1:20.3 scale, gauge 1, ready-to-run, East Broad Top 2-8-2

Rich Yoder Models

7 Edgedale Court

Wyomissing PA 19610

Price: $2,995

Email: richyoder@richyodermodels.com

Web site: www.richyodermodels.com

All metal, electrically powered model of an EBT Mikado; 24V motor; sprung wheels; directional lighting; sound ready; battery ready. Dimensions: length (loco & tender), 38″ long over couplers; width, 5½”; height, 7½”. In 1:20.3 scale, this works out to 64’3″ x 9’3½” x 12’8″, respectively

Pros: Finely detailed, all-metal model of EBT locomotives Nºs 14 and 15; smooth operation from large 24V Pittman motor and sealed gearbox; all wheels insulated and sprung; all axles have ball bearings; pre-wired for sound and/or tender battery operation with track/tender switch; will operate on curves down to 4′-radius; correct scale/gauge combination

Cons: Long frame and stiff springs may be troublesome on rough track; track/tender switch incorrectly wired for battery operation unsightly track pickup shoes

The engines from RYM are supplied in the “tourist” paint scheme, with clean, black paint, white edges to the walkways, and polished brass boiler bands. (Old style, all-black livery is available on request.) Two engine numbers are offered and the differences between the two locomotives are faithfully modeled. The most obvious difference is that Nº 15 has piping outside the air tank on the left, while Nº 14 has none. They also have different colors on the smokebox number plate.

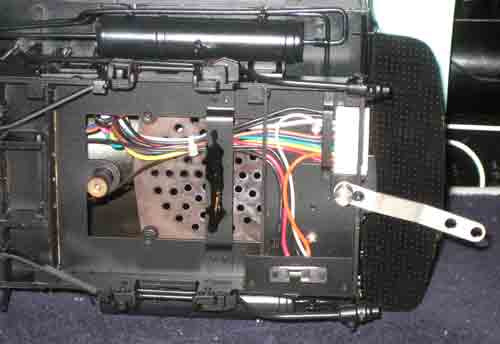

The model operates on 0-24V DC and runs smoothly and quietly. RYM does a thorough test in the factory before shipping, running each locomotive for an extended period. Performance is more than adequate on 16-20V. My review-sample of Nº 15 now has two 9.6V battery packs in the tender, a total of 19.2V. A switch under the cab selects track or tender battery power (the switch is wired incorrectly for tender power but a modification is shown on RYM’s web site.) Plungers collect power from the tires of the first and last (flanged) drivers; those are the only pickups supplied, so track-power devotees may want to add more, perhaps on the tender wheels, as the wiring to the engine is already provided. All the wheels are insulated.

A ten-pin connector under the cab links to cables pre-installed in the tender for battery, sound, and/or radio control. (Suggested wiring is detailed on the RYM web site.) This cable extends into the water tank but the only connections, as supplied, are to the backup light, which is correctly fitted on the right, rear corner of the tank. Both the front and back lights are LEDs and they only light up when the locomotive is heading in the appropriate direction. They are white LEDs, so a little translucent yellow paint might make them look “older.”

RYM says the locomotive will negotiate 4′-radius curved track but it will obviously look much better on wider curves. I measured the back-to-back of the wheels at 1.570″, which is very close to that recommended by the G1MRA for garden-railway operation. All the axles have ball bearings (including the tender, making the engine very free running) and the drivers are sprung, with lighter springs on the center, blind drivers. The chassis is correctly prototypical, with the bar frames and springs modeled.

Correct-pattern wheels with appropriate counterweights are fitted (larger on the second and third [blind] drivers), and correctly spoked wheels are supplied on the front and rear trucks and the tender. Engine trucks have sprung plungers sliding on the underside of the pilot and cab, besides the springs on the pivots. The rear truck has an additional spring in front of the axle, and all these springs make the rear truck quite rigid. If you are planning to run on rough, outdoor track, as I do, you might loosen the truck a little (details on the RYM web site).

The boiler is attached to the frames by two large screws under the cab and a third under the smokebox. To remove it, the reversing lever must also be disconnected and the pilot/smokebox braces need a careful tap to push them upwards. Sand pipes are still hanging down below the boiler when it is removed, so great care must be exercised to prevent any damage. When the boiler is removed, full access is provided to the interior from the firebox. The firebox will accept a 2.5″ speaker, mounted on the frame, and a “chuff” cam is provided, pre-wired, on the rear axle. The large motor is mounted in the boiler, just ahead of the firebox, over the rear axle, with a sealed gearbox on the third axle, connected via a universal joint.

The tender similarly comes apart with just a few screws, providing full access to the interior of the water tank. The tank filler hatch is hinged so that it is fairly easy to mount an on/off switch or charger jacks.

The front and rear cab doors are hinged, and the boiler fittings are fully modeled. The interior of the cab is a prototypical light green, though a little dirt would reduce the bright effect. The whistle and bell on the boiler are connected to the cab by a fine brass wire painted black, and the bell rope runs correctly through a small loop on the steam dome.

The locomotive rests happily on its side if you want access to the underside for oiling, etc., as there are no small details protruding beyond the walkways.

I really like the engine, which sits in pride of place on my mantel shelf when not running on the railroad. I’m sure you will be pleased with the build quality and level of detail of this beautiful model.