1:20.3 scale, gauge 1,

three-truck Shay

Bachmann Industries, Inc.

1400 E. Erie Avenue

Philadelphia PA 19124

Price: $1,000

Web site: www.bachmanntrains.com

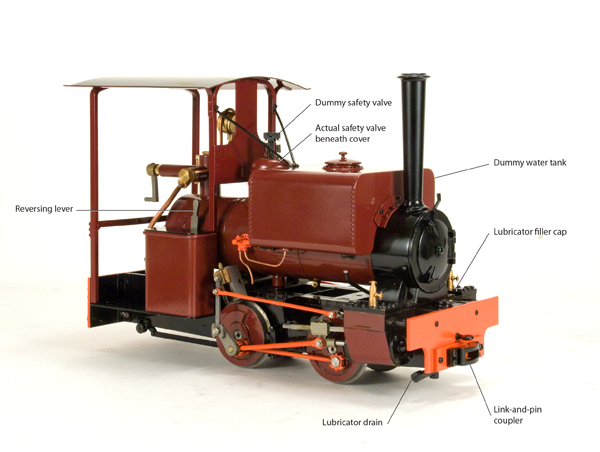

Plastic-and-metal model of a 55 ton, three-truck Shay; tested locomotive (#82498) is painted, unlettered; wiring and parts diagram; DVD showing locomotives in use and lubrication procedures; new warranty statement; engineer and fireman; optional smoke stacks and fuel loads included; variety of road names and paint schemes available. Dimensions: Length over end beams, 267/8″; cab width, 41/2″; rail head to roof vent, 7″; rail head to top of whistle, 71/4″

Pros: A nice addition to the logging line; good detail and quality; excellent running characteristics; good fidelity to prototype

Cons: Lubrication instructions inconveniently on a DVD-instructions should be in print to be used outdoors; part numbers referenced in the drawings have no meaning outside of the factory-ordering by part number will not be effective

The deck is bobbed almost to the rear truck bolster, with an all-new fuel bunker that is shorter than that on the two-truck unit. There are no “water legs” in the shell, as it just carries fuel, so the front bulkhead of the tender shell is almost flat, making the space on the deck appear smaller than it is. Our sample came with the oil bunker on the shell, held in place with foam rubber packed tightly along the back edge of the bunker. When I removed the foam rubber, the bunker was not attached with screws. A coal pile is also provided in the Styrofoam container, and the four screws necessary to secure either the oil bunker or coal load are in a small bag with the coal pile.

Also in the top of the Styrofoam container are optional smoke stacks, one like the on the early Ely-Thomas two-truck Shay, one like that on the Pardee-Curtin, and the third a cabbage stack. A straight stack is installed. The installed stack pulls out with a firm, careful motion, and the optional units press into the top of the smokebox after aligning the key with the slot. Various units not reviewed have different options for stacks and fuel loads; some have only what is installed on the locomotive, with no optional parts.

In the container is a bag of small parts and detail pieces, to be added to the locomotive as you see fit. Bachmann’s ubiquitous bow-legged fireman is included, and the engineer included is the Sherman Pittin figure from the 4-6-0s, not the cowboy-hat-wearing 1:20.3 engineer included with the 2-8-0.

The second truck is not in the same location as on the two-truck Shay. Centerline spacing of the truck bolsters from truck one to truck two is 1215/16″, while on the two-truck Shay it is 135/16″, making the first two 3/8″ closer together, which is correct.

The third truck attaches to the main locomotive body with a metal drawbar and an eight-wire plug, which fits under the third-truck chassis, wires of which are divided into two, four-wire bundles, inserted in flexible hose. These simulate the water hoses from the water bunker to the main locomotive.

As delivered, this unit ran on R-1 (sharpest) curves in both directions with no problem. The DVD shows two holes in the drawbar to alter the tender position relative to the main locomotive. As produced, however, there is only one hole available, and this is done on purpose. If the third truck was close-coupled and the engine went around a right-hand R-1 curve with a heavy load, there would be a high chance of the slip-joint between #2 and #3 truck drivelines bottoming out and snapping a plastic U-joint ear. Once you are familiar with the locomotive and what it will do on your railroad, you can change this spacing without the worry of breaking parts. To do this, turn the main locomotive over, remove the second truck, and remove the drawbar cover in the end beam. You’ll find that that end of the drawbar has two holes in it. You cannot simply move it to make the distance shorter, as the pocket isn’t deep enough, so reverse the drawbar and re-assemble. There is a removable, metal water siphon pipe from the back of the fuel bunker to just over the water bunker hatch. When you shorten the drawbar, you will find a shorter siphon pipe in the top of the Styrofoam container.

The third truck has the backup light, third power unit, speaker mount, and a functional water hatch with hinges. Rivet detail is crisp and nicely done. The rear of this section has the normal end beam, steps, sand box, and coupler of the two-truck Shay.

There is plenty of available space for installation of radio-control systems and batteries.The space in the third-truck bunker makes a good speaker enclosure for the installation of an aftermarket sound system. Those who install reed switches for track magnets will find the trucks are the same as on the last two-truck unit.

The back-to-back dimension of the wheelsets, while just under G1MRA and NMRA standards, are well within the allowances found in the garden. The minimum was 1.554″ on our sample, while the maximum was 1.563″. G1MRA/NMRA uses 1.575″ as the median.

Current and voltage readings are as follows: Forward-1.4V, .5A starting; 1.9A at 12V, full slip; reverse-1.6V, .5A starting; 1.8A at 12V, full slip.

Just as this review was being prepared for print, Bachmann’s new 1:20.3-scale freight cars arrived. After placing the new cars on the track next to this Shay, with the installed high-level couplers on the cars, I looked for matching couplers in the new Shay’s packing. There were none. I contacted the manufacturer and was told that since this engine is a re-issue of an older design, no couplers are provided for the higher height and the modeler is expected to add his or her own.

I have some experience with Shay coupler mounting and I believe that an offset coupler, attached to the existing truck-mounted coupler arm, is not ideal when dealing with rolling stock that has body-mounted couplers. The end beams of the locomotive should be extended downward after the original couplers and mounts on the trucks have been removed. Add a “third” beam under the existing beams (I use 1/2″ x 1/2″ mahogany plant stakes). This will give ample support for body-mounting couplers to the face of the new beam, while at the same time closing the gap between the bottom of the end beam and the pilot step. The existing link-and-pin coupler pocket on the end beam must be relocated higher or removed entirely.

Despite these complaints, this locomotive represents a good value for the hobbyist who has need of this type of locomotive on his railroad. It runs well and looks great.

NOTE:There is an issue that consumers should be aware of regarding the wiring, which, if attended to, may preclude a need to return the unit for service.