Editor’s note: Kirk Lindvig reached out to Classic Toy Trains offering to send product samples for review. When he emailed photos of his U.S.-based manufacturing process, it reminded me of the behind-the-scenes manufacturer profiles CTT used to do years ago. I felt our readers would find the process interesting. I present this Q&A interview with co-owners Kirk and Chris Bogus, and hope you find it as fascinating as I did.

Q: How did USA Track LLC get its start?

A: My friend Jim Kelly-Evans and I founded the Standard Gauge Module Association (www.sgma.us) in 2006 to commemorate the introduction of standard gauge by Lionel in 1906. The club originally focused on providing big layouts for large train shows like The World’s Greatest Hobby on Tour. But since the COVID-19 pandemic, we’ve concentrated on smaller events like Trainfest, Trainfair, the TCA York meet, and our annual Christmas show at the Winterthur Museum in Delaware.

When I discovered MTH was going to source their standard gauge track from China, I partnered with SGMA member Chris Bogus to start USA Track LLC. We wanted to make sure club members and other enthusiasts would have quality track for building club modules and home layouts. In 2024, we’re celebrating our 15th year in business.

Q: Who owns the company?

A: Kirk Lindvig and Chris Bogus.

USA Track is a “labor of love,” with all proceeds being redirected into preserving and improving the original tooling and materials. Neither Chris nor I have taken any compensation for our work.

Q: Tell us about your manufacturing process.

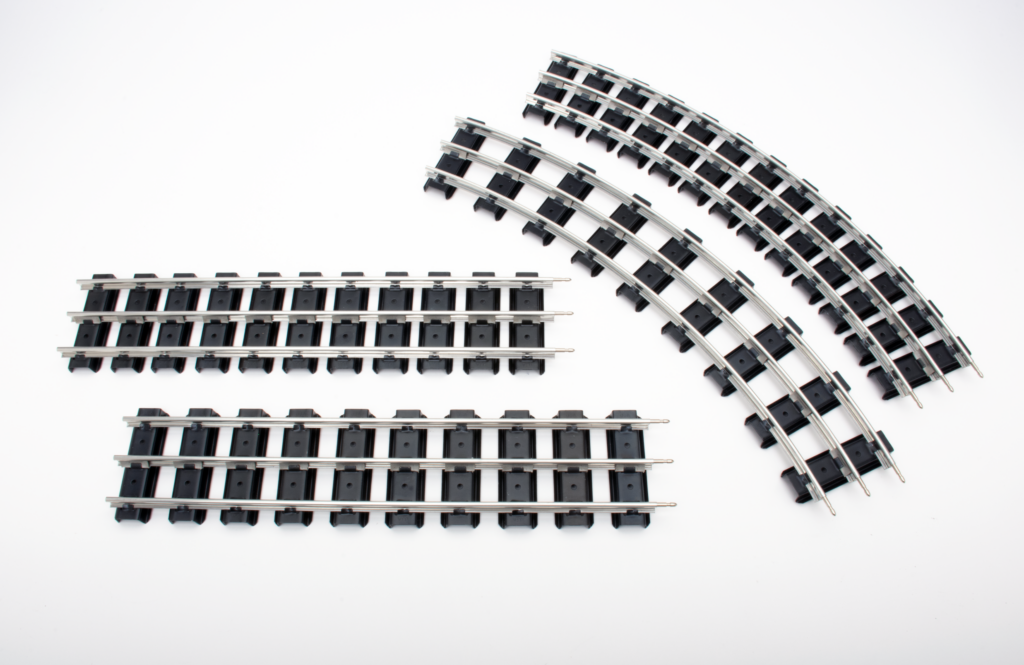

A: Starting with tooling originally made by Andy Kriswalus (KMT) during the 1970s, USA Track has expanded standard gauge track offerings to include four diameters of curved track and four standard lengths of straight track. All are compatible with vintage track and the Ross Custom Switches standard gauge products, and are now available with optional extra ties for an enhanced appearance.

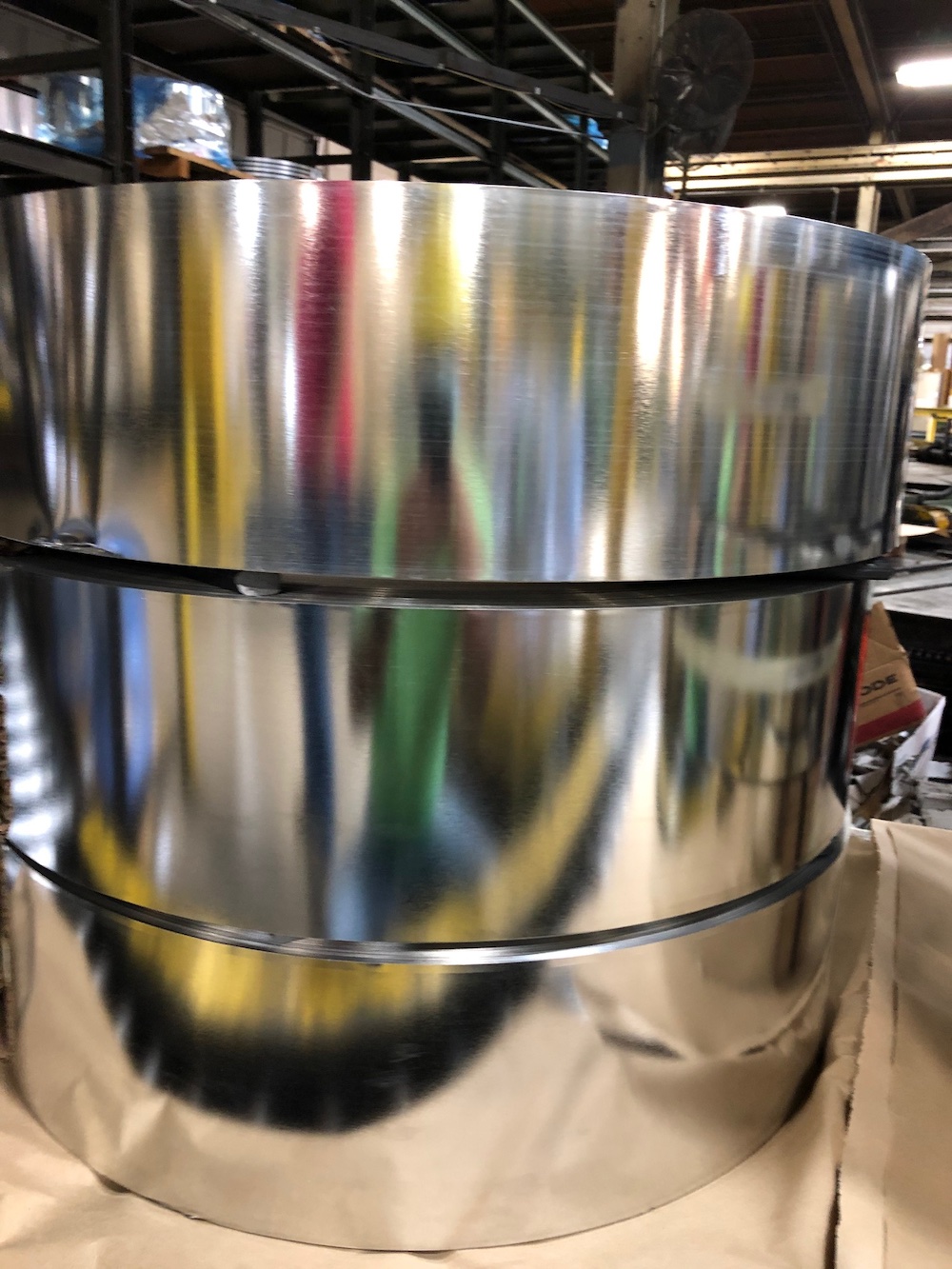

The quality of the track is unmatched. All of the component parts are made in the U.S., and the quality of the materials has been improved at every opportunity. During the past year, we have rolled over 200,000 feet of the best tinplated steel available to make rails.

Precision track pins are individually lathe turned (+/- 0.001″), and then nickel plated. Heavy gauge steel is cut and stamped into metal ties. which are given a traditional black oxide finish and protective oil coating. The fiber insulators placed between the rails and ties are uniquely robust and resistant to failure.

All of the original Kriswalus tooling has been upgraded and improved. We carefully monitor the offsite production of the component parts using this tooling (in New York and New Jersey), and then transport the tooling and parts back to our new assembly shop outside of West Chester, Pa., where all fabrication occurs — both for standard sections and custom pieces.

Q: What’s different about your track compared to other brands?

A: Our goal is to make this track the best it can be, and optimized for hobbyists who are building permanent layouts. For this reason, unlike original Lionel track, the ties have a single crimp attaching them to the rails so they can be moved without damaging the rails. Also, the track pins are 0.005″ oversized, which sounds trivial, but makes for a great mechanical and electrical connection (The downside is that disassembling the track requires a bit of care).

Vintage Lionel track is better for temporary layouts, but I don’t think there’s a better track than USA Track for permanent installations.

Q: Does your track work with vintage Lionel or MTH Standard gauge track brands?

A: Our track is fully compatible with all traditional tinplate tubular vintage track, reproductions of vintage track, and the Standard gauge switches made by Ross Custom Switches. It can not be directly connected to GarGraves track or plastic roadbed MTH track.

Q: How can hobbyists buy your products?

A: To maintain the lowest prices, we only sell direct to consumers. We can be reached at standardgaugetrack@gmail.com.

Q: What’s next for USA Track?

A: USA Track has always been willing to work with Standard gauge enthusiasts to meet special needs. Dual gauge (Standard/O) is becoming popular. And in addition to providing parts for those building their own, we plan to offer dual-gauge track in 2025. We would also like to help our customers by making ultra-wide curves, by offering a “flex-rail” system of tinplate tubular track.

Contact USA Track

https://standardgaugetrack.com

Tips for using USA Track

Where possible, to connect track sections, we like to use the “tap” method: First align the track pins of one section with the rail openings of the next, then tap on the other end to bring the sections together.

Obviously, this method won’t work when “closing the loop.” In this case, “stretching” the rail openings a bit before trying to insert the track pins helps.

Alternatively, you can insert a thin-bladed tool into the bottom of the rails to open the spring.

If you need to remove a track pin, tap it IN slightly before pulling it OUT. This releases the dimple in the rail that locks into the groove in the track pin.

Never use abrasive cleaning methods on tinplated track!