Modern O scale rolling stock takes leaps and bounds in the level of detail and playability provided. Manufacturers roll out high end-looking models with some featuring not only traditional lighting, but also sound and smoke effects to further replicate real-life railroading. But what hasn’t fallen into the realm of head-spinning complexity is lubricating these 1:48-scaled items. Even after all these years, this routine maintenance remains as simple as lubricating O gauge postwar rolling stock.

Axles

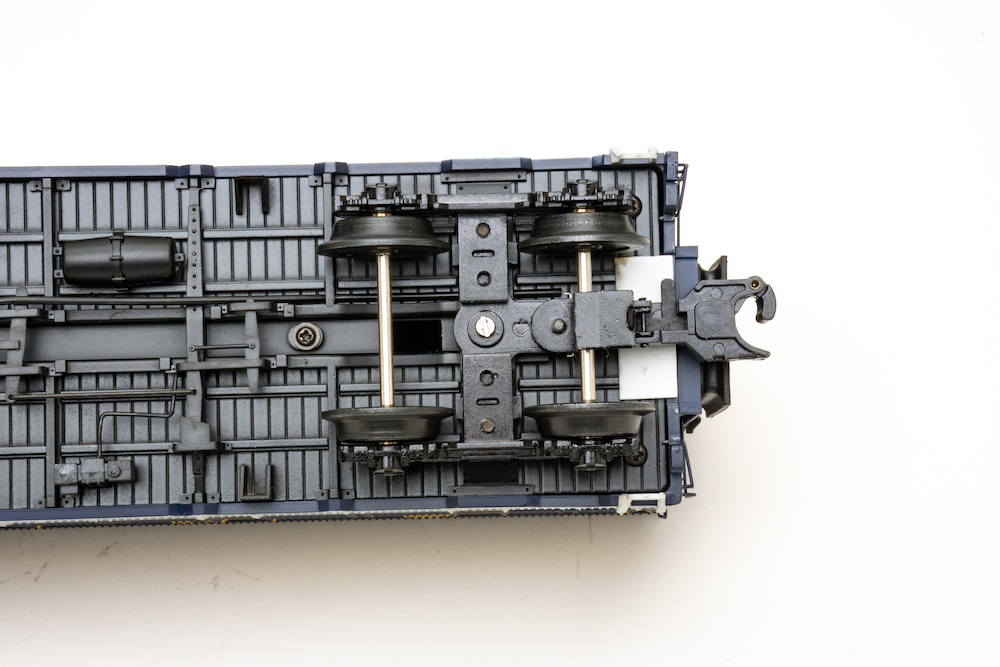

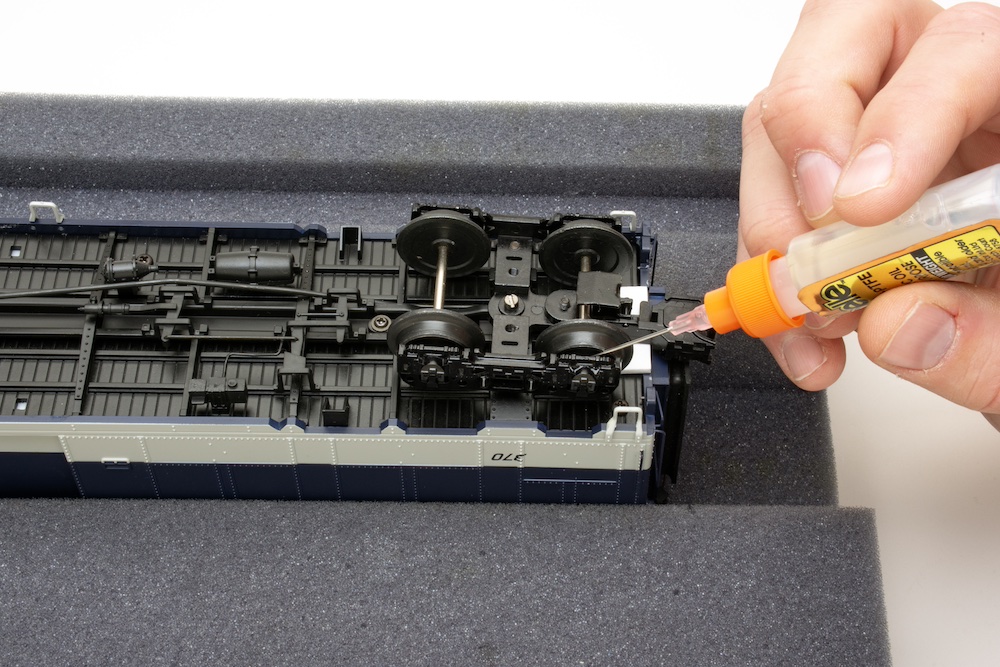

Like any equipment rolling down 3 rails, lubricating modern O scale rolling stock will involve every wheel set per car. The focus will be on the bearing boxes where the axles rest and ride on. The placements of the bearing boxes for each of the model’s trucks should first be identified. While most will have the traditional boxes on the outside at each end of an axle (partially concealing the wheels), some equipment, such as Amfleet passenger cars, will have inside bearing trucks with the wheels completely exposed.

Apply a light oil sparingly. Light oil prevents attracting debris when cars are running along the track, despite the outside exposure. Lubricants’ Nos. 107 and [occasionally] 108 are my go-to choices, and are available both online and at your nearby hobby shop. Regardless of purchasing them as a separate item or part of a kit, each lubricator will feature its own needle applicator. When applying the oil to the bearing, remember that “less is more.”

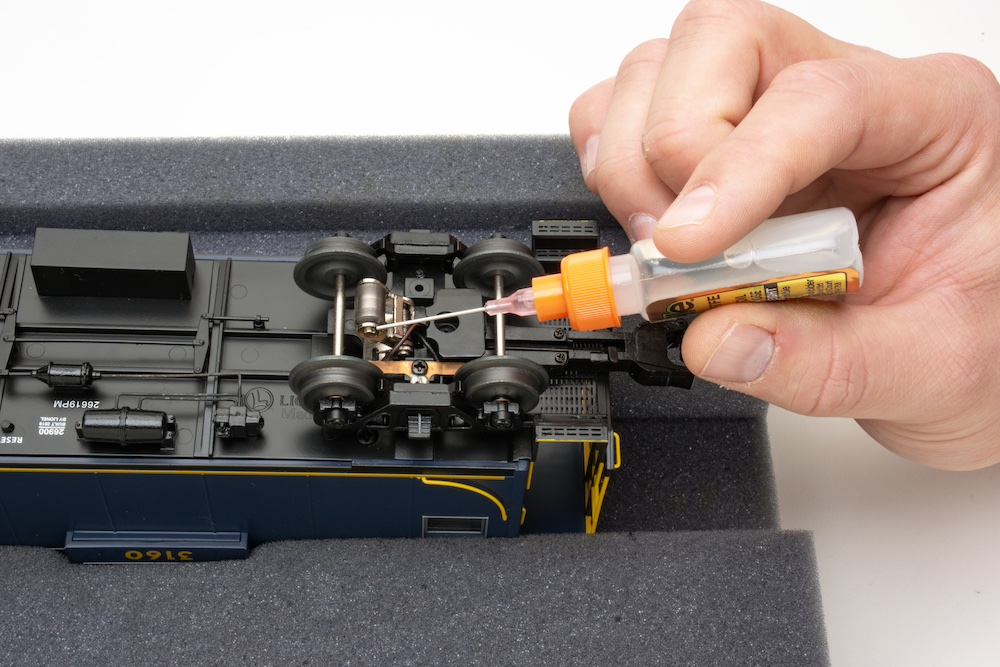

Pickup rollers

Despite all the high-tech wizardry from rolling stock with either lights, sound or smoke effects (or all of the above), the tried-and-true pickup rollers remain a staple in powering these features from the third rail. Apply a small drop of Labelle Lubricants’ No. 107 to the brackets’ pivots on the rollers, but take care as the general rule is to keep the latter oil-free.

“A little lubrication goes a long way”

After all the axles and pivots are oiled up, give the wheels and rollers a quick spin to let the oil set in. Adding on a healthy amount of run time along the layout afterward will go a long way for the lubrication to fill in all the nooks and crannies. Depending on how often you run, planning this routine maintenance on a regular basis will also go a long way in keeping your modern O scale rolling stock running, free from any trouble and squeaks.

Hi! What about cleaning wheels on modern rolling stock? Should this be done? What is best method? Thanks! Brad Adams.