Some questions we get frequently are: “How do I lubricate my locomotives?” followed by “What type of lubrication should I use on them?”

Here are some answers. And remember, when it comes to oil and grease on locomotives or other rolling stock, less is more.

Fortunately, there’s a quick and easy answer for what to use. At Kalmbachhobbystore.com we have a package that includes all the lubes you need for this job. When it comes to light lubrication, sewing machine oil will also fit the bill.

The Labelle package includes a light oil, a light gear lubricant, and micro gear grease with PTFE, better known as Teflon.

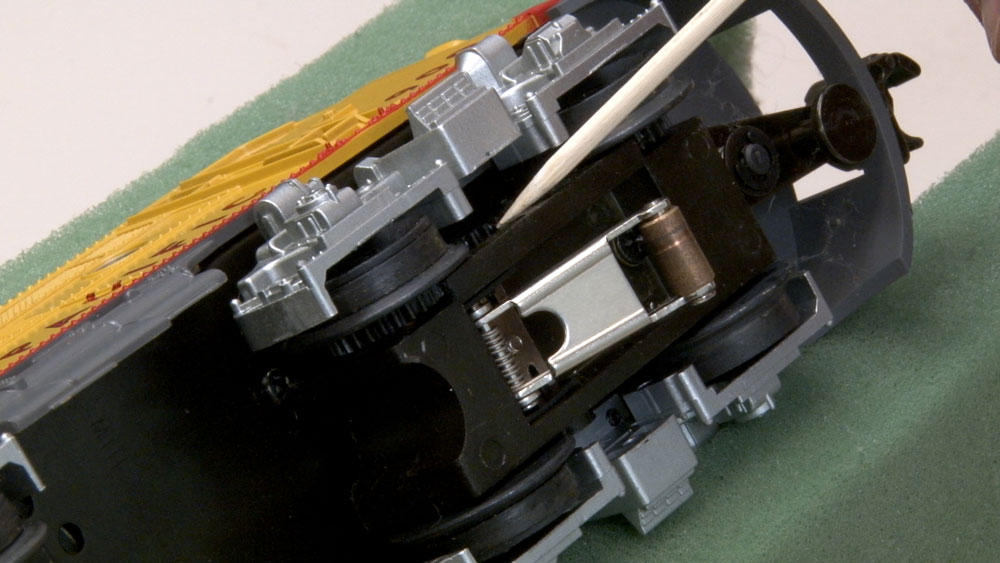

The first thing to do is apply the light gear lubricant, in this case Labelle 102, to the gears on the sides of the trucks. Remember, less is more here.

Instead of grease, I’ve used the light gear lube here because it’s less likely to attract hair, dirt, and other debris into the gears. Save the grease for worm gears and other moving surfaces that are harder to get to inside the engine.

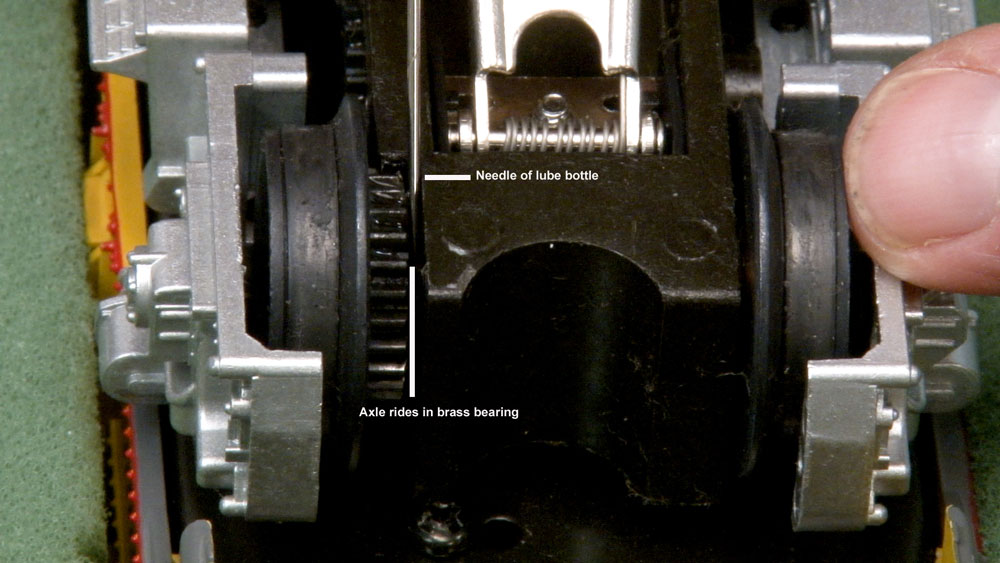

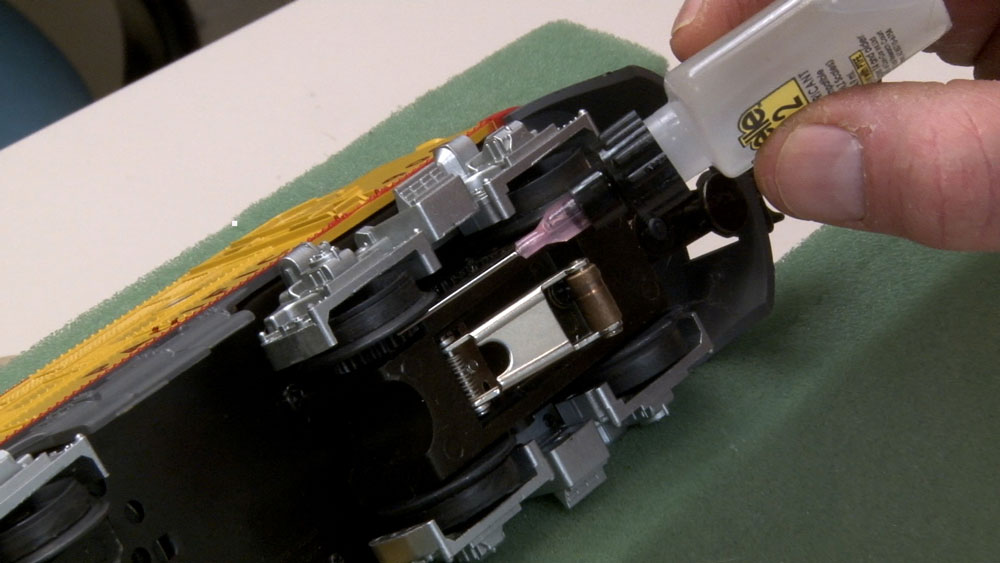

Next, I’ll apply a light oil to the axle bearings – In this case Labelle 107. If you look closely, there’s a brass bearing inside the block. A needle applicator on the bottle makes it easier to get between the wheel and the truck.

A little lubrication goes a long way. It helps protect your locomotives and rolling stock and keeps them running just like the day they were made.