One of the common drawbacks of tubular track, particularly older pieces, is inconsistent electrical conductivity. This is caused primarily by corrosion inside the rails interfering with the flow of power through the track pins. I tried a number of solutions, including soldering track together (bad idea), running jumper wires from center rail to center rail, and soldering wires across the track. However, none were easier, quicker, or more effective than this simple fix:

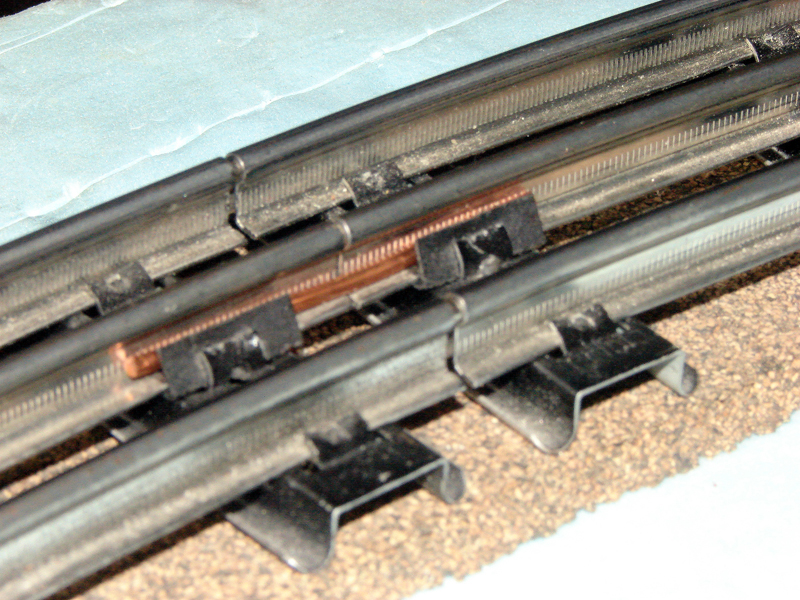

In places where you detect a drop in power from one section to another, install a power bridge by gently prying the center rail tie tabs up a bit and dropping a length of heavy copper wire between the tabs and the center rail.

Bend the tabs back into place snugly and you have instant and reliable power continuity. I would give the wire a very slight inward-facing bend so the ends of the wire contact each track section with some pressure.

In most cases, you can place the jumper wires on the side of the center rail opposite your viewing angle and never see them.

How would you do this onto rail ( Flyer) track?

“install a power bridge by gently prying the center rail tie tabs up a bit and dropping a length of heavy copper wire between the tabs and the center rail.”

How would it work to simply replace the center steel pin with a heavy copper wire that is the same diameter as the steel pin??