We share five ways to make durable signs for your large-scale structures. Methods include using decals, vinyl stencils, styrene and magnets, and more.

Weathered enamel signs

Here’s an easy way to simulate old, rusting enamel signs. First, invent and print the sign, or take a photo of a real one. Print the image on glossy photo paper. Scrape away the top color in places using an X-acto knife, leaving the base color. Then, in a smaller area, scrape away further until you are left with just the ragged paper.

Apply a little gray-brown acrylic paint to the white areas, then immediately wipe it off. It will soak into the ragged paper and remain. Spray with a clear-coat sealant. Your enamel sign not only has areas where the enamel has chipped away realistically, but this has a genuine three-dimensional effect to it.

Making signs with resin

A good method for making signs is to print them on paper, then use a polyurethane resin (the stuff they use for car and boat repairs) to attach it to a wood or plastic base. Depending on the paper, you may have to paint the wood prior to gluing the two together, as the resin will soak into the paper, turning it translucent in some cases.

Removable projecting signs

Don McClure uses styrene, printed vinyl sheet, and strong magnets to make projecting signs on his garden railroad. They are easy to remove and/or replace as needed. Read how he makes them in our article.

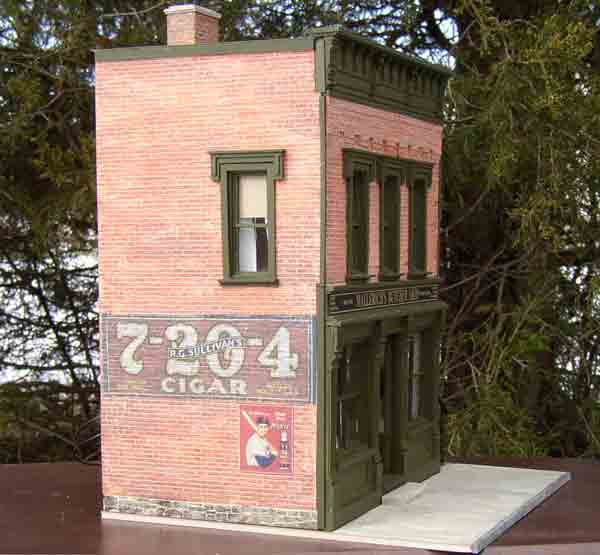

Decal signs

Bob Santos makes signs/advertisements by applying decals to his structures. The article appeared in our August 2014 issue. Bob also provided a PDF of sample signs you can download.

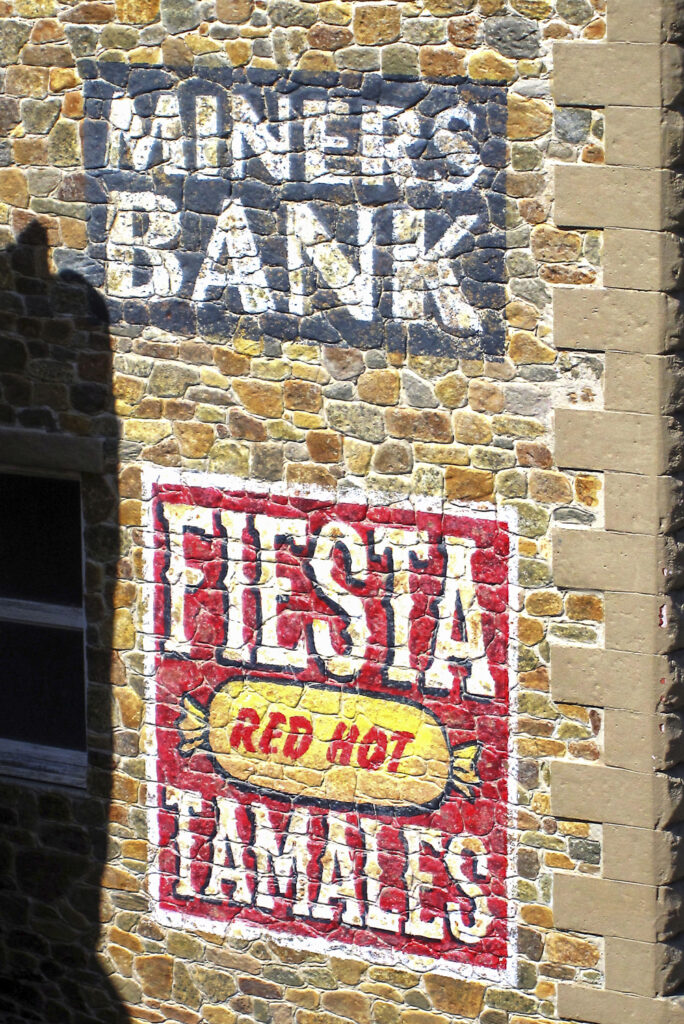

Hand painted signs using vinyl stencils

Ray Dunakin used vinyl stencils to paint signs on the sides of his buildings. For certain signs, he hand painted the letters for the desired effect. This article appeared in the February 2018 issue.