Regional gardening reports

Zones are USDA Hardiness Zones

What’s your operator position on the SJR&P Railroad?

These reports were shortened in the magazine to fit the pages, but readers may read each report here in its entirety.

1. Holding Company, Stan and Deb Ames

Chelmsford, Massachusetts, Zone 6

In April 1988, we began construction of the SJR&P Railway. As soon as a simple up-and-over figure 8 was built, we got hooked on large scale. Our first expansion added a second loop, two passing sidings, and a simple yard, which allowed operations to commence. Since then each expansion has been constructed to enhance operations. Our goal was to blend the railroad into the garden while providing an operating experience that follows key aspects of narrow-gauge-prototype operations that are both challenging and enjoyable. Ensuring that the operators have fun is an important goal for us.

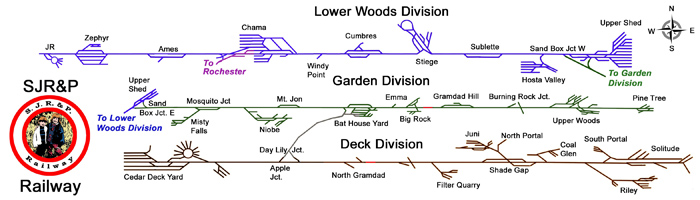

The SJR&P is currently a 1:20.3 narrow gauge railway with a standard gauge interchange. The overall layout plan is a multipoint-to-multipoint railroad with 7 destination yards, one mid-point interchange yard, numerous towns, and switching locations scattered around the railway. With smaller scales indoors, one frequent problem with operation is the short distance between towns. Being outdoors with adequate space, we have designed the railroad to have several very long runs that can take 45 minutes or longer to complete within our 4500’ of track.

Our concept is that long-distance way freights run between the various major yards. These long-distance trains are pulled by our larger locomotives, frequently double headed or with a mid-train helper. Along the route we switch cars in and out of several sidings. Once the long distance train reaches the destination yard, smaller local freights using smaller locomotives are used to perform local switching for the numerous industries and towns.

Any unscheduled train or “extra” must work around trains which are in the timetable. Most freight and work trains are never in the timetable (or schedule) so by definition they are extras.

In our case, we like to have lots of people join us for operations, but Deb and I did most of the construction. We try to have about four optional 3-hour work sessions a year because people enjoy them. While the basic track plan is nearly complete, the SJR&P continues to grow as we still have a few areas to build and there are always older sections that need to be reworked.

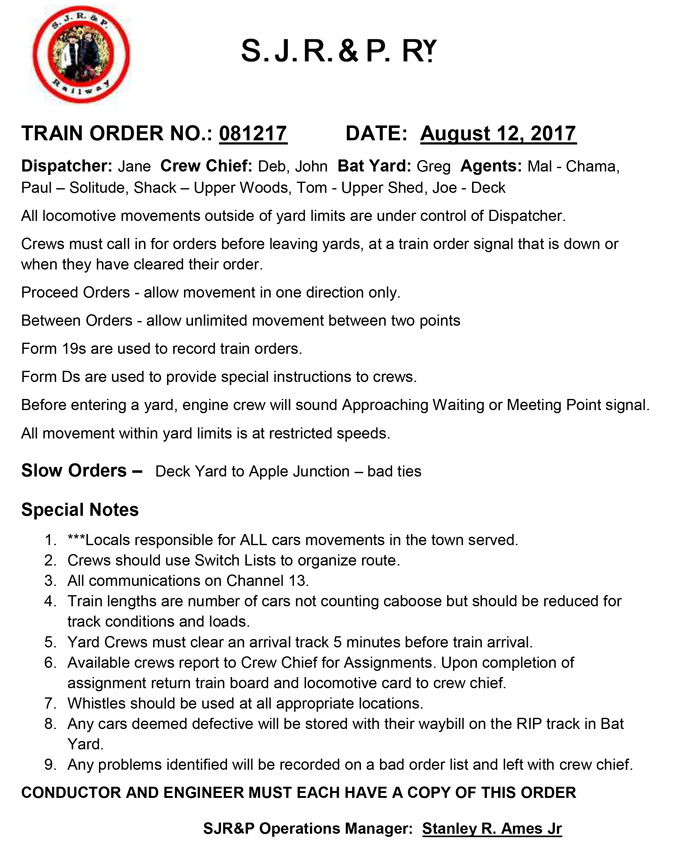

2. Superintendent Stan Ames

My job is to oversee railroad operations so that all goes as smoothly as possible. Most positions on the railroad are tied to either a location or a specific train. The Superintendent is the one position that spans the entire railroad. A day or two before the session, I “stage” the railroad by ensuring each car’s waybill is appropriate for any move the car will make during the session. This is the time I also ensure that there are suitable traffic needs to justify each train that will be run during the session. At the start of the session I call everyone in for a short meeting. I hand out the daily train order to review the day’s session, identify slow-order areas, and introduce the day’s Dispatcher and Agents. If everything goes perfectly smoothly I can relax and enjoy watching the session unfold. Alas, it seldom does.

A crew in Riley calls in with a stuck turnout that needs some adjustments, so off I go, screwdriver in hand, to fix the problem. Next, two crews call in from Mosquito Junction with a passing problem. It seems one crew forgot to tell the Dispatcher that they had a long train and both trains are too long for the siding. No problem, I explain the “double saw bye move”, (read this link: http://www.sdmrra.org/Odds-n-Ends/saw_bye.htm). Then I provide them the simpler solution for one of the trains to pull down the Misty Falls branch far enough for the other to clear and then back out and proceed. After coordinating with the Dispatcher, the simpler solution is chosen and both trains are off.

And so it goes. While at times it may appear like chaos, for the most part today’s session runs smoothly and I get to sip lemonade and eat cookies in the crew lounge (our deck).

3. Crew Chief Deb Ames

The SJR&P is large enough to need organization, especially during sessions with over 30 operators. Usually I am the Crew Chief, in part because I know the routes and the skill level (novice or experienced) of our operators. After looking at the day’s schedule I determine who can help with pre-session moves, such as relocating a locomotive to a specific yard. For teams, I look to match our regulars with new visitors.

After the Superintendent‘s meeting on the deck, I start assigning crews to trains, distribute train order clipboards, engine assignments, along with throttles, radios, paper work, pencils and screwdrivers (for uncoupling and clearing out turnouts). Before the crews depart, I answer any location and throttle questions and notify the dispatcher and pertinent agent(s) that a train has been released.

Next up on the schedule is Big Rock Local, one of our more challenging runs. The next available crew is new to the railroad with not a lot of operations experience. I quickly adjust the schedule to give them Misty Flyer (a passenger run) so that “you can see more of the whole railroad”.

If a crew takes on too much of a challenge, they will likely not enjoy the experience – kind of like skiing – a novice would have a terrible time on a black-diamond run. Likewise an expert operator would be bored operating a simple through-passenger train. To accommodate this we designed our train routes to have a variety of skill levels.

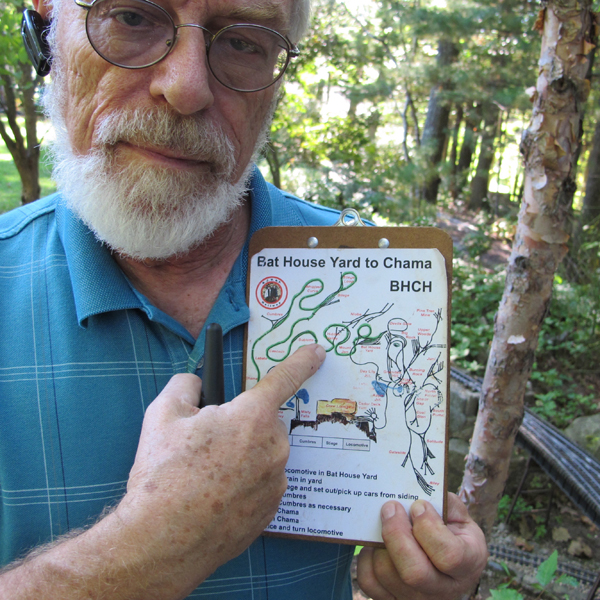

As the session progresses I get a help call from Yardmaster Greg in Bat Yard that he has a lot of cars that need to go down the hill. Since it is important that we keep the yard from being congested, I rearrange the schedule and assign the next available crew to move cars on the “Bat Yard to Chama” run.

After a crew finishes a run, they return their clipboard, tell me where they left their locomotive, and either request another run, or put their feet up and have a snack.

Now in reality, do I make mistakes? I forget to contact the dispatcher, get busy with food, or socializing. Does this matter? Not in the least! Our goal is to have a friendly, welcoming railway that everyone can enjoy.

4. Yardmaster Greg Whittle

Albany, New York

Bat House Yard is a critical location for operations on the SJR&P Railway outdoor layout. It sits at the junction of the Garden and Deck Divisions and it is the point where almost all mainline freights exchange cars.

As Bat House Yardmaster, my duties include freight agent, operating the yard engine, throwing turnouts, uncoupling cars, handling incoming and outgoing waybills, and track maintenance. I’m at the yard early to remove debris and displaced ballast to insure over 20 turnouts in the yard throw properly. Then it’s time to check the waybills and sort inbound from outbound cars left in the yard in the previous session.

Track 2 has a Riley bound car between 2 Chama cars and track 4 has Niobe and Big Rock cars intermixed. Those will need to be sorted right away. The session must be starting since I can hear crews at other locations calling the dispatcher for instructions. The yard engine will now be in continuous motion as I move back and forth throwing turnouts and uncoupling cars to sort and prepare groups of cars for each town. The Dispatcher is now calling, “Bat House: The Misty Flyer is approaching Big Rock. Can you clear the Garden Division route?” I visually check the turnouts before replying, “Bat House to Dispatch, the Garden main is clear, all switches lined and locked, send the Flyer through.”

Before the Flyer comes in sight I hear the exhaust beats of a train coming up from Day Lily Junction. The engineer says he is the Deck Local with cars for the other 2 divisions and returning with Deck Division cars. I open the wye turnout and route him up the runner where he cuts off his cars and proceeds to the passing siding. He will wait there until the Flyer goes by to allow his engine around the wye. The moment his engine is clear, my switch engine grabs his train and couples the caboose to the block of Deck Division cars on track 3.

Now there is a small amount of time to begin classifying the cars that arrived from Deck Yard. Of course once the Deck Local’s engine makes his way around the wye, I’ll shove his strings of cars out to him, clearing track 2 to separate other blocks. At the same time the Dispatcher is instructing an eastbound train on the Garden Division to take the siding at Mt. Jon to wait for the Flyer before proceeding to Bat House.

Bat yard can have multiple trains enter and exit at the same time. It is the Yardmaster’s job to manage congestion in the yard to maximize movement on the railway. This work will continue with trains arriving and departing all day. Some road crews seem to want to bring their trains into the yard and take a break while the yard switcher exchanges the cars, but that can tie up the whole railroad.

Garden Division trains are worked off the main or passing siding while trains to and from Deck Division are handled on the runner or the wye track. The road engine can assist in breaking and reassembling the train or pull out of the way while the yard switcher does the work. As the last trains of the day are tying up at their destinations, the work at Bat House is not complete. The yard switcher will still be sorting the cars into the proper blocks and placing them on the correct tracks so the yard will be ready for next session’s Bat House yardmaster.

5. Agent Dave Insley

Dunstable, Massachusetts

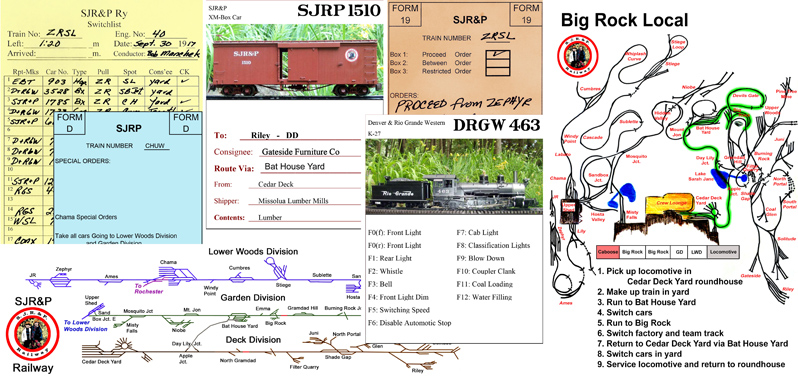

As an Agent-operator on the SJR&P, my job is to make sure all of the on-line customers in my division are properly serviced. This means I am responsible for making sure the freight moves across the railroad in an efficient and orderly manner. This railroad typically operates with 3 Agents, one covering each of the 3 divisions (see the linear schematic) on the SJR&P.

I am reporting for duty in Chama today, so first I walk the entire length of the division and check the waybills in each town, jotting down which cars are scheduled to be picked up and where they are to be delivered. I will then check the schedule of trains to run today and make notes of which cars should be serviced by each train to ensure that all the traffic needs of the division are satisfied during the session.

When the train crews report for duty, I will work with them to generate a switchlist for all cars on their train, making sure they have capacity on the train to pick up the appropriate cars along the route. We will then make sure the train is properly blocked so they can do their work efficiently. I will repeat this process with each of the train crews running in this session.

6. Dispatcher Tom Williams

Boxford, Massachusetts

Railroads are paid to move cargo and/or people from a specific pick-up location to a specific drop-off location. The higher the number of cars moved over the line per hour, the higher the payoff.

As the train crews call in for orders, I need to prioritize the trains as either “through trains” with a few quick stops or “locals” that may block the main line while they switch cars at the industries. I give passenger trains priority over all freight trains. I also have to consider the grade of the track – trains moving up hill can lose traction and stall, so they have priority over trains of the same type that are going downhill.

I will have local trains pick up cars from industries and take them to a yard where they are grouped into blocks going to distant places. When they are ready, I will route the through trains that pull the blocks to some other place where cars may be put onto local switching trains to be delivered.

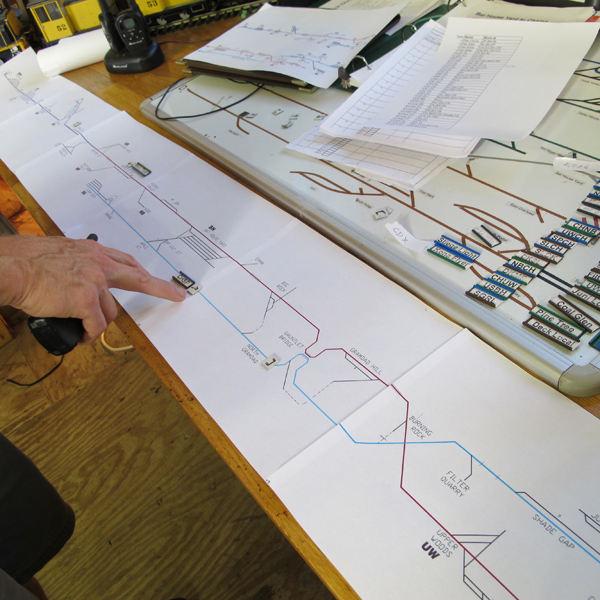

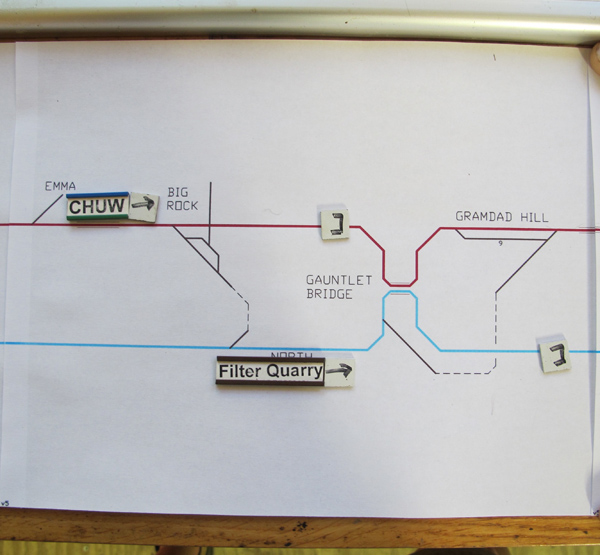

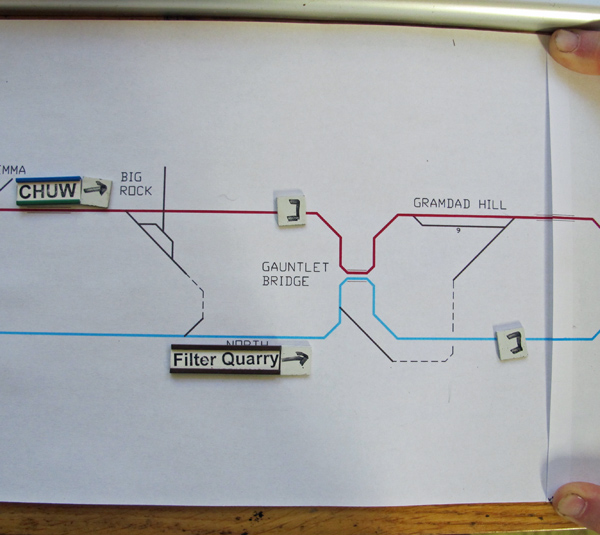

My challenge as the dispatcher is to maximize the number of trains passing over the road while following the priority rules. Since this garden railroad has a single-track mainline with occasional passing sidings, planning ahead with a map (see the schematic) helps me plan the train movements. I need to think about siding lengths, choke points and collision points along the entire railroad, and predict where collisions, meets and passes will happen. Then I call each train crew and issue the orders for trains to meet and pass at specific places. I keep track of the orders I’ve issued by moving the markers on the map. This allows me to see which segments of the railroad are occupied and where each train will be in a few minutes.

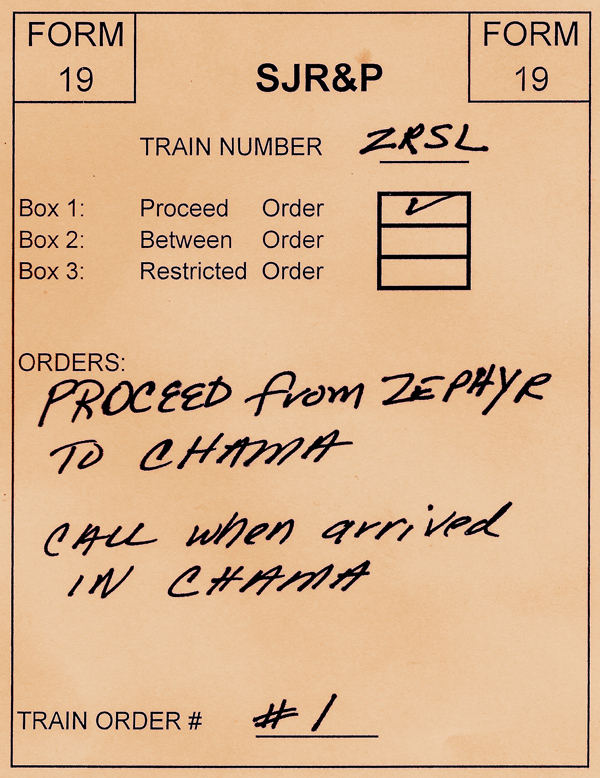

I can issue two types of train orders on the SJR&P: ‘Proceed Orders’ that allow movement in one direction only, and ‘Between Orders’ that allow for unlimited movement between two points. During a typical 3-hour operating session, 50 to 75 train orders are recorded on the dispatcher’s log sheets.

As the session begins I have the biggest onslaught of activity. The Crew Chief has released 12 trains at nearly the same time. Fortunately these are in different parts of the railroad and each crew will take a different amount of time to make up their train and clear the yard limits. In preparation I get all the trains on the board and start planning my moves.

First to call in for clearance is “Zephyr to Solitude”, a long distance way freight with lots of switching along the way, which I will have to get out of the way to let others pass during its trip. I issue it order #1 to proceed from Zephyr to Chama.

Later in the session I have two trains approaching the Gauntlet. The dispatcher’s board is used to display the trains currently on the railroad. Here we have two trains approaching the Gauntlet. Filter Quarry Local has been given permission to proceed over the Gauntlet while Chama to Upper Woods (CHUW) has been told to stop short of the Gauntlet.

Bob and Charlie are moving the through train from Chama to Upper Woods (marked as train CHUW on the map). I have already given them a “proceed order” to stop just short (but not onto) the Gauntlet Bridge, as marked by the “]” symbol on the map. They are now passing the town of Big Rock on the Red line, and they will stop a few feet short of Gauntlet Bridge so other traffic can use the bridge.

At the same time, the Filter Quarry Local is on the Blue line and I expect it to cross Gauntlet Bridge well ahead of CHUW’s arrival, so I have issued a proceed order that will get them over the bridge and beyond the collision point. If the local should be slower than expected for any reason, the “stop short order” that I issued to CHUW will protect against a collision. Once the local has crossed over Gauntlet Bridge and is safely out of the way, they will call me to update their location and I can issue new orders for both trains.

Given the size of the garden railroad, I cannot see the train crew I’m talking to, so all communications are done by radio. Each train crew should call in to get orders before they enter the main line. They should call in for additional orders when they reach their clearance point and are off the mainline (as when the run is completed or is in a yard). Crews also need to call in if they encounter a problem that will increase the time needed to reach the clearance point. The information that I need from every call includes the train number or name, their present location, and what they want from me. At the end of the call, they should repeat back the kernel of the order given to show that they understood. For example: if I say, “CHUW may proceed to Gauntlet Bridge. The FQ local is running ahead of you, so hold short at the bridge.” They could reply with ”CHUW will hold short of Gauntlet Bridge.”

7. Engineer John L. Middleton

Kennebunkport, Maine

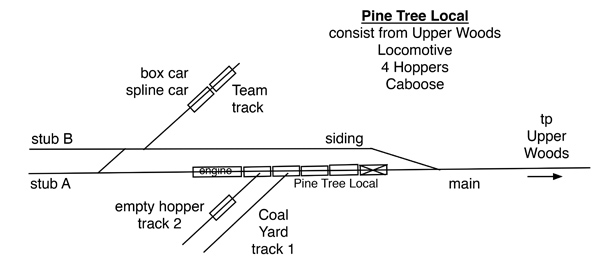

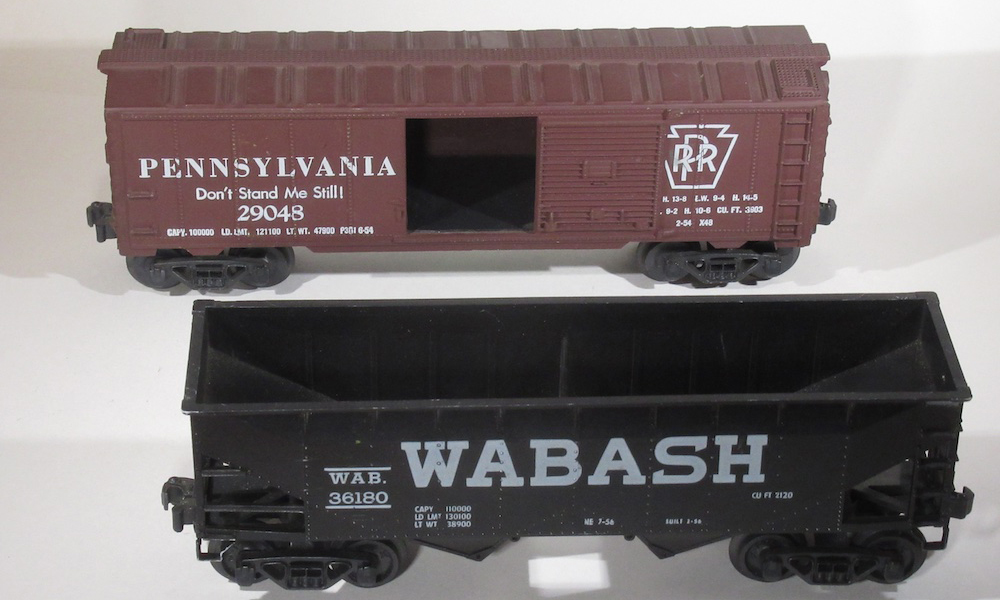

The Pine Tree Local arrives on the main at Pine Tree from Upper Woods. The waybills with the train tell the Conductor to drop the loaded hoppers at the “Coal Yard”. And the waybills at Pine Tree tell him to take the empty hopper from the coal yard along with the spline car and boxcar from the Team Track to Upper Woods Yard for further destinations. The Conductor tells the Engineer that the following moves are to be made on his (Conductor’s) command. The Conductor will set the switches as needed and uncouple when cars are spotted. Follow along on photos 7.2-7.13.

8. Conductor/Brakeman Bob Manchek

Waltham, Massachusetts

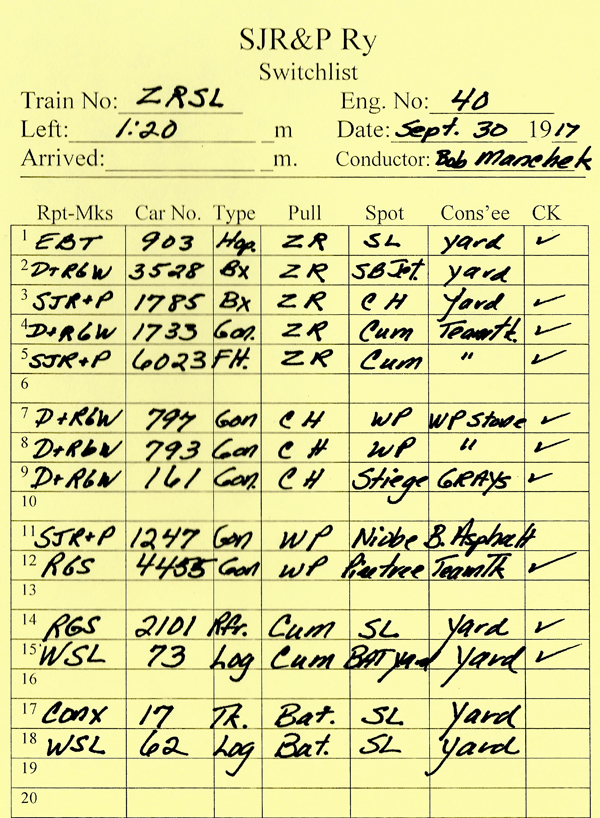

Mark and I will be operating as a two-man crew, with him as Engineer and myself as Conductor and Brakeman. It’s one of those bright fall days, starting out cold and clear but warming up quickly. Our first stop is the Crew Chief to get a route and locomotive assignment. The job today is a long-distance way freight going from Zephyr at one end of the railroad all the way to Solitude, across all three divisions. We will see a good bit of the whole layout and also have some opportunities for switching moves as we go. The Engineer takes a throttle and the Brakeman grabs a trusty screwdriver, useful for many different tasks: uncoupling cars, cleaning out switch points, and preventing the cut-off part of the train from rolling down the hill while we perform switching.

We head to Zephyr to find our locomotive, C-19 #40. With luck we find an Agent present to hand us a set of waybills. Today the railroad’s running with fewer operators so it’s up to us. We put together a train, considering the cars available, the assigned route, direction of single-ended spurs and so on. We also make an attempt to “block” [grouping cars by destination] the train for easier switching along the route. Lastly we pick up our caboose and we’re off. Before we leave the yard limits we call into the Dispatcher and receive a proceed order to Chama, which shows our first area where we need to put out and pick up cars.

The first stop is in Chama, where we have the opportunity to pick up a few more cars, but not too many, as we’re about to head uphill. It’s dry today but there’s still a limit of 6 or 7 cars that we can pull up the 2% hill without a helper. Heading up the hill at Stiege we meet with a bit of congestion. The dispatcher holds us on a siding while two freights and then a passenger train (coming downhill) are allowed to pass. Scheduling is possibly a bit off due to the weather conditions (pine needles and acorns fouling the tracks).

We finally arrive at Bat Yard and contact the yardmaster for permission to enter. We thought we only had a gondola and a log car to leave, but in fact missed setting out a few carloads at Sand Box Junction on our way up the hill, which we are now taking in the wrong direction. Fortunately, the yardmaster knows what he’s doing and sets them aside for the next train going downhill, and he’s able to find a few others for us going in our direction.

Departing Bat, we proceed into the last division and roll along with no more switching tasks until we finally arrive at Solitude. Through the wye to turn the train, we back into the yard and notify the Dispatcher that we are off the road. We leave the cars in the yard, drop the caboose on the caboose track and take the locomotive to the engine facility. Finished, we head back to notify the Crew Chief that the route is complete.

9. Operating across a gantlet, David “Shack” Haralambou

Marlborough, Massachusetts

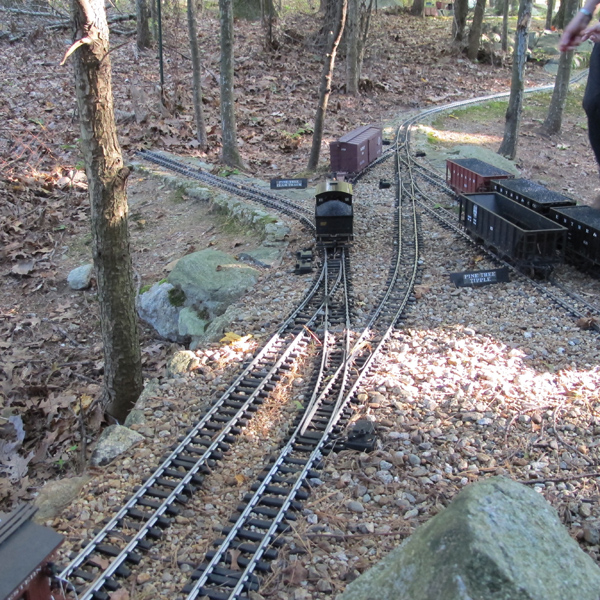

Gauntlet tracks can add an interesting operation scenario to your layout. Gantlet tracks are where two separate pairs of rails overlap each other for a section of track. Another use may be where an existing bridge cannot be widened to allow a second mainline to pass. As above, a gauntlet over the bridge would allow the traffic to maintain separate routes without mechanical switching being installed.

This is the scenario being depicted on the SJR&P Railway. In this case, two mainline tracks converge at a narrow bridge. By overlapping the tracks, as seen in the photo, a gantlet is created over the narrower bridge section. At each end, each pair of rails intersects with what looks like a standard “switch frog” – that’s how the gauntlet is built. So the inner rail of one line crosses over the outer rail of the other line. At the other end of the gantlet, the process repeats in reverse.

There are many reasons why a railroad would use a gantlet track, for instance, a narrow right of way. Maybe the railroad could not get a wide enough right of way through a particular area for two mainline tracks. Instead of putting in two mechanical switches (and all the required hardware and signaling infrastructure), the railroad could install a simple gantlet track that would maintain line separation (and not allow a train to deviate from the set of tracks it is on) with no mechanical or moving parts. Only a signal system would be needed. Additionally, block signals on either side of the gantlet could be used to manage the flow of trains through the gauntlet section.

Gantlet tracks are also used at “car-weigh stations” in order to allow the locomotive to bypass the car scales. The locomotive is switched to the other pair of rails (usually only a few inches away on 1:1 track) that are not part of the car weighing system. Once the locomotive passes the scale, it is switched back onto the main track. This allows the locomotive to remain coupled to the cars it is trying to get weighed. In the case of a scale, it is an active switch that forces the locomotive to change to the parallel tracks.

Operations using a gauntlet are simple and straightforward, as long as Dispatch remembers the golden gantlet rule, “Thou shalt allow only one train through the gantlet at any time”. So try adding a gantlet to your layout and see how interesting your next operations session can be.

10a. A tale of two rookies

Quincy Shoneman

Nashua, New Hampshire

I began learning operations in my Pop’s (Keith Shoneman’s) basement and ran with his crew of monthly operators. He had a very large two-level HO layout that was exciting to operate on. Before the age of five I started operating at the SJR&P by tagging along with my Pop and running basic excursion and passenger trains. As I grew older, I worked my way up to freight trains with car switching, and dropping carloads in yards and spurs. However, these are the only two layouts so far that I have done operations on regularly, but I hope to do more as I become more experienced.

Operations provide lots of excitement and activity to us operators. I enjoy the many different runs and excursions that are offered at Stan and Deb’s outdoor garden railway. Bat House Yard and Chama are always fun to go through because of all the action. All the different personalities and ideas from all the crewmembers are quite an experience, but without them, the operations would be much less enjoyable. Just getting to see the wide variety of locomotives and designs Stan has collected is fun.

Before my Pop’s layout had to be taken down, we began to plan a layout design of our own to build. All the techniques and tricks that I learned from Pop will help us a lot in our steady progression towards our goal. I love trains and learning about them is fun. There are so many different types of scale trains – and real ones. They provide a huge field of learning and inspiration in the model-building field.

Running and operating the SJR&P with my dad and little brother is quite the ride. I have learned to operate on my own and hope that I can teach them how to run smoothly alone as well. Operating together is a real treat because they clear the track for me and make sure all the switches are correct. Even though we are only able to drop in once in awhile, operating is always exciting at the SJR&P.

Ernie Bay

Reading, Massachusetts

When I first visited the SJR&P I was new to railroad operations having spent most of my time running large-scale trains on loops or modules. On my first visit to the railroad, I asked for a short run. Deb (our Crew Chief) gave me the run from Deck Yard to Big Rock. I started out by making up a consist with only 4 cars that were scheduled for Big Rock.

This seemed like an easy chore. Well! About 20’ into the run, the locomotive rolled over an acorn. When I checked to see what happened, the engine was damaged (repaired by next session). When I explained to Stan what happened, he said to pick another engine. I had to start over with the new engine.

A short while later I made it to Big Rock. There I discovered that what looked like a short and simple operation turned out to be fairly difficult, in my opinion the most difficult and time-consuming job on the railroad! I guess it was because it was my first run, but it was enjoyable and I was hooked.

That was some years back. Now I come to help Stan with his expansion of the railroad whenever I can. Being outside is the best way to run a railroad – we need to deal with many of the elements the 1:1-scale trains need to deal with. What I like about operations most is the social aspect and the puzzle that must be solved with each run. The people that show up at Deb and Stan’s are from all walks of life with the common desire to work on and run the railroad, thus making the visits fun and enjoyable.

Garden railroadng continues to keep family and friends together and GR magazine one away from the idiot box, I mean TV.

As one with a point to point operating railway in Belleville, Ontario, I really enjoyed seeing this article. Very impressive! I have a point to point railway in my backyard, with an approximate 500′ main line, and about 12 feet of track overall. We can operate up to 8 mainline freight trains, plus 2 yardmasters. My problem has been to find people who would like to operate, rather than just watch and take pictures. Personally, I would be bored with watching trains going around doing no work, but I do understand there are many modelers out there who enjoy building beautiful model railroads.