Proxxon Tools

PO Box 1909

Hickory NC 28603

Price: $300

Website: www.proxxon.com

9 3/4″ disc sander (#TSG 250/E); cast-aluminum housing; double ball-bearing spindle; aluminum, tilting work table; electronic speed

control; adjustable miter gauge; owner’s manual; approximate footprint: 11″ x 11″; height, 14″

Pros: Solid construction; easily replacable sanding discs; variable-speed motor; adjustable angle on both work table and miter gauge; relatively quiet

Cons: Miter gauge tends to catch on black plastic mounting bracket at the end of the work table

The owner’s manual, which is entirely in English, covers a lot of the usual stuff—safety, electrical information, technical data, care and maintenance, what’s in the box, etc. Also included is information on removing the sanding table from the powered disc unit, anchoring the sander to the workbench, adjusting the sanding table, working with the miter gauge, adhering the discs, and hooking up a vacuum to the unit using the supplied rubber port. The last page of the manual has an exploded drawing of the entire machine, which I found refreshing in this day of products that were never intended to be repaired or serviced.

The machine itself is well engineered and robust in its construction. The primary housing is an aluminum casting. To the rear of this, a plastic enclosure for the motor is attached. There’s both an on/off switch and a speed-control knob on the motor housing. A heavy cord, approximately seven feet long, exits the motor housing. This has a standard three-prong plug. On the top of the motor housing, near the speed-control knob, is a chart with suggested sanding speeds for different materials, including soft wood, hardwood, plastic, non-ferrous metal, steel, glass, and ceramics.

To attach a sanding disc to the machine, the sanding table should be detatched, a matter of removing two screws with an Allen wrench. Once the table is off, the disc is completely exposed. The backing paper is simply removed from the sandpaper disc of your choice and it’s then stuck to the sander’s disc.

The machine has an interesting feature I’ve not seen before. The disc is covered with an adhesive silicone film. The sandpaper is applied directly to this, rather than to an exposed-metal disc as on most sanders. This allows the self-adhesive sandpaper disc to be quickly and easily removed—just peel it off. Here’s where the supplied special plastic-film sheets come in. You can use them to preserve the adhesive on the back of the sandpaper disc so that the disc can be reused—a pretty cool feature.

The supplied sandpaper discs are of industrial quality (made by the German company Starcke) and are intended for long use. They can be used on a variety of different materials, including wood, metals, and plastics. An optional liquid cooling system is available from the company.

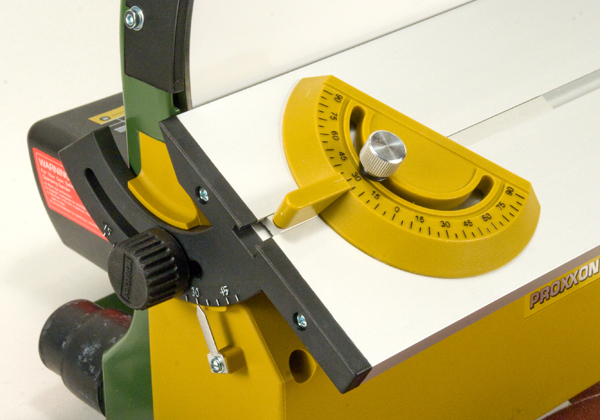

The machine is a pleasure to use. While it can be secured to the bench, for occasional use that isn’t necessary. Weighing only around 12 pounds, transporting it is easy. There’s even a recess in the back that acts as a hand grip. The table adjusts by loosening two knobs, one at either end. It can be angled as much as 45° down or 15° up, with respect to the disc. The miter gauge is adjustable up to 90° in either direction. It is held securely in a T-slot on the table. To remove it, it must be slid off either end. Here is where I found my only niggle. The miter gauge tended to hang up when it hit the black-plastic bracket at either end of the table, which slightly overlapped the slot. This was easily remedied by a little judicious filing with a small flat file.

As mentioned above, speed is controlled by a knob. Power is transferred from the motor to the disc by a concealed toothed belt. While the machine is easily powerful enough for model work, it is not intended for heavy sanding of large items requiring a lot of pressure. In fact, a label attached to the body warns against excessive pressure. I did some sample sanding on a variety of materials, including pine, maple, brass, and steel. No problems were encountered with any of these materials. The combination of the quickly tiltable table and adjustable miter gauge made compound angles a snap.

Once again, Proxxon has come up with a winner. This is a dandy little sander that I would recommend to anyone doing model work who was in the market for one.