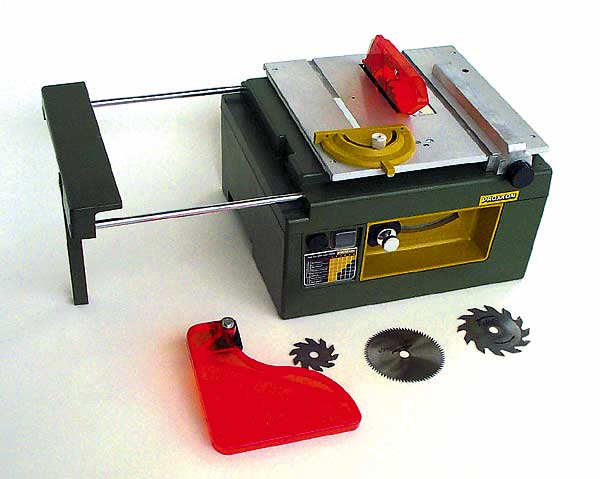

Miniature table saw

Proxxon Tools

Proxtech

2555 Tate Blvd. SE

PO Box 1909

Hickory NC 28603

Price: $319 + s&h

Web site: www.proxxon.com

Miniature table saw with heavy plastic body; machined-aluminum top; extension wing; fence for ripping; miter gauge for cross cutting; 24-tooth, 3.35″ diameter, tungsten-carbide-tipped blade; blade tiltable to 45°; variable-speed motor; instruction booklet

Pros: Well built, versatile tool; rigid work surface; rigidly mounted motor assembly; fence can be used to right or left of blade; fully functioning blade tilt and height adjustment; relatively quiet in use; powerful motor; able to cut all types of wood, as well as non-ferrous metals, plastics, and other materials

Cons: Blade guard interferes with fence when fence is set close to blade; fence not adjustable for squareness; speed-control knob a little awkward

The instruction booklet is minimal. It mostly contains dire warnings and cautions, which, I supposed, it had to include. Having said that, safety is a paramount issue with a tool like this, as it can be dangerous if not fully respected and understood. The booklet does cover how to mount the saw to a work surface, how to install the blade guard and change blades, and how to do standard maintenance. Most of this is explained with pictures. The instructions strongly suggest mounting the saw permanently to your workbench. I didn’t have this much space to permanently give up, so I mounted it to a board instead, which I could clamp securely to my work surface. This worked fine. To do this involved locating and drilling four holes in the board, through which four screws were passed from the underside and screwed into threaded holes in the bottom of the saw.

The saw comes with a sort of universal vacuum attachment, a multi-size rubber tube that plugs into the back of the unit. I had no difficulty connecting my Sears shop vac to this. A vacuum is highly recommended to prevent the cabinet from filling with sawdust.

On the front panel is an on-off switch and a speed-control knob. It’s a little difficult to get big fingers around the knob, but this is a minor issue. Also on the front of the saw is the device used to both raise and lower the blade and tilt it. Both functions have positive action and you won’t accidentally do one when you meant to do the other. A built-in table extension resides in the left side, which gives an additional 8″ of support for longer work pieces. This slides out (or in) as necessary.

The fence engages a slot under the front edge of the table. The fence itself is a single, rigid casting and is not adjustable for squareness. The one supplied with our review sample was quite square, but it’s always nice to be able to adjust it.

The miter gauge has a plastic body, which seems adequate to its task. It does have holes in its front edge, so an extender piece could be screwed on, increasing its effective width and usefulness. A blade guard is also provided, which serves to protect the fingers in most situations. However, if the fence is moved very close to the blade for making very thin cuts, the blade guard interferes with it and must be removed. If you do this, exercise extreme caution when using the saw.

When turned on, the saw is pretty quiet-far quieter than the vacuum I used with it. I raised the blade to the highest position, which is just high enough to cut through a 1 x 4 (which is actually 7/8″ thick). With the speed cranked up all the way (6,800 rpm) and the standard 24T carbide blade installed, I fed through a variety of different woods, from very soft redwood to hard oak and maple. The saw showed no signs of retreating from any of these challenges, and easily munched through all that was offered. With the blade tilted, more was fed through. The angle was held perfectly throughout. Then I tried some precision ripping, using a dial caliper to set the fence specified distances from the blade. I found that it was not difficult to hold tolerances in the .005″ range.

I then changed the blade to the 80-tooth “Super cut” blade, but did not like it as well. It had a thinner kerf (width of cut) but seemed more sensitive to the grain of the wood, producing a rougher finish.

Also available is a dado head. This is an attachment normally used for making slots in wood. This attachment was unlike those I was familiar with, being neither a wobbler nor a set of stacking blades. In fact, it is just a single, 2″-diameter blade of .08″ width. It comes with a separate, swing-aside blade guard, as the regular guard would not allow the work to pass when cutting slots. To cut a slot wider than .08″, the work must be passed through the blade multiple times, moving it slightly each time. I found the dado attachment to be of limited utility.

The saw itself, though, is a fine piece of equipment. It is powerful for its size and is capable of making clean and accurate cuts in a variety of different materials. It’s easy to use and does everything you’d expect a good table saw to do.