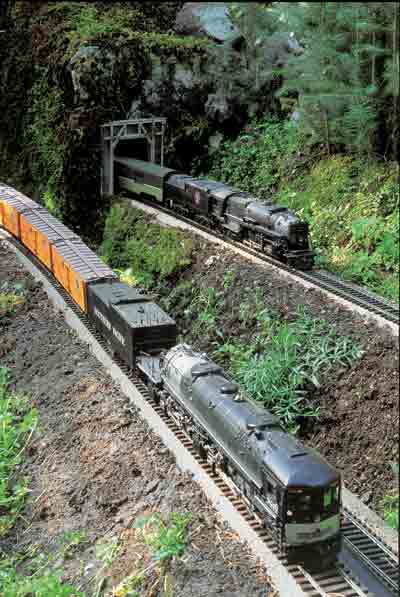

As a teenager, I was spellbound by the articles that Frank Ellison wrote about his 0-scale model railroad and, when I retired 13 years ago, I discovered with amazement Garden Railways magazine and the concept of garden railroads. I immediately decided to combine those two passions, where my overriding goal was to have 0-scale trains running through natural scenery, including real soil, big rocks, miniature plants, and so forth. I wanted to use the native fir and cedar forest adjacent to my layout site as the backdrop. My railroad would be on Vancouver Island in British Columbia, adjacent to a natural lake, and in a place where a northwest coastal climate dominates.

I ultimately selected the steam-to-diesel transition era as my specialty and, over the next eight years, I diligently acquired a good size collection of two rail, 0 scale, brass steam and diesel locomotives and cabooses, as well as over 100 freight and passenger cars. I found Southern Pacific (SP) and Great Northern (GN) steam engines with Vanderbilt tenders to be the models I liked best, as well as being the most available.

I started serious work on my railroad five years ago and chose a design whereby the trains run at chest height for realistic viewing. I was partially inspired by Jack Ray’s famous English 0 scale, garden shelf railroad, Crewchester, described in a series of four issues of Garden Railways in 1988. I was also influenced by the author’s clever line, “. . .maintenance done with one’s head between one’s knees tends to lose some of the glamour as the years advance.”

My original idea was to have only train storage indoors, with mainlines and small towns outdoors. But 0-scale brass locomotives are both heavy and delicate, so I decided to adopt the philosophy of never touching the locomotives and rolling stock, but to have all trains made up by switching operations. This decision led to the design of an indoor train-storage area that was similar to a conventional railroad division point, including a turntable with locomotive-storage leads and freight and passenger yards. Having gone that far, I decided to go ahead and design the indoor portion as an actual division point, with the idea that I would eventually add a passenger station, industry sidings, some industrial backdrop buildings, and other appropriate scenery, although I rated this as a lower priority.

I decided my railroad would be the mythical Oregon Division of the SP, located on the east side of the Cascade mountains and running generally north and south, with a wholly owned branch line named the Cascade Pacific. A few GN and NP trains would run to or through the division point. For serious operators, I wanted point-to-point operation, with trains originating in the south and passing through to the north, and vice-versa. I wanted major action at the division point and switching action at each town.

For visitors, a requirement was to have at least three trains running at once. After building and operating the initial single-loop phase, I realized I wanted to have as many as eight complete trains assembled and ready to run at the start of a visitor session, including possibly four passenger, two long freight trains, and two shorter freights.

I wanted radio control (R/C) for all locomotive cabs, since the trains are usually out of sight of the power packs, and I wanted visiting children to be able to operate at least some of the trains and the turntable. I also decided that realistic sound for all operating locomotives was desirable and that the sound system should allow children to at least operate the bells and whistles.

Planning

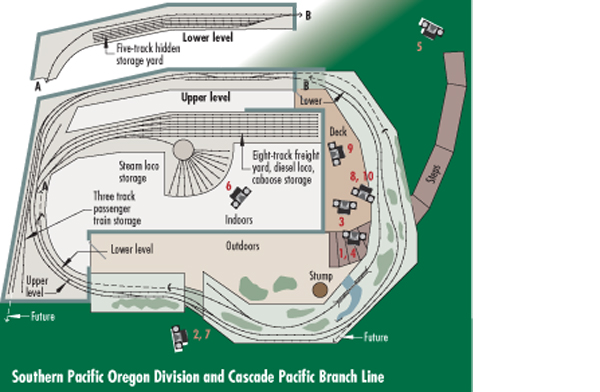

I designed a two-level, three loop, single-track mainline, with a hidden, indoor storage yard on the lower level to store trains passing to the north from the south (and vice versa) and to store five extra trains for continuous operation on visitor days. The length of the mainline was to be approximately 330′. The division freight and passenger yards, turntable and steam storage leads, and diesel and caboose storage tracks were to be indoors on the upper level, with a ramp and small test loop on the lower level (also indoors) for winter testing of trains. The mainline minimum radius was to be 84″, with no yard radius less than 63″. Grades would be 2% or less.

An existing 12′ x 15′ work shed was to be expanded to 22′ x 30′ for the indoor, division-point portion of the railroad, including a new roof and installation of double-pane windows, insulation, and propane heat. The total railroad size was determined to be 30′ x 44′, with a major part of the outdoor portion passing over a fairly steep downhill grade, requiring a strong and well-braced substructure.

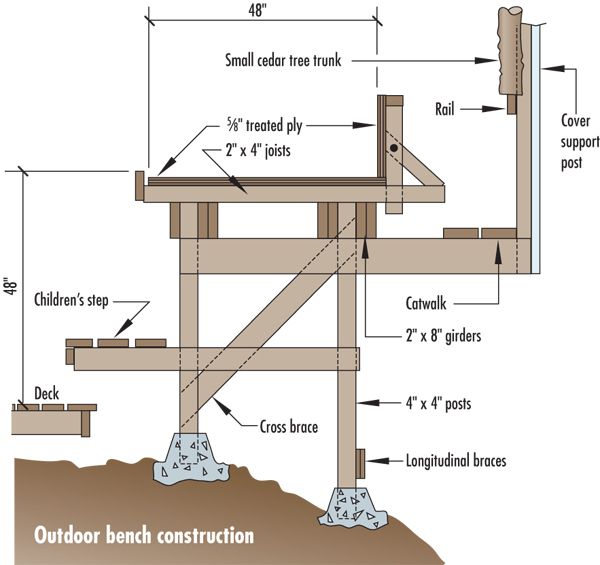

A 4′-wide shelf was selected as the basic building block for outdoor trackage, to allow room for plenty of natural scenery, with access to both sides via decking on the inside of the platform and catwalks where necessary on the outside. Tunnels were to be completely accessible from the catwalk. Full-height access to the line would be available via steps under the shelf at the point of maximum downhill grade.

The shelf substructure was designed to be strong enough to support a two-foot depth of saturated soil, heavy rocks (head size), and wet snow. I was attracted to the idea of building at least part of the shelf on a solid-soil rockery, as Jack Ray did with Crewchester, but I decided that terrain problems, in combination with the requirement to import and compact tons of soil and to build retaining walls, precluded this approach.

A natural consequence of the indoor/outdoor design was that the shed walls create view blocks, so that only linear portions of the railroad could be viewed from any location, which disguises the loop.

Through-the-rails sound was selected for its superior sound quality and flexibility and because the only locomotive modification required is a speaker installation. The central sound generator and locomotive speed-control units were to be radio controlled. Block control is required to support through-the-rails sound.

All turnouts were to be equipped with microswitches for reliable frog electrical operation, and all outdoor and inaccessible indoor turnouts were to be equipped with pneumatic switch machines.

Construction

The basic outdoor shelf material is 5⁄8″, treated plywood in 4′ x 8′ sheets, supported every 16″ with a treated 2″ x 4″ joist, supported in turn by 2″ x 8″ fir girders and 4″ x 4″ treated posts. The posts are set in concrete piers and are cross and angle braced with 2″ x 6″ fir planks. A 2′-high wall is located at the back of the shelf to support dirt scenery, and the shelf and back wall are covered with a layer of 20-mil vinyl pond liner. The plywood shelf is tipped slightly to the inside to allow drainage. A 2″ underlayer of sand was placed on top of the pond liner.

A 2″ x 6″ fascia board was attached to the front of the shelf for cosmetic reasons and to prevent the sand from falling off. The fascia was set out from the shelf about l⁄2″ to allow for drainage and the crack was filled with small rocks. One 8′ section of the shelf was lowered 8″ to allow for a bridge and river scene. A bench was erected along the shelf to allow children to view the trains and to make maintenance easier. The vertical space between the shelf and the bench was paneled with rough cedar boards, in a fashion similar to the curtains typically found on indoor layouts. The indoor benchwork is all “L beam” construction, with 5⁄8″ plywood covered with 1⁄2″ Homosote.

The locomotives and rolling stock are not designed to be operated in wet weather. In order to allow train operation on the drizzly days typical of the northwest, as well as to allow construction to be carried out, a temporary greenhouse-roof structure was fabricated using PVC pipes. This structure is open at the sides and enough moisture drifts or is blown in that there is no necessity to water the greenery in the winter. A water system, with water pumped from the lake, was installed to allow summer watering, as there is no municipal water available. More than enough sun gets through the greenhouse material to keep the plants happy and, in fact, an opaque cover had to be added over a section landscaped with moss in order to prevent the moss from turning brown.

Trackwork

The first-phase trackwork consisted of both the freight and passenger yards; the turntable; a ramp to the lower level, indoor test track; and one complete indoor/outdoor loop on the upper level, approximately 110′ long.

For the outdoor portion, the curved and straight sections of roadbed base were cut from 5⁄8″, treated plywood, stiffened with treated 2 x 4s and supported by small piers laid on top of the sand. The roadbed base was covered by pond liner, then 1⁄2″, gray, Vinylbed composition roadbed was laid on top and fastened with galvanized nails. Finally, code-148 flex track by Old Pullman and Atlas was laid on top of the roadbed, fastened with small brass nails. Indoor trackwork was Old Pullman code-125 flex track and turnouts, with Caboose Industries manual turnout controls.

The first phase of the railroad was operated with great success over the summer and fall of 2000, except for unreliable operation of a few of the older locomotives through some of the turnouts.

The second construction phase consisted of adding all the indoor trackwork on the lower level, including the hidden, five-track storage yard, and finishing the indoor and outdoor portions of the two remaining loops, where the outdoor portion of each loop includes a grade from the upper to the lower level, and vice versa. The second-phase trackage was completed, including Old Pullman outdoor turnouts and a 50″ girder bridge. The landscaping around the added trackage includes a scale 100′-high cliff covered with moss and an 11′ tunnel.

The seven outdoor turnouts were equipped with waterproof microswitches for reliable frog power, and powered by Del-Aire pneumatic switch motors, as were all the inaccessible indoor turnouts. The use of microswitches greatly improved the reliability of locomotive operation through the turnouts and I intended to retrofit all the manual turnouts with microswitches for frog power.

Electrics

Each 3′ section of flex track, outdoor and indoor, has a short length of 16-gauge feed wire soldered to each rail. The other end of this is soldered to a 12-gauge distribution wire, which is soldered to a 8-gauge main buss. The block distribution wires at distances further than 12′ from the control panel are all powered through the 8-gauge main buss wires. This scheme has produced very smooth outdoor locomotive operation.

All track-power and sound-generation equipment is located at a central site next to the freight-yard throat. Presently, there is one, 5 amp PBL FSS-II unit for sound and track-voltage control, equipped with a radio frequency (RF) remote-control handset that works well at all outdoor locations. There is also one conventional, 2 amp MRC power pack used in the yard and two custom Variac control units (5 amp and 10 amp). The plan is to eventually have two additional RF-controlled sound and track power units.

Landscaping

Basic landscaping consisted of adding topsoil to the shelves, then shaping the soil and placing large, mossy rocks (much like building a conventional garden railroad), with emphasis on creating realistic embankments for the elevated sections of roadbed. Roughly 400 conifer seedlings were planted along the “ridges.” The seedlings were obtained from a local reforestation company and consisted mostly of slow-growing Sitka spruce (Picea sitchensis), with lesser quantities of subalpine fir (Abies lasiocarpa) and western hemlock (Tsuga heterophylla).

An unusual landscaping technique was the extensive use of moss. Large carpets of living moss were removed from the roof of our garage and placed on a number of vertical surfaces, as well as along the tops of some ridges. Natural-growing moss from spores also appeared over much of the ground, and will soon cover a good deal of the railroad embankment slopes and other grades with a deep, attractive green, simulating grass. Small, natural ferns also appeared. The moss obviously likes the cold winter weather and the moist climate, as it is found everywhere in our area. Corsican mint (Mentha requienii) was planted along one spot of the railroad embankment, and is doing well and spreading.

In order to minimize the effect of multiple tracks in the same scene, one fairly long tunnel was created. A wooden support structure, covered with pond liner, was built over the tunnel to allow access to the tunnel from the catwalk. Track was hidden in other portions of the railroad by dense seedling forests and by rocks and dirt embankments.

Locomotives and rolling stock

All rolling stock is consistent with the steam-diesel transition era. Southern Pacific steam locomotives dominate, since the road is a division of the SP, but with a liberal dose of the “plausible universe” philosophy as set forth by Mario Mateo in the March 2001 issue of Model Railroader. Twelve SP brass locomotives include three cab forwards; three MT4/5 Mountains; one Mikado obtained from the SF, rebuilt to SP standards, and equipped with a Vanderbilt tender; two Consolidations; two Berkshires obtained during WWII from the NKP road, repainted, and equipped with Vanderbilt tenders; and a USRA 0-6-0 switcher with a slopeback tender. There is also one tiger-stripe SP diesel switcher. Sharing trackage rights from the north are two GN brass locomotives, including an O-8 Mikado and an E-6 Class 4-6-0. Three unpainted brass diesels, including two GP7s and an SD9, are destined to be painted in branch-line Cascade Pacific colors. There are also five plastic SP diesels painted in the black-widow scheme, including two GP-9s and a three-unit EMD E-8 set.

Passenger cars consist of four complete trains, including Weaver five-car aluminum SP Daylight and NP sets; an older eight-car aluminum Oregon Central set, painted in SP Daylight colors with complete interiors, figures, and lighting; and a three-car SP heavyweight set for local service.

Brass cabooses include five SP and two GN. There are over 80 wooden and plastic freight cars from many periods, including a complete 18-car Intermountain PFE reefer train as well as a miscellaneous collection of work-train cars.

Future plans

I have received a great deal of planning and “how to” support from my friends in the Victoria 0-scale Modular Railroad Club. These friends, as well as casual visitors, seem to like to see as many different trains as possible. It is presently difficult for one operator to control three trains at once, as well as to change trains from time to time. Operation of the hidden storage yard is also tricky. Better visual presentation and control of turnout position, block activation, and train location via a well-designed control panel is one goal. Installing speakers in more locomotives is another, as is automating realistic locomotive starting sequences using the PBL FSS-II computer-control capability. Finally, converting two more track-power units to RF control is essential.

For landscaping, adding outdoor-track ballast is the highest-priority goal, as well as adding a lumber yard and an oil distributorship to the spur at the outdoor town. Carefully adding more seedlings is another goal. It would appear that one cannot have too many trees.

Greatly extending the outdoor mainline by building more shelf structures is a longer-term goal. The first phase of the extension will incorporate a “Y” to allow entire passenger trains or cab-forward locomotives to be turned around. For the outdoor extension, the plan is to have only one track, with fairly long passing tracks, all near the inside edge of the 4′ shelf, with two or more small towns. The balance of the shelf room is intended to be used for very-large-scale natural scenery, with large rocks, extensive seedling forests, and other mountain features. This portion will not use a greenhouse cover, but will be completely exposed to the elements. Adding structures, scenery, and track ballast to the indoor part is also a long-term goal.

Name: Southern Pacific, Oregon Division; Cascade Pacific Branch Line

Size: 30′ x 44′

Scale: 0 scale (1:48), two rail

Theme: Oregon, east side of Cascade Mountains

Era: Steam-diesel transition era

Age of railroad: Three years (outdoor portion)

Motive power: Track-powered electric

Length of mainline: 330′

Maximum gradient: 2%

Minimum radius: 7′

Type of track: Old Pullman and Atlas flex track

Control systems: PBL FSS-II 5 amp through-the-rails sound and control system with RF control; two custom variac control units (5 amp and 10 amp); MRC 2-amp power pack

Engines: 14 brass steam locomotives, 4 brass diesels, 5 plastic diesels

Rolling stock: 7 brass cabooses, over 80 wooden and plastic freight cars, 4 complete passenger trains

Plants on the Southern Pacific Oregon Division and Cascade Pacific Lines

Shawnigan Lake, British Columbia, Canada

USDA Hardiness Zone: 8

Heavily forested lakeside (Douglas fir, Western red cedar, alder, Big leaf maple, lakeside native willows. Rainfall, about 50 inches per year.)

Conifer seedlings

Sitka spruce

Picea sitchensis

Western hemlock

Tsuga heterophylla

Groundcovers

Corsican mint

Mentha requienii

Native moss, transplanted from garage roof

Native moss spores, growing on wet slopes

Native ferns, sprouting on wet slopes