Accucraft Trains

33268 Central Ave.

Union City CA 94587

Price: $1,995

Website: www.accucraft.com

1:19 (16mm) scale live-steam locomotive; gas fired; single-flue boiler; 60 psi blow-off pressure; twin safety valves; pseudo-Walschaerts valve gear; D-valve cylinders; reversing from the cab; water glass, pressure gauge; displacement lubricator with drain; filler plug; regaugeable wheels (0 and 1); blind center drivers; chopper couplers; instruction manual. Dimensions: length over end beams, 12″; width, 43/4″; height over stack, 65/8″. In 1:19 scale, this works out to 19’0″ x 7’6″ x 10’6″ respectively

Pros: Faithful representation of prototype; high level of detail, excellent paint and graphics; 1/2″-diameter pressure gauge; simple to operate; excellent running characteristics; long duration; good instructions

Cons: As supplied, no way to refill the boiler under pressure; lubricator-cap access a little difficult because of roof brace; water glass too tall

Accucraft’s model is an accurate representation of the locomotive. It is painted a deep blue, lined in orange and red, with black boiler, smokebox, frames, and roof (its livery while running on the W&L). The level of (nonfunctional) detail is quite high and includes sand boxes, filler hatches on the side tanks, head and tail lamps, pilots on both ends, brake hoses, and more.

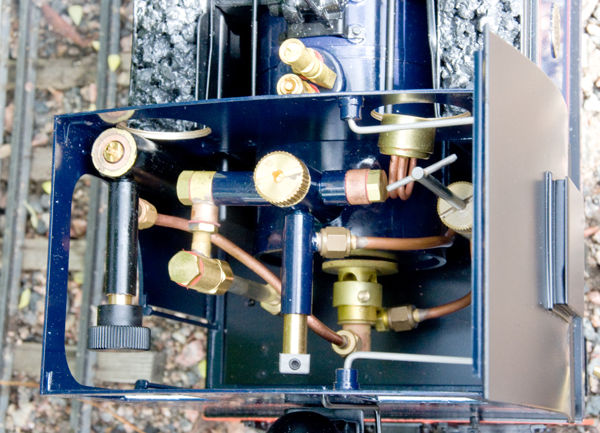

Boiler fittings include a water glass, filler plug, twin safety valves set at 60 psi, and a 1/2″-diameter pressure gauge that appears quite prototypical in size. The pressure gauge faces out the front window, making it easy to read. Purists who prefer the gauge to face into the cab will have no trouble in loosening the fitting to turn the gauge around. The boiler itself is gas fired and is of the single-flue variety. The gas tank resides in the left-hand dummy side tank, with the filler and control knob in the cab. More on this later.

Both the instructions and Accucraft’s website say that the engine is supplied with a Goodall-type filler valve to replenish the boiler water while the engine is under pressure. Our review sample, however, was not so supplied. I don’t know if this was an oversight or an error in the instruction manual. In any case, to refill the boiler on our review sample, it had to be allowed to cool.

The engine is powered by a pair of double acting, D-valve cylinders controlled by pseudo-Walschaerts valve gear, reversed by a lever in the cab. The driving axles are unsprung and the center drivers on the model are blind, allowing it to negotiate tighter-radius curves. The pilot and trailing trucks are also unsprung, though they do include dummy spring detail.

This locomotive is regaugeable, either to gauge 0 or 1. As supplied, it runs on gauge-1 track. The wheels are held in place on the axles by set screws. These seat in dimples on the axles that aid in accurately regauging the wheels without measuring tools or back-to-back gauges.

The locomotive is fitted with prototypically accurate “chopper” couplers. If these are incompatible with your rolling stock, they could be removed and replaced with couplers of your choice.

Preparations for running follow the usual routine. The cab roof lifts off to one side on its bracket. I lubricated all of the moving parts with a lightweight machine oil, then filled the boiler to about half the glass with distilled water. The height of the water glass is really too tall for the boiler and, if filled to the top nut, would cause the boiler to be overfilled. Half a glass is about right. I then drained the lubricator of water through the valve at the bottom and refilled it with steam-cylinder oil. I found that the roof bracket was so close to the lubricator’s T-handle that it was a little difficult getting the cap on and off. This is a minor problem, however. The gas tank is filled in the usual way, the filler valve being in the front, left corner of the cab.

Once all of the preparations had been made, I cracked open the gas valve and lit the fire at the smoke stack. The smokebox door on this engine does not open. The fire lit easily and flashed back into the flue. In a few minutes the needle was off the peg as the pressure began to build. At around 20 psi, one of the safeties released—the spring retainer had come unscrewed. This was an easy-enough problem to fix, and the pressure rose to 50 psi, at which time I put the engine in forward gear and opened the throttle. I expected the loco to be a little balky at first, maybe spitting hot water out of the stack. Such was not the case, though—after being pushed through just a couple of revolutions of the drivers, the engine moved smoothly away.

This locomotive is an excellent runner in both forward and reverse. Slow-speed control is also very good. One problem I did notice, which is common with tank engines, is that the gas pressure would not remain steady. This is because the gas tank sits next to the boiler and heat from the boiler increases pressure in the tank. While this is not a dangerous situation, when the gas-tank pressure increases so does the fire, then the boiler pressure, and the speed of the engine. To compensate, the gas valve had to be turned down periodically to maintain a constant boiler pressure (and hence speed). The burner is relatively quiet for a poker-type burner and the engine’s exhaust beats were clearly audible. Runs of a half hour or longer are easily attainable.

Not only is this engine a great runner, it is an accurate model of a beautifully proportioned locomotive. Operating it was a great pleasure—it’s simple to run and obedient, with more than enough power to pull a train of prototypical length.