1:20.3 scale, gauge 1, archbar-truck kit

East Gary Car Company

3828 St. Joseph Court

Lake Station IN 46405

Price: $24.95/pr. + $5 s&h

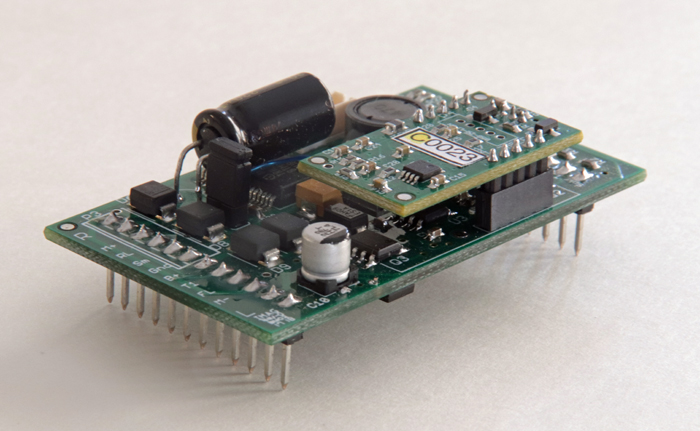

All-metal truck kit; white-metal frames and bolsters; insulated steel wheels and axles; instructions supplied. Wheelbase, 2.103″; wheel diameter, 1.275″. In 1:20.3, this works out to 42.69″ and 25.88″, respectively

Pros: Simple construction; beautiful wheel profile; spot-on back-to-back dimension at 1.575″; free rolling, with work

Cons: Unsprung frames; trucks require a fair amount of work to achieve optimum performance

There is some light flash and some sprue stubs on most of the parts, which had to be cleaned up. This I did easily with a file and an X-acto knife. Journal lids must be glued in place. To ensure a better bond, I filed the backs of the lids flat and also the mating surfaces on the ends of the journals. This gave better contact area when I CA-cemented the parts in place.

On the inside of each frame, behind the dummy, cast-in springs, is a hole. Screws are supplied that you must screw into these holes, thus threading them. Once in the holes, the screws are backed out a little, but left in place. The bolster ends are slotted, the slots sliding over the screws, which are then tightened. On our review sample, the slots were a little too narrow to slide over the screws. The instructions recommended filing them to size, which I did with a small flat file.

Assembling a truck is a simple matter of attaching the bolster to one sideframe, dropping the wheels into the cast-in axle holes, then attaching the other frame. I had some problems with the axle holes being a little too shallow, binding on the axle ends. I drilled them slightly deeper, which solved that problem. The axle holes are significantly oversize for the axles, but this does not seem to hamper their rolling characteristics. When all is well, and the axles oiled, the trucks are quite free rolling. If the axle-hole size bothers you, I would suggest drilling them out and installing brass or bronze bearings.

The trucks are unsprung. A little equalization can be attained by backing off the side-frame screws slightly. If the bolster wants to slip off, I found that by squeezing the open ends of the slotted part with a pair of pliers, the metal could be deformed just enough to prevent the trucks from coming apart without affecting operation.

The finished trucks look fine. The cast-in spring detail is not as crisp as might be desired, but this is a small matter and not noticeable at any distance. If you are scratchbuilding freight cars, either D&RG or freelance, these trucks could do well under them.