Accucraft

33268 Central Avenue

Union City CA 94587

Price: $3,150

Website: http://accucraft.com

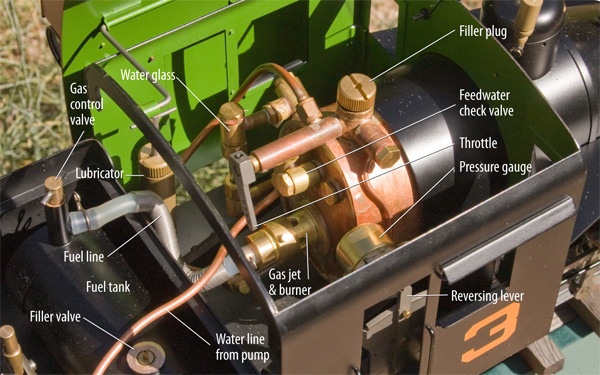

All metal live-steam model of West Side Lumber Co. Heisler Nº 3; manual control; two double-acting D-valve cylinders; working cylinder drain cocks; reversing from cab via working Stephenson’s valve gear; hinged roof; pressure gauge; water glass; safety valve; filler plug in cab; displacement lubricator with drain; hand pump in bunker; butane fired; 60psi working pressure; copper single-flue boiler; working knuckle couplers; minimum radius, 48″. Dimensions: length, 19″; width, 53/4″; height, 71/2″. In 1:20.3 scale, this translates to 32’1 3/4″ x 9’8 3/4″ x 12’8 1/4″, respectively

Pros: Well designed and constructed model; faithful rendition of prototype; excellent paint and graphics; relatively high level of detail; prototypical drive system; excellent running characteristics

Cons: Dummy oil-bunker top must be removed to fill and adjust gas and pump water; oil-bunker top doesn’t fit very well; smokebox door could use a better latch

The prototype of the model being reviewed here was built for the West Side Lumber Company in 1900. It was initially built as a three-foot-gauge engine but, in 1947, was converted to standard gauge by the (relatively) simple expedient of lengthening the axles. It was later converted back to narrow gauge and is running today on the Roaring Camp and Big Trees Railroad in California as their Nº 2.

Accucraft’s model is a close replica of the prototype. While there are some detail differences (the sand dome is tapered on the prototype but not on the model, for instance), the overall proportions and dimensions appear to be very close to the original.

The engine is painted black, with a dark-gray smokebox, boxcar-red roof, and orange lettering. The end beams and steps are also boxcar red. Paint and graphics are up to Accucraft’s usual high standard. The detail level is pretty high, with such niceties as sand lines, dummy oil cups on the rod ends, wood grain on the end beams, working coupler lift bars, dummy headlights, etc.

Mechanically, the model is set up in the same way as the prototype. A massive truss frame forms the engine’s backbone—it even goes through the cab. A V-2 steam motor is mounted to the frame, beneath the boiler, and carries two double-acting D-valve cylinders. Valves are controlled by Stephenson’s valve gear, each valve running off of two eccentrics and the typical curved, sliding die block. This is actuated by a reversing lever on the cab’s right side. The motor powers a central driveshaft connected to each truck through flexible U-joints. The shaft drives the outboard axle of each truck through a 2:1 reduction gear. The inboard axles are powered by the side rods unique to the Heisler.

For access to the controls, the roof is hinged to the side in the usual Accucraft fashion. Boiler fittings include a safety valve, concealed beneath the steam dome and set to 60 psi; a throttle lever; a check valve from the hand pump in the bunker; a pressure gauge; a water glass; and a filler plug. The bunker is covered by a dummy oil tank that lifts off. Beneath it is a large butane tank with the typical Ronson-style filler valve and a control valve.

The bunker is intended to hold water and there is a hand pump built into it for adding water to the boiler while the locomotive is in steam. I had some difficulty with the bunker top. It has notches in the front wall to clear the gas and water lines. However, they don’t line up well. Either the silicone gas line must be forced to line up with its notch or the tank top sits at a slant. And, when the top is properly positioned, it is somewhat difficult to remove. Also, with the top in place, there is no access to the gas filler valve, control valve, or the hand pump. Supplied with the locomotive are a comprehensive owner’s manual, a large syringe for water, a small syringe for steam oil, two hex-wrenches, and a pump handle.

Steam-test day was a warm fall afternoon. Preparing the locomotive for operation is straightforward. I oiled it all around (all moving parts) with a lightweight machine oil. I then filled the lubricator with steam oil and the fuel tank in the bunker with butane gas. The boiler can be filled two ways: via the hand pump in the bunker or through the filler plug atop the boiler in the cab. I chose the latter, putting in 200ml of distilled water.

I had a little trouble lighting the fire, as supplied. It would burn in the smokebox but not in the flue. I adjusted the air-intake sleeve at the cab-end of the burner, at which time the fire flashed back to the burner as it should, and all was well.

Pressure came up to 40 psi in around eight minutes. I opened the cylinder cocks, which are easily accessible, then opened the throttle. A little condensate came out of the drain tubes and the engine was immediately away. I closed the cocks and let it run.

The engine is easily controllable. The throttle is within easy reach through the open cab back (with the bunker top removed). I found reversing easiest with the roof lifted.

Performance was excellent. Running light, the engine could be throttled down to a walking pace on dead-level track. At slower speeds, individual exhaust beats are clearly audible, even over the sound of the burner. Top speed is faster than the prototype, but it’s easy to keep the engine below that. With its gearing, this is a heavy, powerful locomotive capable of pulling a substantial log train. Slow-speed operation is better with a train in tow.

The total run lasted around 35 minutes before the engine showed signs of running low on water. There was still gas in the tank, so I shut it off. I could have pumped up the boiler with the bunker hand pump and continued. The run was impressive. I noticed, however, that the safety valve was apparently stuck, as it never blew and the pressure rose to over 75 psi (blow-off was supposed to be at 60). I regulated the gas to keep the pressure between 60 and 75. The engine has a hundred-pound gauge on it. Higher pressures could damage it, though the boiler would be safe. The safety valve is hidden under the steam dome. The only way to get to it is with tools, making it inconvenient to tweak it with tweezers or pliers to make sure it is free. In this instance, a good tweak would have solved that problem.

This locomotive is supplied with manual controls. With a little work and ingenuity, it could probably be R/C’d. One servo could control the throttle and another the Johnson bar. It looks like there might be enough room in the roof for batteries and a receiver.

I left the engine to cool with a full bunker of water. When I came back, the bunker was empty! It took me a moment to realize that the line from the pump had acted as a vacuum tap. As the boiler cooled, the vacuum that formed inside sucked in the bunker water through the pump and its plumbing, thus refilling the boiler. On some locomotives, this is actually a design feature. On this one, it is just an unintended perk.

Overall, I was quite pleased with this locomotive. It’s well designed and made and is easy to run. It has great strength and duration, is easily controllable, and really looks the part, with its flailing motion, delicate spoked wheels, and distinctive side rods. If geared engines are your thing, definitely have a look at this one.