How much better is the newest QSI locomotive sound board? Let’s count the ways, or better, let the sound board itself do the counting!

First, QS-3000 has taken a big step forward in special effects with a long list of new sound features. On the list are a run-by sound pitch shift (very neat!), atmospheric variations, coupler slack sounds, emergency stop sounds, additional neutral sounds, soft and hard steam chuffing, and diesel turbochargers. Also impressive is the greater flexibility with passenger and freight announcement sequences.

Second, QSI has improved the method to turn features on and off or modify them to suit your taste. With locomotives featuring older QSI sound and control boards or MTH ProtoSound, anyone wanting to alter the passenger/freight announcements had to raise and lower the track voltage 28 times to access feature no. 28, which is passenger or freight announcements. Unless you have an MTH Z-4000 transformer (which has a programming feature that does the counting and voltage manipulation for you), reaching level 28 involves keeping count of a series of xylophone-like clinks and clanks as if they were Roman numerals – five clinks equals one clank.

Thus, Level 28 is five clanks and three clinks. Not very user friendly.

With QS-3000 the destination is still the same, but the trip is easier. The QS-3000 board verbally announces the programming level you are on as you move the throttle arm back and forth. At level 28 you hear a voice telling you “28, passenger/freight announcements. Dispatch, I’m ready.” Much more user friendly.

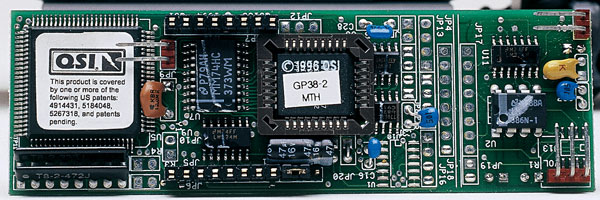

We put a QS-3000 board into an MTH ProtoSound-equipped GP38-2 and asked TrainAmerica Studios to install a QS-3000 board into an MTH RailKing Camelback locomotive converted to command control with a UCUB.

It took barely five minutes to swap the ProtoSound board for the QS-3000 board in the MTH GP38-2. The swap involved removing the locomotive shell, disconnecting plugs for the volume control switch and the speaker, gently prying off the ProtoSound board, and replacing it with the QS-3000 board and reconnecting the plugs.

Once back on the track, the QS-3000 Geep’s diesel motor sounds are richer, although only in a side-by-side comparison with a ProtoSound locomotive are the differences truly apparent. Start-up sounds are clear and accurate, and, when the engine is in neutral, four quick blasts of the horn initiate a shut-down sequence, complete with crewmember voices calling to one another. Other sounds in neutral, triggered by a Morse code of short and long horn blasts, are fueling, maintenance work, and water filling.

The best effect is the “Doppler-shift” horn. Who hasn’t, as a child (and an adult), mimicked the honk-honk-hooooooonk of a diesel engine roaring past. By holding down the horn button for three or more seconds, letting up on the button briefly before the horn sound ceases and then again pressing the button, you achieve the “hoooooonk” part of the effect. Cool!

The enhancements to our Camelback steamer were more pronounced, since a steam locomotive has a more distinct repertoire. Chuffing is good in both rate and tone, although things get busy-sounding at higher speeds and the chuff lacks the thump-thump bass tones of a competitive sound system.

In command mode, the neutral sounds previously lost in the UCUB-ProtoSound conversions are heartily welcomed back. ProtoSound systems must be locked in forward for the command conversion, cutting access to all neutral sounds; the QS-3000 board creates a “neutral sound state” by sensing a lack of current going to the motor when the locomotive is stationary.

The neutral sounds were better than those of the diesel, especially the water-filling sound, which, besides the chatter of the crew members, includes the groaning of a water spout being swung and lowered into position (this would be perfect with an operating water tower). The Doppler effect of the whistle, while not as obvious as a diesel horn, was pleasing nonetheless. Our Jersey Central Camelback sound board included an authentically accented passenger announcement for Jersey City. The accent is right on (my aunt lives in Bayonne, N.J., so I know).

There are still some compromises in the QS-3000-UCUB combination, most notably when the locomotive is asked to operate in conventional mode, where there is a threshold of 10-12 volts for the sound system to kick in. Few users, however, will be regularly running a QS-3000-UCUB in conventional mode.

Overall, the QS-3000-UCUB combination is far, far more satisfying than straight ProtoSound-UCUB conversions. One drawback: to program QS-3000 sounds on a UCUB locomotive, you’ll need a transformer with a throttle handle to manipulate track voltage in order to gain access to programming levels; Lionel’s PowerHouse-CAB 1 combo alone won’t work.

The QS-3000 comes with numerous pieces of paperwork covering installation, applications, warranty, and features, including a nifty spiral-bound “quick-start” guide. Our installation instructions, two pages printed on both sides, were mismatched, and it took a few moments to figure out that page 3 should actually have been page 2. If you’re new to QSI sound and control systems, you absolutely want to telephone QSI to request the free QS-3000 users guide or download it from QSI’s web site. The booklet, at a hefty 150 pages, covers everything you’ll ever need to know. Its thoroughness and organization are a model other manufacturers should follow. QSI warns users that its sound board is not approved for use with the MRC O27 and MTH Z-750 transformers and that the QSI PowerGuard should be used to suppress spikes that could damage the sound system.

QSI offers information on modifying the boards to prevent erratic performance with MRC transformers. During our testing we did not encounter any problems using a Z-4000 transformer and a combination of Lionel TrainMaster and IC Controls components, neither with a spike-suppression device.

Sound systems and upgrades aren’t cheap, but if toy train bells and whistles are music to your ears, the QS-3000 is worth raiding your piggy bank.