall analysis of oil samples being used in the late 60s to identify parts needing replacement. Parts identified were bearings in different parts of the engine, piston rings, pistons, wrist pins, etc. But how is this used to identify individual pistons as indicated in this article?