1:20.3, gauge 1, live-steam 0-4-4 Forney

Accucraft

33268 Central Avenue

Union City CA 94587

Price: $659

Web site: www.accucraft.com

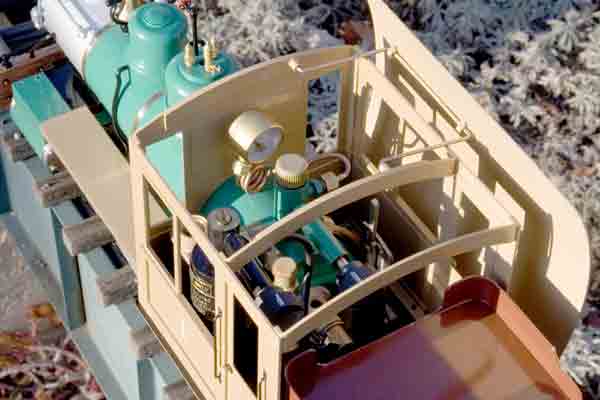

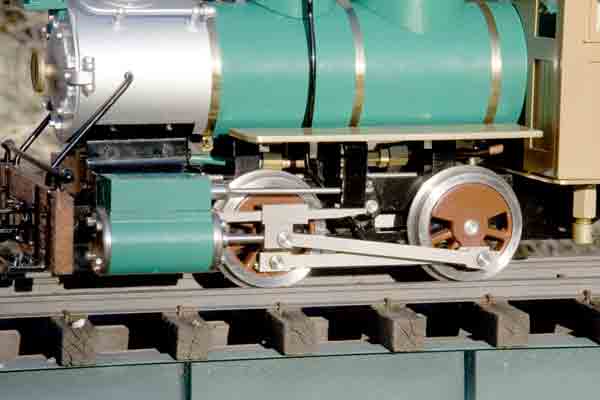

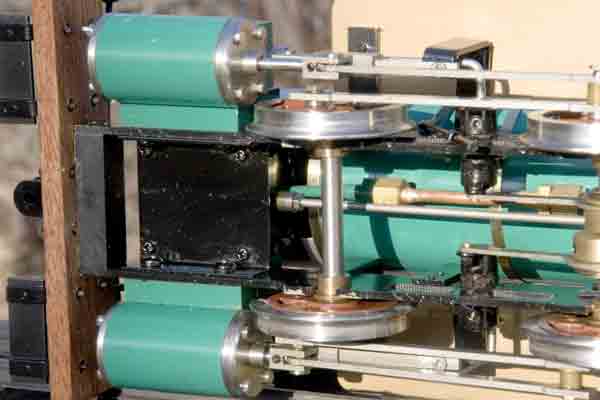

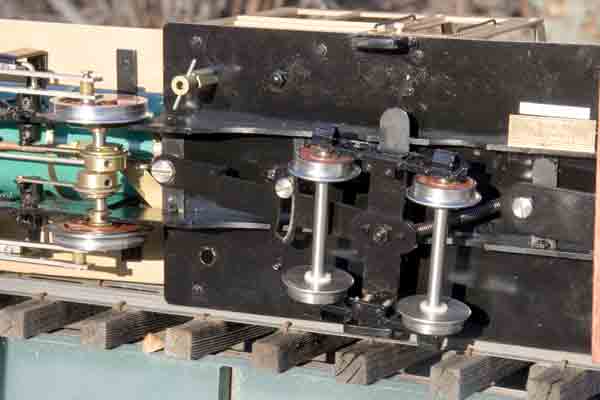

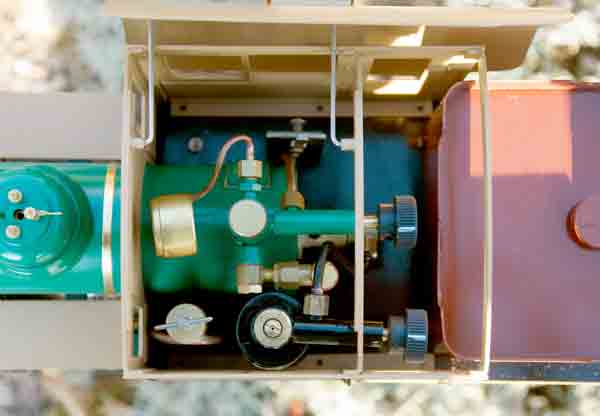

Freelance, live-steam Forney; all-metal construction; two double acting, piston-valve cylinders; piston-valve reversing; link-and-pin couplers; 50 psi blow-off pressure; single flue, gas-fired boiler; boiler fittings include safety valve, pressure gauge, throttle, water glass; instructions included. Dimensions: Length, 13¼”, width, 4¼”, height, 5¾”. In 1:20.3 scale, this works out to 22’5″ x 6’9″ x 9’9″, respectively

Pros: Solid construction; acceptable level of detail; boiler fully fitted; reversing from the

cab; can be radio controlled; easy access to cab controls through hinged roof; relatively simple operation

Cons: Safety valve cannot be easily accessed; boiler runs out before gas tank; garish colors

on review sample

Accucraft’s engine is not a model of any particular prototype, but follows the Forney’s precepts in its construction. It utilizes the same technology employed in the Ruby locomotives, with piston-valve cylinders, reversed by an additional piston valve controlled by a lever in the cab. This latter valve changes the steam admission and exhaust to the cylinders, hence reversing the engine. This locomotive has the additional benefit of a pressure gauge and a water glass. The hinged cab roof swings to one side for easy access to controls, which are all manual. The locomotive could be radio controlled fairly easily.

The boiler is a single-flue type, butane fired, with the butane being carried in a tank by the left side of the boiler. I would like to have seen it carried in the bunker, which actually isn’t used for anything. Both gas and extra water could have been carried there, but perhaps not for the same price. The safety valve lives inside the steam dome. I found the dome quite difficult to remove. It unscrews from its base, but was very hard to get started. The safety valve itself is Accucraft’s usual toy-type valve. A proper pop valve would have been nicer, though the valve supplied is perfectly safe.

The rear truck is rigidly attached to a bar that swings radially from a point just behind the rear driving axle. A spring connecting the rear of the truck to the frame helps it to return to center. This arrangement, coupled with some lateral play in both the drivers and the truck axles, should get the engine around most curves down to around 6′ radius. I think the geometry of the rear-truck assembly could have been better and might prove problematic on tighter curves. My track has a minimum radius of 13 feet, so I had no difficulty with this.

The livery on our review sample is reminiscent of one that you might see at an amusement park-lots of bright colors. Fortunately, an all-black version of the locomotive is also available.

Preparing the engine for a run is straightforward. Oil all moving parts with a lightweight machine oil, fill the displacement lubricator in the cab with proper steam oil, add water to the boiler through the filler plug atop the throttle, until the glass shows about two-thirds full, and fill the gas tank. When all that’s done, open the smokebox front, crack the gas valve (the left-hand knob in the cab), and strike a light. The fire should immediately pop back to the burner. Close the smokebox and let it cook until the gauge shows at least 20 psi. Then put it into gear with the reverser, open the throttle (the other knob), give it a push to clear the condensate, and enjoy the run.

I did all of the above to prepare the engine for the test run. The day was pretty chilly, with temperatures in the low 40s. I got the engine ready indoors, then took it outside. The fire caught immediately and, within a few minutes, pressure was up. I opened the throttle and gave the locomotive some nudges to clear the condensate. Once this was accomplished, the engine took off on its own.

The run was everything one could wish. The locomotive ran smoothly and strongly in both directions. Because of the cold weather, the steam effects were wonderful, as it lapped my track time after time. I ran the engine twice, with similar results both times. Both the throttle and the gas control are a little touchy. This is partly because the knobs supplied do not offer as much control as levers would. However, the engine is controllable and, with the added weight of a train, should throttle down nicely. I found that the boiler tended to run out before the gas, which is something you’ll need to watch. When this happens, immediately turn the fire off.

In all, this appears to be a very good engine. It is well made, well proportioned and runs very nicely. If you’re interested in a new narrow-gauge locomotive, this is definitely one to consider.