“Less is more,” as the saying goes from the article How to lubricate your O and S gauge trains. The same applies to lubricating modern O scale steam locomotives, big and small. Though much like their real-life counterparts, there will be a few more components to attend to in contrast to lubricating diesels and rolling stock.

Running and valve gears

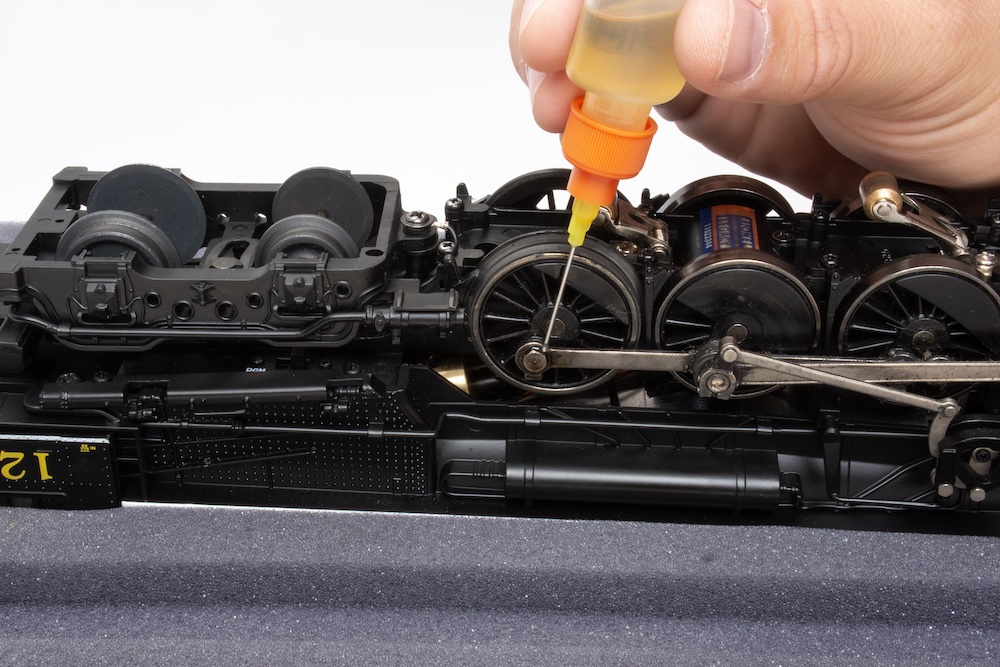

Those additional components will be the locomotive’s running and valve gears. Much like wheel axles (more on that shortly), a light oil is highly recommended for the proper lubrication while preventing the attraction of debris looking to find its way into the constantly rotating parts. Labelle Lubricants’ Nos. 107 and [occasionally] 108 oils with needle applicators are my choices and are available separately or in kits.

For every pin and screw that’s connecting the multiple rods and linkages, apply the light oil. The connections between the side rods and driving wheel are especially vital. When applying the oil, always apply the idea of less is more.

Axles

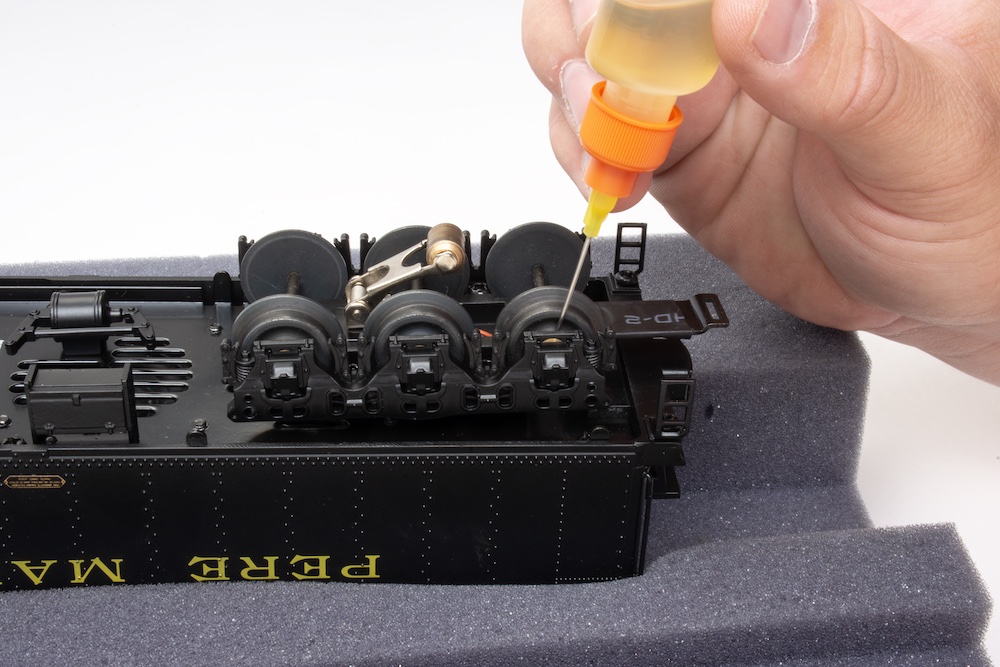

Much like a diesel or rolling stock, lubricating O scale steam locomotives will involve the bearings to the wheel axles. Include all of the wheels: Drivers, engine, trailing and tender trucks. Keep in mind the different placements of the bearing boxes along each axle before applying the light oil. That’s right, light oil will also be used sparingly here. I use Labelle No. 107 and its needle applicator.

Greasing gears

Most steam locomotives have their gear boxes enclosed, running along the middle of the driving wheel axles. Pending on the model’s size, some may require removing the body from the frame for access – please refer to your product’s instruction manual if you’re unsure. Other locomotives will have multiple screwheads at the bottom of the frame with “GREASE” inscriptions next to them. Remove the screw to reveal a cavity that will partly expose one of the gears well enough to apply the grease with little disassembly.

Unlike light gear lubricant for normally exposed components, micro gear grease with PTFE (Teflon) is acceptable to the concealed gears without the fear of collecting debris. I’m using Labelle No. 106, applying just a single dab into the cavity. Again, less is more.

“A little lubrication goes a long way”

Your mileage may vary on how often you need to lubricate your locomotives, year-round. Based on the amount of operating time for my steam fleet, I usually lubricate them every six months or so. As tedious as the task can be, especially when tackling Big Boy-sized models, it’s worth it for better reliability.