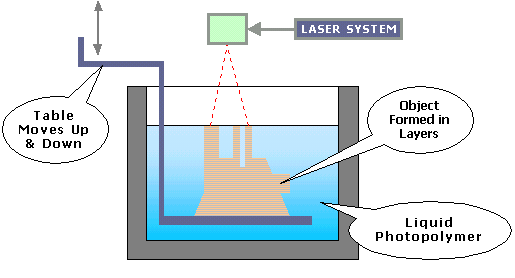

Stereolithography or SLA is known for its fine details and exactness. It uses a liquid photopolymer that when hit by an ultra violet laser it will harden. This is done layer by layer just like the FDM process except with layers about 0.025mm or 25microns. Much finer layers along with the exactness of the laser gives a part with very high resolution.

The figure shows just one of the methods to process an SLA print.

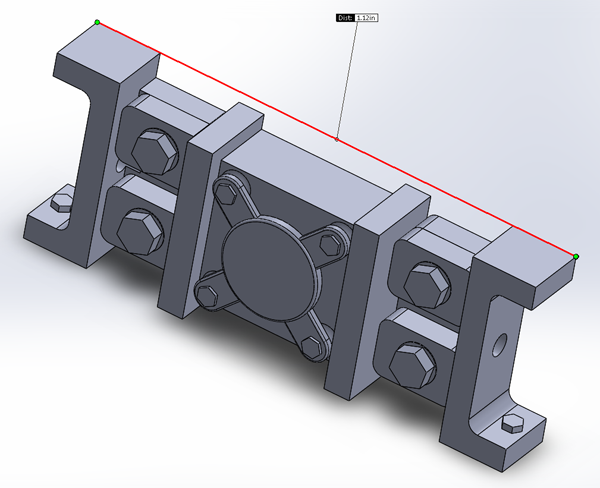

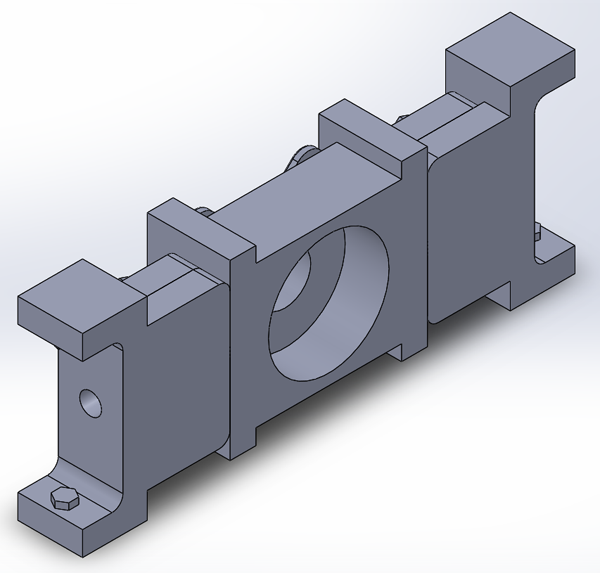

I will again use my favorite CAD program Solidworks to make this part. Converting the drawing to the CAD part is easy and should not take me too very long. In addition to the pillow blocks that have already been modeled, I will be making the journal boxes.

I do not own an SLA printer so I will have to go to a printer that has this type of machine and have it printed there. You should find many printers in your area but you will likely not find one in your local library unless you are really lucky. This machines need to be cleaned constantly and the materials are not inexpensive.

I need four of the journals, four of the suspension supports, and two of the control rod supports. The cost for these to be printed is about $100. However, the printer suggested that I fill a “plate” and the price would be $100. The “plate” is the printing surface that holds all the parts. The time on the machine is what is expensive, just like the FDM process. The actual material is rather inexpensive. The resin to be used is called Durable. It has a low coefficient of friction and is slightly flexible which is exactly what is needed for these parts.

Unfortunately to get as low a price as possible, I am at the end of the printer queue and subject to delays for larger, better paying projects. So the parts are not here yet but I will certainly talk about them in the next installment.

Summary

SLA printers were introduced and some of the benefits and drawbacks with this type of printer has been presented. This type of printer is expensive, a challenge to maintain, and should not be your first printer. However, with experience and absorbing the cost of the current SLA technology, very high resolution prints can be made. This technology also has the benefit of many different types of resins are available for different applications, like very flexible parts, or printing parts for something like a lost wax process.