Most manuals or instructions sheets for locomotives or motorized units with traction tires discuss tire replacement. Consult your paperwork first. But generally, tire replacement is the same for either a steam locomotive or a diesel.

The main difference is access to the offending wheel. With a steamer, you need to remove or disconnect the side rod that’s attached to the wheel.

You need a screwdriver or a pair of pliers (depending on whether your model uses a conventional screw or some sort of hex nut).

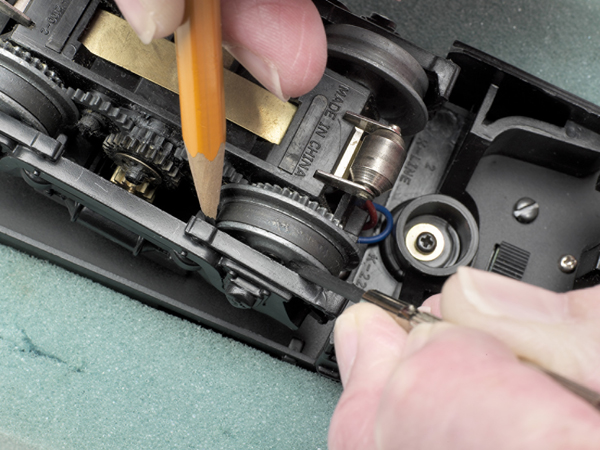

The main access problem for diesels relates to the truck side frame. While many modern locomotives are made with removable side frames (frames held onto the truck with two screws), many have been produced with frames that can’t be removed. These will be the toughest to crack since you’ll need to force the tire through the gap between the wheel and the frame.

Let’s go

Let me state the obvious: Not all traction tires are the same. Be sure you’re using a spare that came with your particular model – or a correct replacement tire you’ve found for your model.

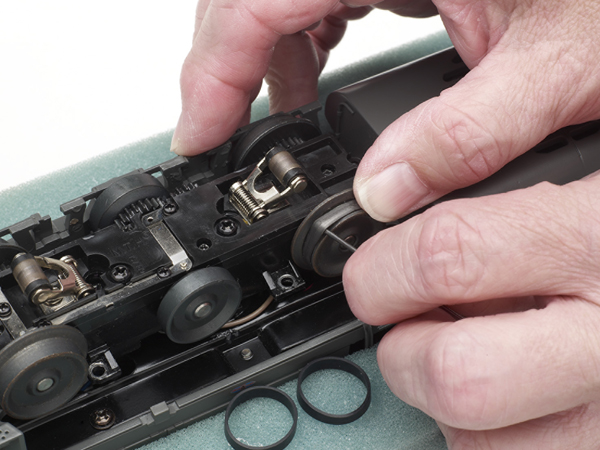

Like many things in this hobby, there are several paths to getting the job done. I like using two flat screwdrivers with small heads – think jewelry-repair size flat-heads.

Be sure that the old tire is completely removed, and check for small bits of rubber that may be stuck in the tire groove. The new tire must sit evenly in the groove.

I use a thumb to hold the tire in place and then use a screw driver to work around the wheel, getting the band up and over the outer rim of the wheel (the flange is on the inside of the wheel). I’ve run into a few tires that went on easily, but it can be a battle. After all, the tire is designed to stay tight on a small central axis, and the rim is a bit of a stretch. Literally.

Don’t be surprised if your tire breaks. That’s common with older tires that have been in a box for many years.

If you should twist part of your tire, remove it and re-install it.

Once the tire is in place, be sure it fits snugly in the recess in the wheel. Keep in mind that these aren’t exactingly engineered components for a space shuttle, so you may find your tire a bit wide in a spot or two.

If it otherwise fits, use a razor blade to trim the excess bits.

Once you are satisfied that the tire is snug and round (preventing a wobble), re-attach the truck side frame or side rod, place the locomotive on the track, and you’re good to go.

Very good advice. I just replaced a tire on a 634. I found that in order to have the drive wheels turn freely to place the new tire on I removed the commutator which also has the drive gear on the shaft. The wheel turned freely so I could replace the tire. This was a good time to clean out the old lube and replace with fresh. Matter of fact I cleaned up everything. The 634 runs very well in both directions.

At our club we have found that once you replace a tire, it’s a good idea to run your engine around in both directions for at least 3 to 5 minutes to seat the new tire. Note that this should be done with no attached consist.