Railbed Systems

100 McIntosh Lane

Hampstead NH 03841

Prices: See website

Website: www.railbed.net

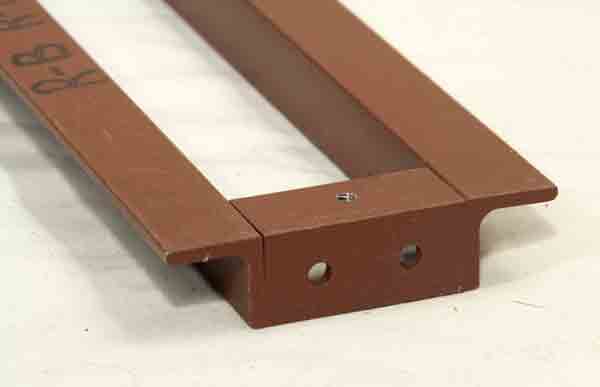

Welded-steel subroadbed sections; matching pieces for common LGB track-sections; custom sections available on request

Pros: Sturdy construction; easy to bolt sections together; can be used outdoors in the ground, suspended, or indoors held to the wall by brackets

Cons: Metal plates used to hold track to roadbed stand out visually in the garden

For this review I received four sample sections: a 30°, 2′-radius curved section; a 1′ straight; a 2′ straight; and a 2′-radius switch. All are well built and incredibly solid. Each piece has an end plate welded in place, with two holes drilled through for screws that are used to attach the sections. The sections go together easily and line up nicely when attached. Once joined, the assembly proved strong and withstood a fair amount of “torture.” I found that, as advertised, each section closely matched the geometry of LGB’s common track sections.

A roadbed system like this has many practical uses. It’s rigid enough to be used as a raised roadbed, and can be filled in later with dirt. The company’s website has photos of a number of railroads built so that the track is rather precariously perched several feet from the ground, using little more than this roadbed and supported by metal posts; yet the entire structure is stable. (The company sells brackets to hold it to such posts.) I can see this system being ideal for running along a fence or similar stretch of track, into a storage shed; under a house, etc., where you want an absolutely solid foundation for your track without a lot of extra structure to hold it in place. Laid on the ground as a subroadbed, it’s not going to move, twist, warp, or do anything to give your track any excuse to move out of alignment. Indoors, the sections can be used as a suspended roadbed system, secured to the wall by angle brackets or any other means you can come up with.

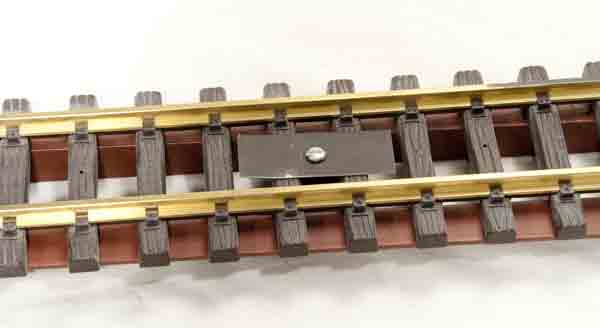

The only thing that stood out as being remotely objectionable about this system concerns the metal plates used to clamp the track to the roadbed. At 1″ by about 3″, they stand out visually if the track is on the ground. In any kind of an elevated setting, where you cannot easily see the top of the track, you’ll likely never know they’re there. Having said that, zip ties can easily be used to attach the track to the steel roadbed in these instances and be far less obtrusive.

Railbed Systems makes these sections to match LGB’s track geometry, but the roadbed sections will also easily fit the similar or identical track sections of other manufacturers as well: certainly the straight sections, the 2′-radius curves, and switches. If you’re using curves not covered by the company’s stock track sections, Railbed Systems will custom build roadbed to meet your needs.

Overall, this is a structural roadbed system that will undoubtedly give your railroad a solid foundation, which is paramount for smooth operations and longevity.