Craig Lund

Denver, Colorado

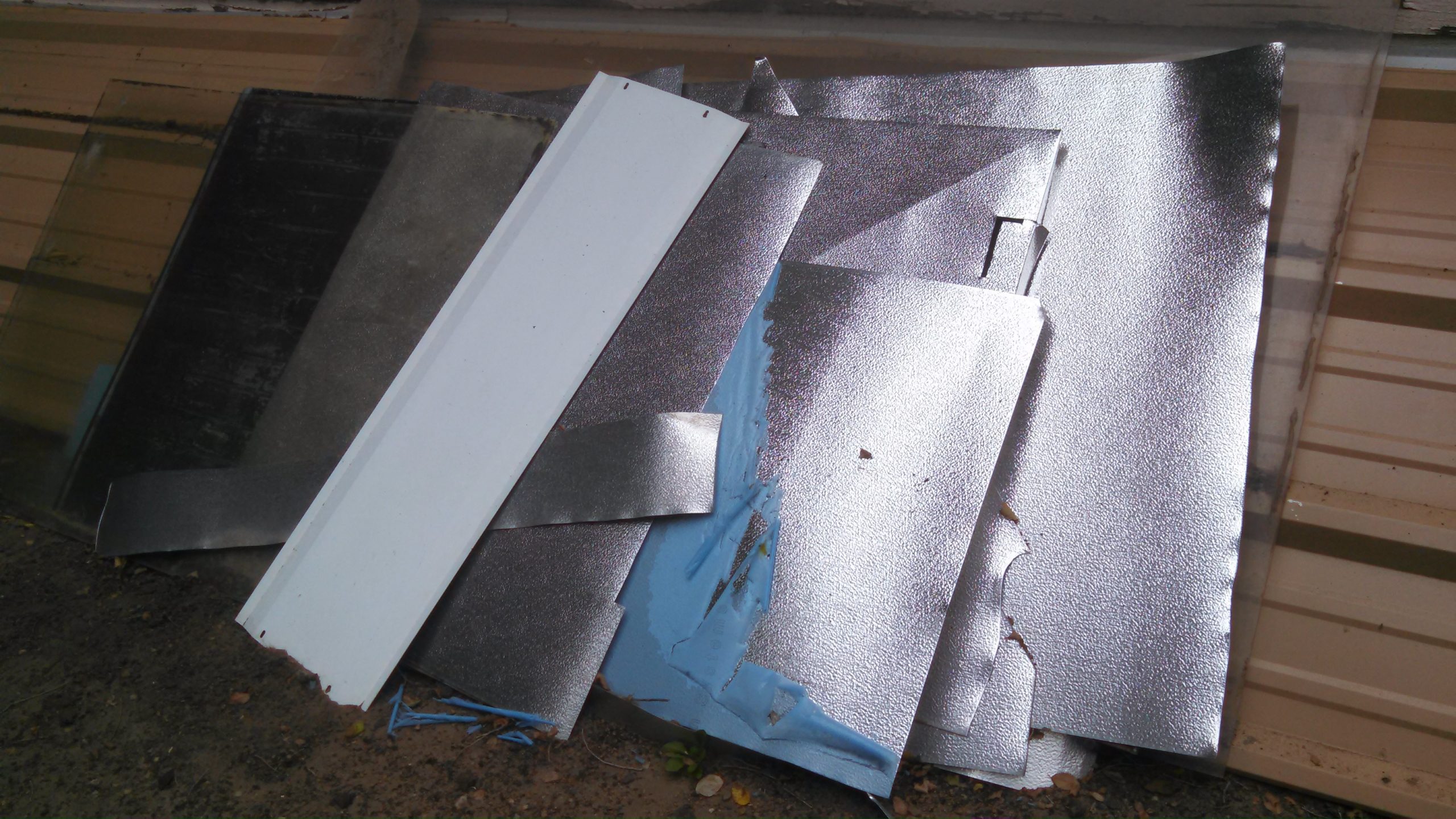

Recycled metal

I like to use “used” items in my railroad. The light fixture was purchased for $5 at a garage sale. It was a standard two-bulb fixture with all the guts removed. The project manager at a construction site gave me the other metal pieces. Both sources are good for clean, low-cost material. I used all metal in the construction. Wood can be used but tends to warp and rot. My shed is over-built but will last 100 years. I simply built a metal frame out of perforated angle at the base, and steel 6″ x1.5″ studs for the sides and ends. This frame gave me something to which I could screw and rivet the outer skin.

I have a small sheet-metal brake and shear, which allowed me to bend the outer panels, giving them a nice architectural appearance. The inside is unfinished. I am only concerned about the outer appearance. The scaled size came from a real railroad shop in which I happen to work. I use 1:24 scale because its easy to work with and close enough to the 1:29 and 1:22.5. The entry doorways are 3.5″ tall, which is 7 feet in scale. The bay doorways are 10″, which is 20 feet in scale. The SD-70 in the video is 16 feet tall in real life. The height above the doorways is to give the illusion of an overhead crane inside, which all heavy repair shops would have.

The concrete slab on which the structure sits is monolithic and took five bags of mix to make it. It was made upside down, with strips of wood nailed to the base wood. When it was flipped over, the base wood and strips were removed, leaving a nicely finished surface with built in track grooves. It’s too heavy to move, so it was made next to where it would be placed when it was flipped over. The shed is 2′ x 4′ x 2′ tall. The pad is 28″ x 6′. I estimate my project cost to be around $50. Want more parking space? Use a four- or eight-bulb fluorescent light fixture.

My daughter put together a video that showcases the engine shed rather well on our Boxwood Scenic Route Railroad.

This is an outstanding layout. However, the video is one of the best train videos I have ever seen. The camera gets right down on the ground level. I have always thought that is the best way to photograph our railroads. The music is stunning. I had to research who that was, and have already ordered the CD from Amazon. That is a very professional job.

Thanks for the layout as well as the music.

Paul