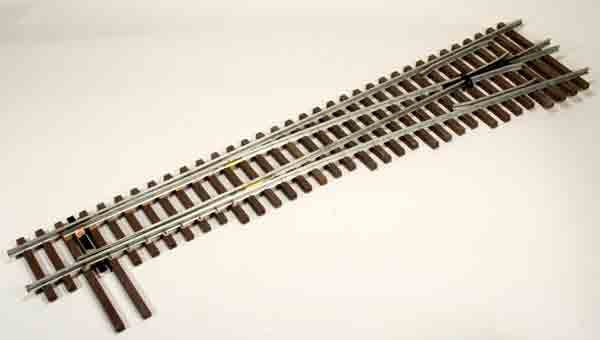

Gauge 1, code 250, stainless steel, #6 turnout

Sunset Valley Railroad

21616 23rd St. Ct. E

Lake Tapps WA 98391

Price: $118.50

Web site: www.svrronline.com

Stainless-steel rails spiked to plastic ties; scaled for 1:32 scale; length, 26¼”

Pros: Sturdy construction; accurate gauge; smooth operation

Cons: None

Because stainless steel is a harder metal, it’s more difficult to cut and bend; you definitely need a rail bender. Also, soldering to stainless steel is more problematic than to brass. It’s not impossible, but you may find yourself relying on mechanical joints instead of solder. The other drawback of stainless steel rail is that-again-it’s stainless. The very aspect that keeps the rail conducting electricity also prevents it from weathering to a more prototypical color. Like aluminum rail, if you want it to look rusty and dirty, you’ll have to paint it.

Sunset Valley’s code 250, stainless-steel rail has a very good profile and is exactly .250″ tall. It’s the same profile as the company’s other rail, so compatibility shouldn’t be a problem.

The turnout sent for review is what Sunset Valley calls their “mainline” #6 switch, meaning the tie size and spacing is similar to that of standard-gauge railroads. At 1:32 (#1 scale), the ties measure 8″ wide, spaced on 2′ centers. That’s identical to the width of a standard railroad tie, and very close to typical tie spacing, which varies between 20″ and 24″. Tie lengths vary as the tracks diverge along the switch, but are also typical of standard-gauge tie lengths. The “#6″ designation refers to the sharpness of the switch; for every 6 units of length, there’s 1 unit of distance separating the diverging rails. A #6 switch is-roughly-the equivalent of an 8′ radius curve, though the track diverges on a straight tangent, not a curved radius, so it’s technically inaccurate to describe it as such. The switch itself is 261/4” long. A #6 switch will take up a fair amount of space in a garden railroad, and the company offers smaller switches for those who are limited on space.

Ties are UV-stable plastic. Rails are spiked down to the ties, with the ends of the spikes bent underneath the ties to hold them down. The company also offers “narrow gauge” switches. The only difference between the two is the tie spacing. I’ve had Sunset Valley’s brass switches in my yard for three years, and they’ve proven to be smooth and reliable in operation. I have every confidence that the stainless-steel switches will be no different.

It’s good to see a quality track manufacturer like Sunset Valley delving into stainless-steel rail. With the price of brass on the increase, its cost savings over stainless are quickly being eroded, so we may as well take advantage of the benefits stainless has to offer.