Sound system? Yes.

Command control? Yes.

Coil coupler? Yes.

Cruise control? No.

Fan-driven synchronized puffing smoke? No.

Train America Studios can turn no into yes with its Engineer-On-Board cruise control and its Turbo Smoke smoke generator.

We had both installed in a K-Line scale Hudson (the same Hudson we reviewed in the July 2003 issue) to get a better grasp on how these two new aftermarket devices work. Although we chose a steam locomotive, both Turbo Smoke and Engineer-On-Board work equally well in a diesel or an electric-profile locomotive (you’ll have to justify to yourself why your electric smokes).

The hardware

Turbo Smoke is aptly named. The replacement smoke unit features a two-speed fan. When a locomotive is stationary, the fan runs at low speed to simulate a diesel exhaust at idle or a steam locomotive at rest. Once the locomotive is under way, the fan kicks into high speed continuously for diesels and on and off in synchronization with the chuff sounds for steam locomotives.

Turbo Smoke also has a self-protection feature. If you run out of smoke fluid but forget to turn off the smoke unit, it turns off power to the element to prevent overheating and uses the fan automatically to keep things cool.

Engineer-On-Board is Train America Studios’ response to Lionel’s Odyssey speed control and MTH’s Proto-Speed, part of its ProtoSound 2.0 package and also a feature on RailKing LocoSound-equipped locomotives. Atlas O, K-Line, Weaver, and Williams do not currently offer cruise control; 3rd Rail uses Engineer-On-Board in its latest locomotives.

All three of the speed-control devices rely on sensors that read the rpm of a locomotive’s flywheel.

The sensor sends data to the locomotive’s circuitry, which adjusts voltage to the motor or motors to keep the locomotive moving at the same speed, regardless of the track grade or the load the locomotive is pulling.

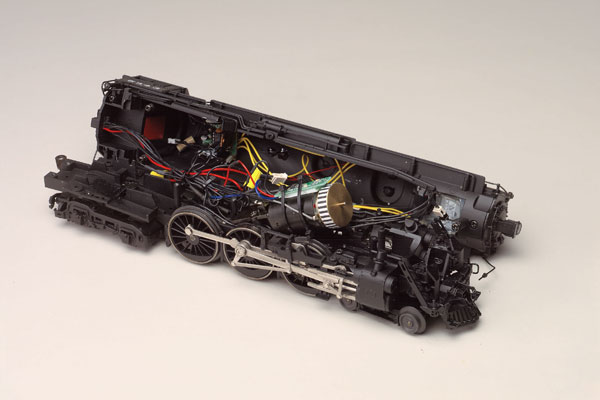

Our K-Line Hudson now wears a black-and-white tape strip on its flywheel and sports a sensor and a small circuit board affixed to the side of its motor.

The sensor isn’t all that’s new on the locomotive. The Hudson has a new Train America Studios “motherboard” to process the rpm data, replacing the original Lionel TrainMaster Command Control board inside the Hudson’s tender. Also, the entire tender shell is now the TMCC antenna, so the shell is insulated with electrical tape and nylon screws from the tender frame.

The new board in the tender and a new sensor and smoke unit in the locomotive necessitated a new eight-wire tether between the locomotive and tender. The new tether is a bit bulky on our Hudson and visually more distracting than the original K-Line tether.

Both the Turbo Smoke unit and Engineer-On-Board are offered as self-installation kits, or you can send your locomotive to Train America Studios, where technicians will install the components for a reasonable fee. Since our Hudson was getting the works, we decide to let Train America Studios do the installation.

We recommend that you have a very good comfort level with toy train electronics before tackling a home installation of Engineer On Board, especially in a steam locomotive.

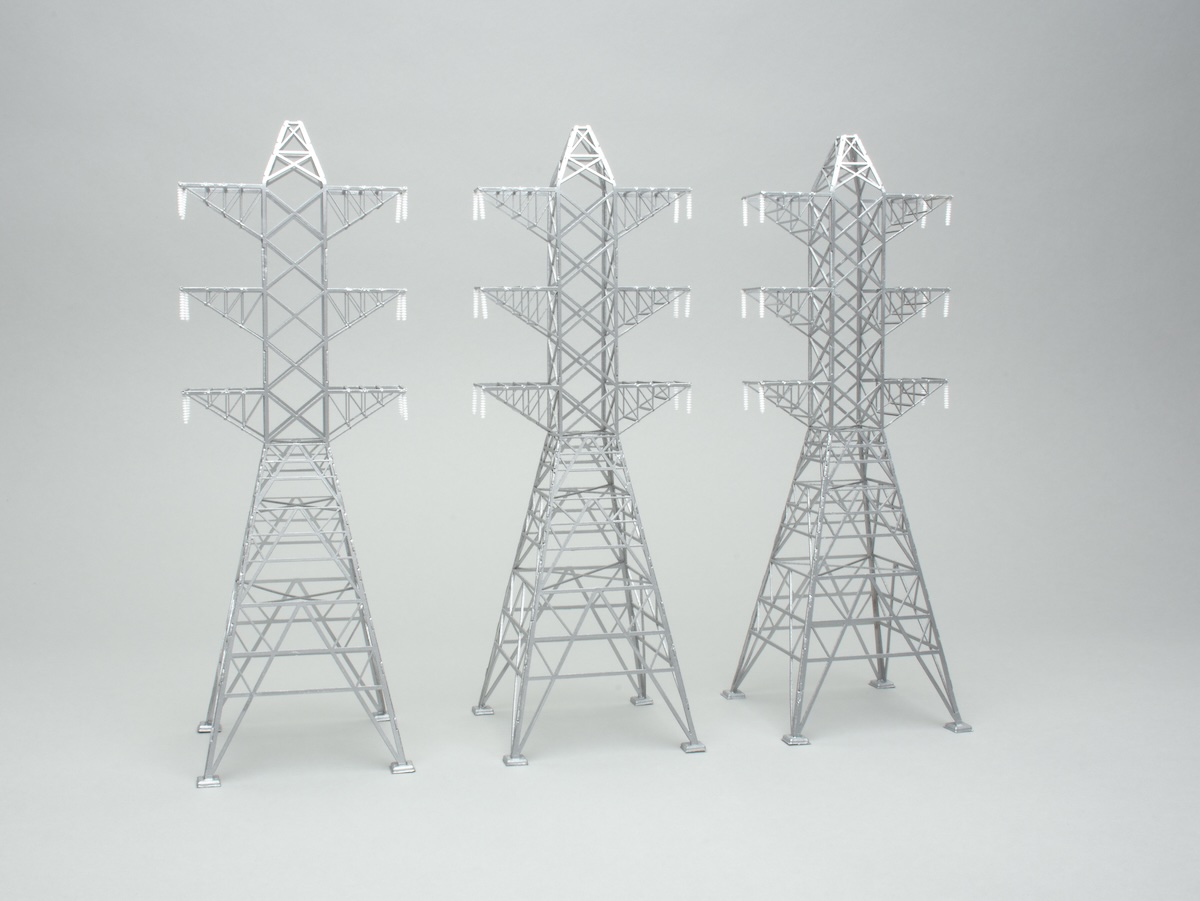

Not every locomotive is a candidate for Turbo Smoke or Engineer-On-Board. The Turbo Smoke unit is 21/2 inches long, 1 inch wide, and 13/4 inches tall, so it won’t fit in every O gauge diesel or steam locomotive. It doesn’t need to be in a locomotive to operate, so it could also be installed in a factory smokestack or a “burning” building on your layout.

Engineer-On-Board requires a can-style motor equipped with a flywheel (no Pullmors) and enough space inside a locomotive’s shell to fit the sensor. There also must be space in the shell or in the tender for a new “motherboard.” Locomotives already equipped with TMCC are the easiest candidates.

On the test track

Our Hudson already had a healthy smoke unit from K-Line, but Turbo Smoke raises toy train smoke to a new level.

At rest in TrainMaster Command Control mode, a steady stream of smoke rose from our Hudson’s stack. With a fractional turn of the CAB-1 controller, the smoke level increased and stopped – then burst out of the stack a good 5 inches upward in sync with the locomotive’s RailSounds and the movement of its drivers.

As the locomotive accelerated, the bursts merged into a steady stream of smoke, filling the room with haze after three circuits of the layout. The effect was just as appealing when we ran the Hudson in conventional-control mode.

Engineer-On-Board lived up to its billing. Our Hudson could be slowed to a crawl, and our previously recorded low speed of 9.8 scale mph dropped below 5 scale mph with the new circuitry installed. The locomotive didn’t stall while pulling heavy trains up and down grades and around tight curves.

In both command-control and conventional-control modes, there is no need to “select” a speed. The cruise control simply functions at the throttle setting.

Engineer-On-Board also offers benefits beyond just speed control. In command-control mode it offers the option of switching between 32 TMCC speed steps or 128 TMCC speed steps on the fly. You also can change the RailSounds chuff rate to one, two, or four per revolution of the drivers. (Actual locomotives are four; most toy train locomotives, which are traditionally operated at higher scale speeds, are two.)

Both the speed step and chuff rate changes are made through a series of CAB-1 commands (for example, ENG, number, AUX1, AUX1, and 5 will cycle the chuff rate between one, two, and four chuffs per revolution). Engineer-On-Board can be turned off at any time.

Although we’ve had our newly enhanced Hudson for only a few weeks, we’ve been running the pants off it. So far the Turbo Smoke unit and Engineer-On-Board circuitry have held up fine, and we’re pleased with our high-tech steamer.

If your locomotive’s checklist lacks speed control and fan-synchronized smoke, give Train America Studios a call.

Gonna have to consider this for the Union Project.

What happed to TAS??