Let’s say you’ve got a ton of old Lionel track in your basement, or maybe someone is willing to give you a bunch for nothing. You want to build a layout, so you figure you can use this track to do it economically.

However, when you get a closer look at the O or O-27 steel tubular track, doubt starts to seep in – much like the moisture that has rusted the track. An even closer inspection reveals that this track is also very much “used.” Track pins are missing or loose, and rails are misshapen.

Everyone tells you not to bother with the track because you will have nothing but headaches if you use it on your layout. But can it be effectively refurbished?

First, sort through your pile and objectively examine each piece. Don’t waste your time with the pieces that are too far gone. This includes track that is heavily corroded, severely bent, or badly crushed. You can’t save it all.

But if you have track sections that have mild rust, tarnish, or other distortions, you can make them useful again. Here’s my seven-step approach, which applies equally well for O or O-27 track.

Click on any picture for a larger image.

The following tools range from easy to difficult to find. In addition, not all tools of a similar name work for this application. For example, there is an alternative style of hose-clamp pliers that looks quite different and won’t work at all when trying to straighten old track. When in doubt, have a piece of track on hand before you buy any tools in a store. The recommended versions (if any) and tool specifications are listed below.

• Hose-clamp pliers – We recommend a pair made by eHobbyTools.com. Other models may be available in auto parts stores, hardware stores, farm supply stores, and home centers.

• Needlenose pliers – Numerous models, available in hardware stores and home centers. Use a medium-sized tool that fits the track you’re using.

• Diagonal cutting pliers – Numerous models, available in hardware stores and home improvement centers. Size isn’t critical, as long as the jaws fit between the rails. Ehobbytools.com carries a tool called track pliers (no. 10100) that has a crimping nib to tighten pins on Standard gauge, O-27, and O gauge track.

• Abrasive cleaning pads – 3M Scotch-Brite heavy-duty scour pads (recommended), available in many grocery stores, discount department stores, hardware stores, and home centers. Similar brands are available, but never use steel wool instead.

• Lionel replacement track pins – O gauge no. 65551 or O-27 no. 65042, available at toy train hobby dealers.

Remove loose or rusted pins. Good pins should fit tightly and not turn freely in their holes. If you must remove all three pins on a single section of track, put a Magic Marker line on the underside of that end of the track section. This will indicate which end of the section has the factory rail crimps that hold the pins in place. Pull the pins straight out so that you don’t distort the hole. Note the shape of the holes and compare them with properly shaped holes on a new section of track.

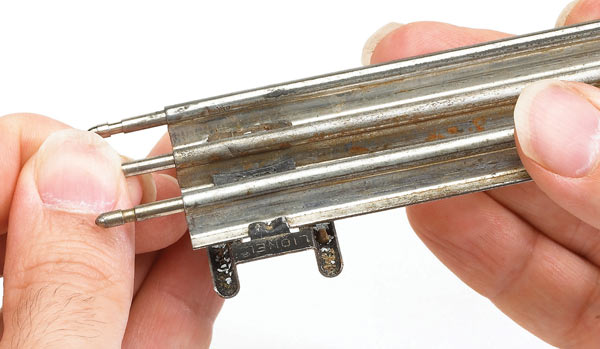

Make sure that the track is straight. In many cases, the track may have a bent end on one or more of the rails, the result of someone pulling the track apart by bending it side to side instead of pulling it straight out. (Note the extreme example on the outside rail above.) If the rail is slightly bent, there’s a tool you can use to straighten it. Hose clamp pliers, typically used for applying Omega-shaped spring wire clamps onto rubber hoses, just happen to work perfectly. (See the “Tools and materials” box on this page.)

The pliers’ jaws has a cavity that, coincidentally, fits nicely around the contour of a tubular rail. The hole in the pliers’ tip allows you to grab the rail on end without crushing the hollow-tube railhead. Just grab the bent rail with the pliers as shown – with the wide-flanged rail base remaining outside the tool’s jaws – and gently bend the rail back into position.

Once the rail ends are straight, you need to restore their contours. Using needlenose pliers, squeeze the middle part of the rail back together as shown. If any of the three tubular railheads is badly misshapen, you’re better off discarding this piece of track than trying to reshape the hole.

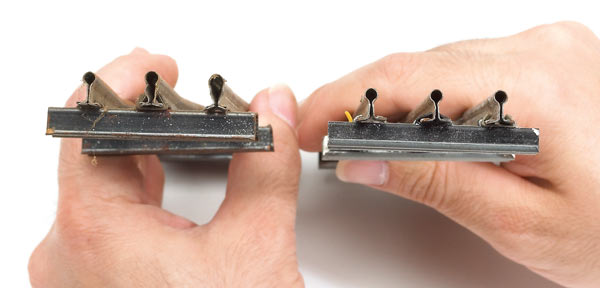

The reshaped rail ends should now look something like this when viewed from the end.

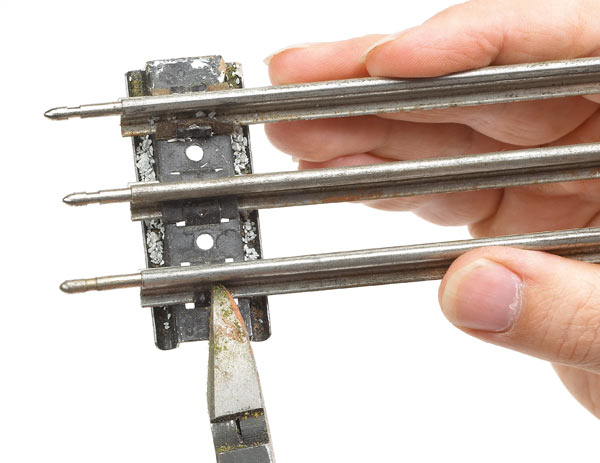

Now you need to crimp both ends of each section of track to properly secure the pins, which should be firmly fastened to keep them from turning in their holes. First, locate the end of the track that has the factory crimps (as you may have marked in Step 1). The factory crimp should be visible on both sides, appearing as small round depressions about 3⁄8 inch from the end of the rail, like the pristine example in this picture.

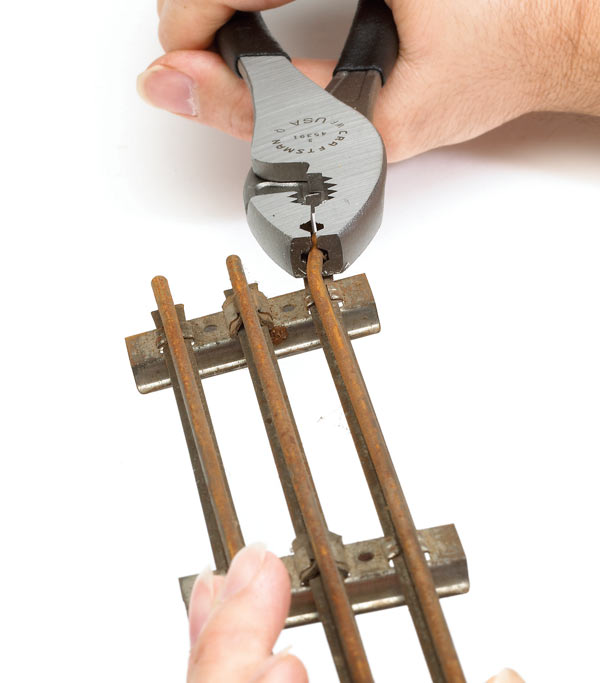

Especially if you had to remove any of the three pins on this end, you’ll need to re-crimp each rail at the same spot as the factory crimp. A good crimping tool is a pair of diagonal cutting pliers – preferably an old pair that is no longer sharp, thus reducing your chances of cutting through the rail. You only need to crimp the rail hard enough to grab a track pin tightly.

The opposite non-pin end of the track needs to be crimped as well. I crimp the opposite end of track about 1⁄4 inch from the end, again using diagonal cutting pliers. You may want to practice crimping some track that you are going to throw away to get a feel for the job.

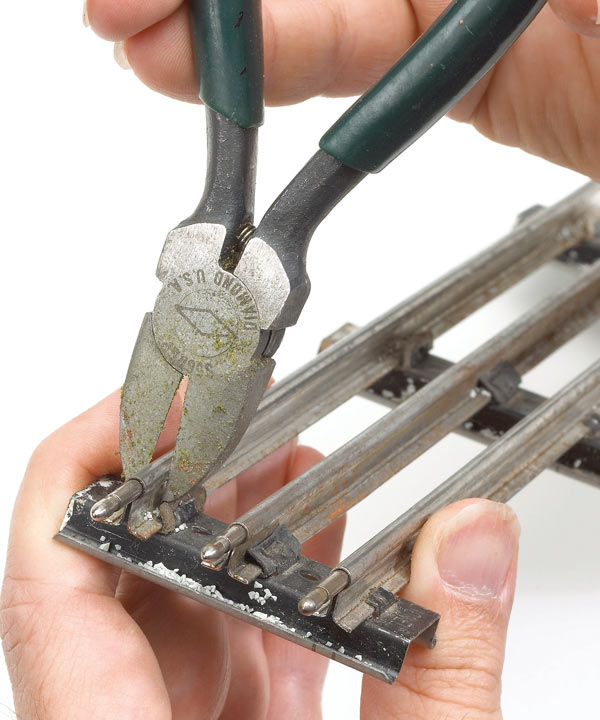

Next, make sure the foot of each rail is tightly fastened to the track ties. The two outer rails again use a factory crimp. For these rails, use your diagonal cutting pliers to squeeze the outside crimp visible on the tie tab that covers the rail base.

To tighten the center rail, use your needlenose pliers to push downward on the paired locking tabs that hold the insulator, rail, and track tie together. Spread the pliers’ jaws far enough to avoid squeezing the rail itself.

You can clean the track in several ways, depending on how much cleaning is necessary. Because some old track has been used on ballasted layouts in the past, you may find a thin layer of white glue hiding beneath the railheads. To remove this glue, use a chisel-type hobby knife blade (as shown here) or bend a thin piece of metal so that you can easily reach under the railhead. The glue should pop off the metal as you lightly wedge the blade into the glue joint.

Next, clean the surface rust from the rails using a cleaning pad and some soapy water. Since the track is zinc plated to protect the steel rail from corrosion, you don’t want to remove any more plating than is already worn off. Scotch-Brite pads (made by 3M) strike a good compromise in providing enough abrasion to quickly remove surface rust without scratching the metal. Don’t use steel wool, which, besides being more abrasive, can leave residue strands that could end up inside locomotive mechanisms.

To prevent rust from re-forming, immediately dry your freshly cleaned track with a towel and bake it in an oven at 200 degrees for an hour or so.

Finally, inspect the track pins. If they aren’t too badly corroded, clean any visible rust using Scotch-Brite pads and water. You can simply hold the pin with a pair of pliers while you’re cleaning it (a slower, safer method), or you can put each pin in a drill chuck and apply power while keeping the cleaning pad wrapped around the pin.

If a pin is badly corroded, replace it with a new one. In either case, reinstall pins by tapping them into place – if the pins can be easily pushed in with your fingers, the crimps you made earlier aren’t deep enough. You’ll need to re-crimp, as described in Step 4. After tapping them in place, try to turn the pins with your fingers. They shouldn’t spin at all.

After all your work, it would be a shame if you let your track sections deteriorate again. There are several things you can do to prevent track problems.

First, if you plan on storing your refurbished track for a while, I recommend that you wipe the tracks down with lightweight machine oil, like 3-in-1 Oil or sewing machine oil. The oil provides a protective coating against rust. After installing your track, you can clean the railheads with alcohol or a track cleaning lubricant.

Don’t keep the track in plastic bags, which can trap moisture. Obviously, keep the track out of damp areas, such as your basement, or you’ll probably be doing some more refurbishing.

When you’re ready to install the track, clean the old oil off the railheads and anyplace where you may need to make a solder connection. Then, before permanently installing any of the pieces, absolutely test the track to make sure the center-rail insulation that prevents shorts is still viable. You may want to press down on the center rail a bit to mimic the weight of a passing train, just to make sure.

It’s certainly possible, even after all your hard work, that a few pieces of refurbished track will never make it to your layout. But I’m sure you’ll be happier safe than sorry. And you still can’t beat the price.

I have used Lionel tubular track, and Fast track;

the fastrack electrical connections are not the best, and loss of power thru switches is annoying;

I also have the old Super O, Lionel 57-66;

thinking of having the curves re bent to 072, it looks great, built strong. the quality of the Super of was excellent. 100% better than the Fast Track quality.

the problem with super O is that the switches are only 036, so Atlas or ross switches would be better.

actually too bad Lionel didn’t bring back super O in the 90’s, before the fast track, and offer 072 curves, and new switches , with many curve ratios, like they did do with Fast track.

but now it’s doughtful that they will do this, sine the adult market is flooded with many track choices.

maybe an outside frim will buy the rights for super O , and make it in China, like everything else.

I made a decision to get rid of tubular track and go with Gargraves. You can make your own curves and the track is much more realistic looking( even with that black center rail) then tubular. Plenty of deals on Gargraves on Ebay. My turnouts are a combination of Gargraves and Ross. Both can be made non-derailing, just like Lionel’s, though all of mine are controlled by Tortoise switch machines. I did not upgrade to the new train control methods; I’m still using Lionel Z type transformers so learn how to run at a slower speed. Nothing requires the full 25 volt output

Very good ideas. I used old tinplate .027 track on my layout and it saved me A LOT of money. Of course, it took some time and patience to clean it, but it was worth all the effort. Incidentally, Marx and Lionel curves and straight sections of track are quite compatible with each other without any modifications to either brand. You could however swap out the track pins so that they are all the same, but it is not necessary Marx pins are strait with no indentations and may come out more easily, while Lionel’s are indented, and may hold more firmly. It’s just a mater of your own personal preference. Remember, applying a little elbow grease and some work brings its own rewards! A great looking, smooth running layout!

Menards has a pretty full line of tubular track at good prices. Williams offers a limited selection. If your track is badly oxidized (the zinc plating has turned dark. but is not rusty) try painting it with Rustoleum brown primer or Krylon Super Flat Camo “dark earth” color.

In trying to refurbish some 1950’s era O-guage tracks I found that the only commercially available track pins are 7/64″ in diameter. These are too tight for these old tracks which have a 6/64″ (3/32″) diameter. The solution is get 3/32″ copper or aluminum rods (readily available on AMAZON). Hope this info will help someone.

I've used ScotchBrite to clean the outside of the track, but rust still forms on the inside of the tubular rail (Especially if the old pin is rusty when you remove it). I use a variable speed drill and a bit that just fits inside the tubular rail. I put the track in a vice (to securely hold it so it does not catch and spin when drilling) and use the variable speed hand drill with properly sized bit to ream a clean hole to accept good track pins. You will be amazed at the crud you will find on the bit!

I also have the track pliers tool that can reform the tubular rail if the reaming process makes it to big. Don't ream to much, just enough to remove the rust and crud inside. And remember to re-crimp the section holding the pin.

Have cleaned many of old track they still work well thanks for all the tips I will try then out

Fastrack is great looking and well engineered but I found it to be very noisy compared to tubular O gauge track

hi guys im sorry this is not a comment but a question since we are on the subject of old track. I really like the lionel ogauge track(was what I had in my younger days) Fastrack is nice but to me on some pieces very pricy.

I hope someone knows if Lionel is going to keep on making tubular track for us traditional kind of folk. Thanks for any responce

I hope thaiiii

try metal rescue you can purchase this from menards get a plastic conainer that fits the track that you are restoring pour the liquid into the container enough to cover the track let it soak for 30 minutes and rinse of with water and dry with a clean towel paper or cloth your choise dry out in oved.works great for me

while all this stiff works a dremel tool and several polishing wheels will usually get everything off short of total corrosion and polish it up nicely cant rember the number dremel uses but its the 2 color pack and with a bit of practace can be used 4 several pieces of track

Hair Clipper oil, found at Beauty Supply shops or on line is another alternative to 3-1-oil. A bitt cheaper in the long run.

Some Lionel veterans report that the company strongly advised against "3 In One." I'm new here and claim no expertise.

Used many of these tips on my 0 & 027 track I also use the pointy end of a dart just take off the tail end and tap in dart to open holes works great for me.

"To prevent rust from re-forming, immediately dry your freshly cleaned track with a towel and bake it in an oven at 200 degrees for an hour or so"

This is a copy-paste part of the article.

I do not understand why baking the track will prevent rust re-forming.

This article was very useful for me.

Thank you very much.

Great article!!

I am currently repairing track and switches to build a pre-war layout.

Some of the track and pre-war switches I have are in really bad shape and Mr. Kelly is correct about the overpricing of some Lionel items on ebay.

A great place to pick up older track is train shows (look under the tables).

I also loved the information from fellow collector Mr. Vibert, I will give his system try as well.

Great article, in future would like to see an article on recycling lionel super O

track. Tips and tricks about making the track look new. I am in the process of making a new layout with the super O track.

Good article. But I prefer to restore Super-O track.

soak the track in evaporust or crudcutter after a couple of hours it will be like new

This will work if you can get track at little or no cost. Buying used Lionel track on e-bay is iffy at best and sellers think track is Gold because it says Lionel USA. Add shipping and track costs more than new. Go with Fastrack; for the price and convienience you cant beat it and you can use previously published track plans for tubeular track with little modification!

I guess I am lucky I have a glass bead blaster and I use this for cleaning. Then a light spray of wd-40. The other tools as needed

as a disabled person i have even less money than most 4 the hobby a dremel tool with abrasive wheels allow u to polish the rails almost perfect an extra step is to completly take the track apart so u can get at all spots on the rail however in most cases u can return a tarnished piece to almost new looking just do 1 rail at a time

Thanks KarenI for the food saver bag idea. I will give it a try.

I also like the hose clamp pliers for reshaping the end rails.

Thanks everyone

s amatter of fact it looked great with the rust below the restored railheads.

TIGHTENING CENTER RAILS?

Here's a suggestion. From a piece of scrap 1/4" or 3/8" plywood, cut a piece approximately three or four inches by slightly less than the width of your track's ties. Clamp the piece of plywood in a bench vice so that an inch is sticking up above the jaws of the vise. Place each tie over the piece of plywood so that when you're pushing down on the tabs with the needle-nose pliers, you'll have an 'anvil' to press against. That way you won't accidentally bend the rail flange and / or bend the tie slightly concave from the downward pressure.

The part about "slightly less than the width of the tie" has to do with "0-27" track, where there's sheet metal bent down on each end of the tie. "0" gauge ties are open-ended, so that problem doesn't exist.

Don't forget to check to see that the fiber insulating piece is in position, and intact!

Good luck!